GB - 8

2.4 Technical data

Product description

1) The typical inverter ratings are only assignment references for the components. The drive powers

are dependent on the connected motors and must be designed accordingly.

2) The max. short time current limit is specied for 1 minute. The overload cycle is 300 seconds. This

corresponds to duty class 2 EN 60146-1-1.

3) The current data are based on a fundamental frequency component of g=0,75. The fundamental

frequency component or the effective value of the input current is dependent on load and line supply

conditions. At uncontrolled B6 converters the phase angle cosφ1 can be set to one, so the value of

the fundamental frequency components is equal to the value of the power factor.

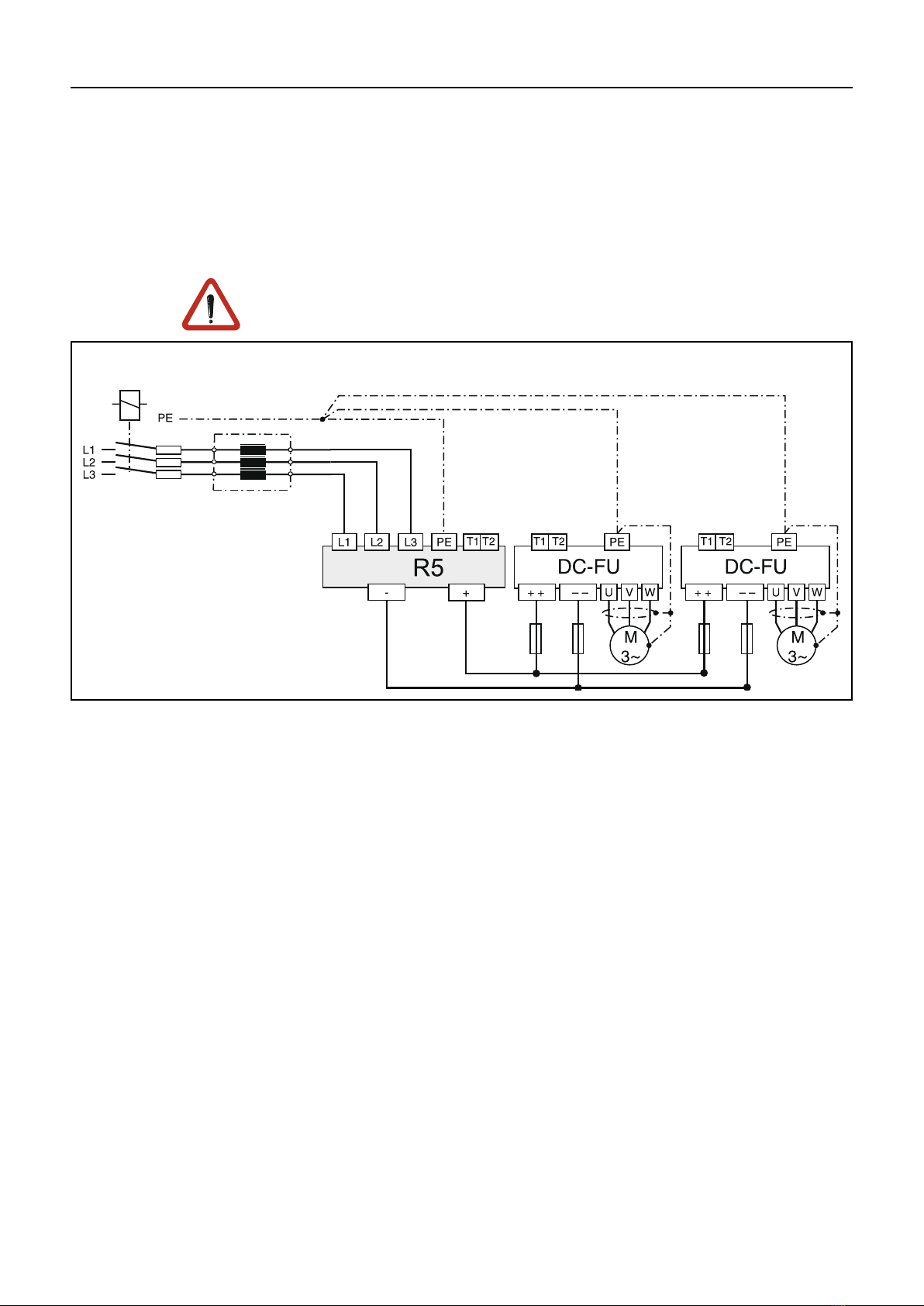

The units are not short-circuit proof without corresponding dimensioned fuses.The max.

loadable DC link capacity is 100000 µF. Exceeding the capacity triggers the error "charge

time out" (E.cto). Do not charge the DC link during the load cycle.

