Table of Contents

1. Introduction..................................................................................................... 5

1.1 Preface..................................................................................................................................5

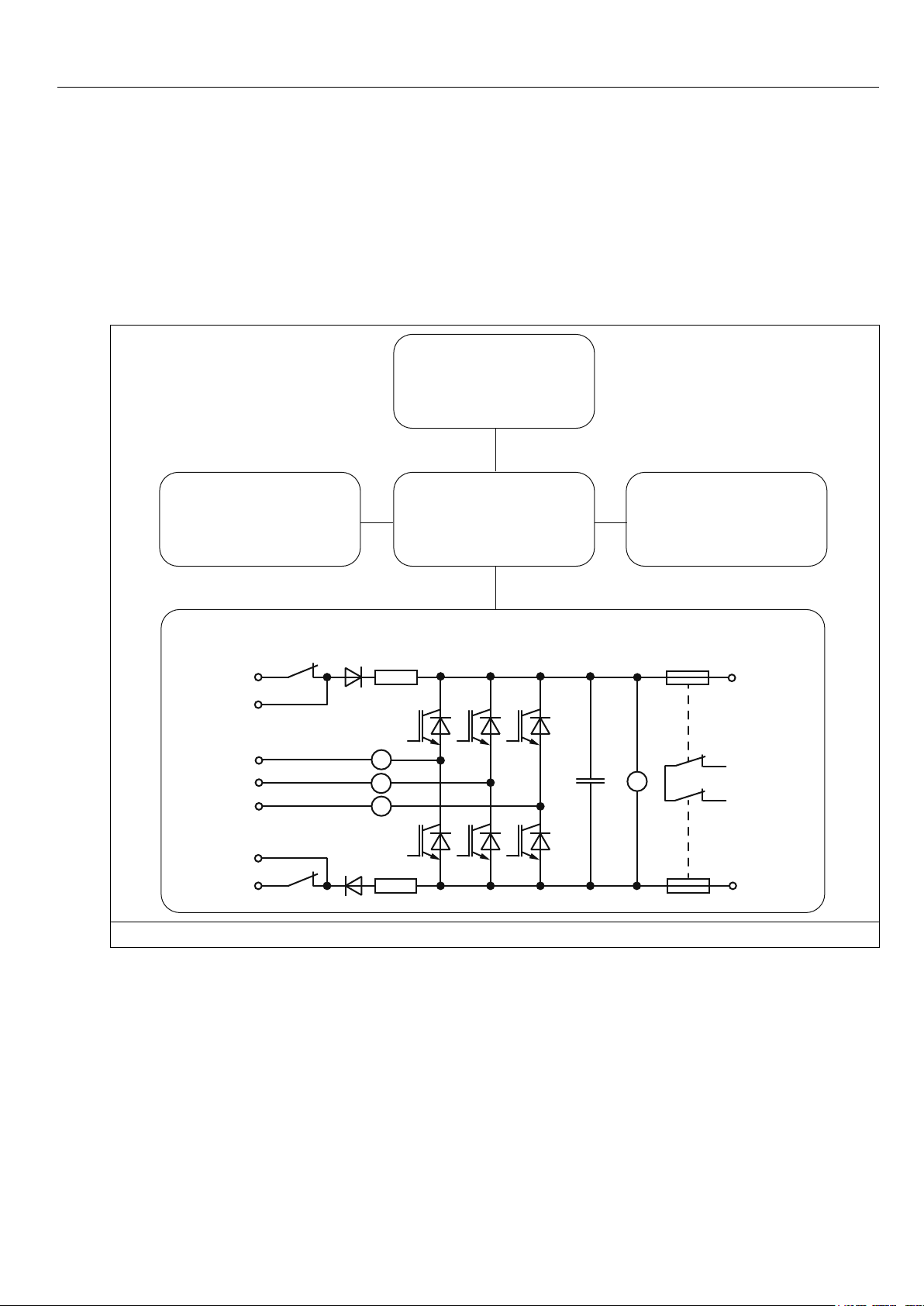

1.2 Product description.............................................................................................................5

1.3 Validity and liability .............................................................................................................7

1.4 Copyright..............................................................................................................................7

1.5 Speciedapplication...........................................................................................................7

1.5.1 Standard operation ................................................................................................................8

1.5.2 Abnormal operation ...............................................................................................................8

1.6 Unitidentication ................................................................................................................9

2. Safety Instructions ....................................................................................... 10

2.1 General instructions..........................................................................................................10

2.2 Transport, storage and installation..................................................................................10

2.3 Electrical connection......................................................................................................... 11

2.4 EMC instructions ...............................................................................................................14

2.5 EMC conform installation .................................................................................................14

3. Technical Data .............................................................................................. 15

3.1 Overload (OL) function......................................................................................................16

3.2 Operating conditions.........................................................................................................17

3.3 Accessories........................................................................................................................18

3.4 Options ...............................................................................................................................19

3.4.1 Ferrite rings..........................................................................................................................20

3.5 Dimensions and weights...................................................................................................21

3.5.1 Dimensions air cooling system mounted version.................................................................21

3.5.2 Commutation reactor / mains choke ....................................................................................22

3.5.3 Radiointerferencelter(side-mounted) ..............................................................................23

3.5.4 Synchronization unit ............................................................................................................25

3.5.5 Fuse holder with cover.........................................................................................................26

4. Installation..................................................................................................... 27

4.1 EMC-compatible control cabinet installation..................................................................27

4.2 Installation instructions ....................................................................................................27

4.3 Connection of the COMBIVERT R6 ..................................................................................28

4.3.1 General description of inverter input terminals ....................................................................28

4.3.2 Connection terminals of the power circuit............................................................................30

4.3.3 Connections of the control board.........................................................................................32

4.3.4 Connection of the synchronization unit................................................................................33

4.4 Connection power unit R6-S without UL .........................................................................34

4.4.1 Powersupplyandregenrativeoperationatinvertercurrent≤invertercurrentofone

COMBIVERT R6-S without UL ............................................................................................34

4.5 Connection power unit R6-S with UL...............................................................................36

4.5.1 Powersupplyandregenrativeoperationatinvertercurrent≤invertercurrentofone

COMBIVERT R6-S with UL .................................................................................................36

4.5.2 Power supply and regenerative operation at parallel operation with one frequency

inverter.................................................................................................................................37

GB - 3

Table of Contents