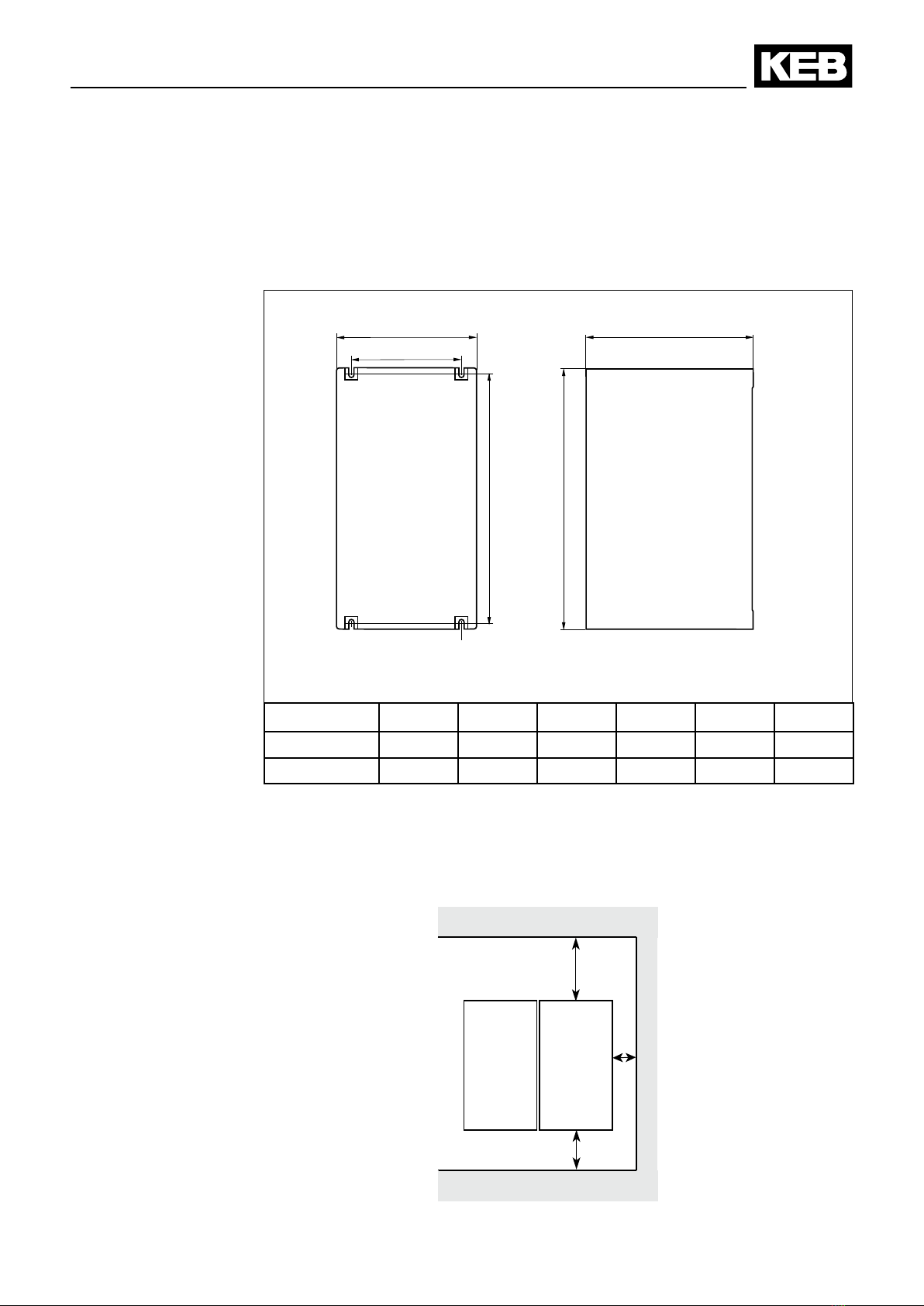

Rectiersize 19 23 25 27 28 29

Housing size R R R U U U

Chargeable inverter power 1) [kW] 30 75 110 160 200 250

DC nominal output current [ADC]90 180 270 380 470 610

Max. short time current 2) [AAV]135 270 405 570 705 915

OL current [ADC]153 306 459 646 799 1037

Input current 3) [ARMS]79,8 147,5 221 312 386 500

Mains voltage [V ACRMS]305…504 +/- 0%

Phases 3

Output voltage [V DC] 430…713

Maximal permissible mains fuse [A] 100 200 350 500 710 710

I2t mains fuse [A2s] <19.100 <128.000 <236.000 <423.000 <1.062.000 <1.062.000

Supply line cross section (min) [mm2]35 95 150 2x150 2x185 2x185

Supply line cross section (max) [mm2]95 150 150 2x185 2x185 2x185

DC line cross section (min) [mm2]50 120 150 2x150 2x150 4x95

DC line cross section (max) [mm2] 95 150 150 4x185 4x185 4x185

Storage temperature [°C] -25…70

Operation temperature [°C] -10…45

Climatic category (EN 60721-3-3) 3K3

Protective system IP20 IP00

Power loss at nominal operating [W] ca. 220 ca. 400 ca. 600 ca. 1050 ca.1200 ca.1600

Max. heat sink temperature [°C] 90

Internal braking option Option

Max. braking current [A] 133 133 200 250 250 250

Min. braking resistor [Ohm] 6 6 4 3,2 3,2 3,2

Typ. braking resistor [Ohm] 15 6,7 4,3 4,3 3,2 3,2

Line cross section braking resistor [mm2]35…95 16…185

Weight [kg] 28 49 54 56