3

Table of contents

Table of contents

1. Preface............................................................................................................. 4

1.1 Information on special measures.......................................................................................4

1.2 Documentation.....................................................................................................................4

1.3 Validity and liability .............................................................................................................4

1.4 Copyright..............................................................................................................................5

1.5 Pay attention to markings...................................................................................................6

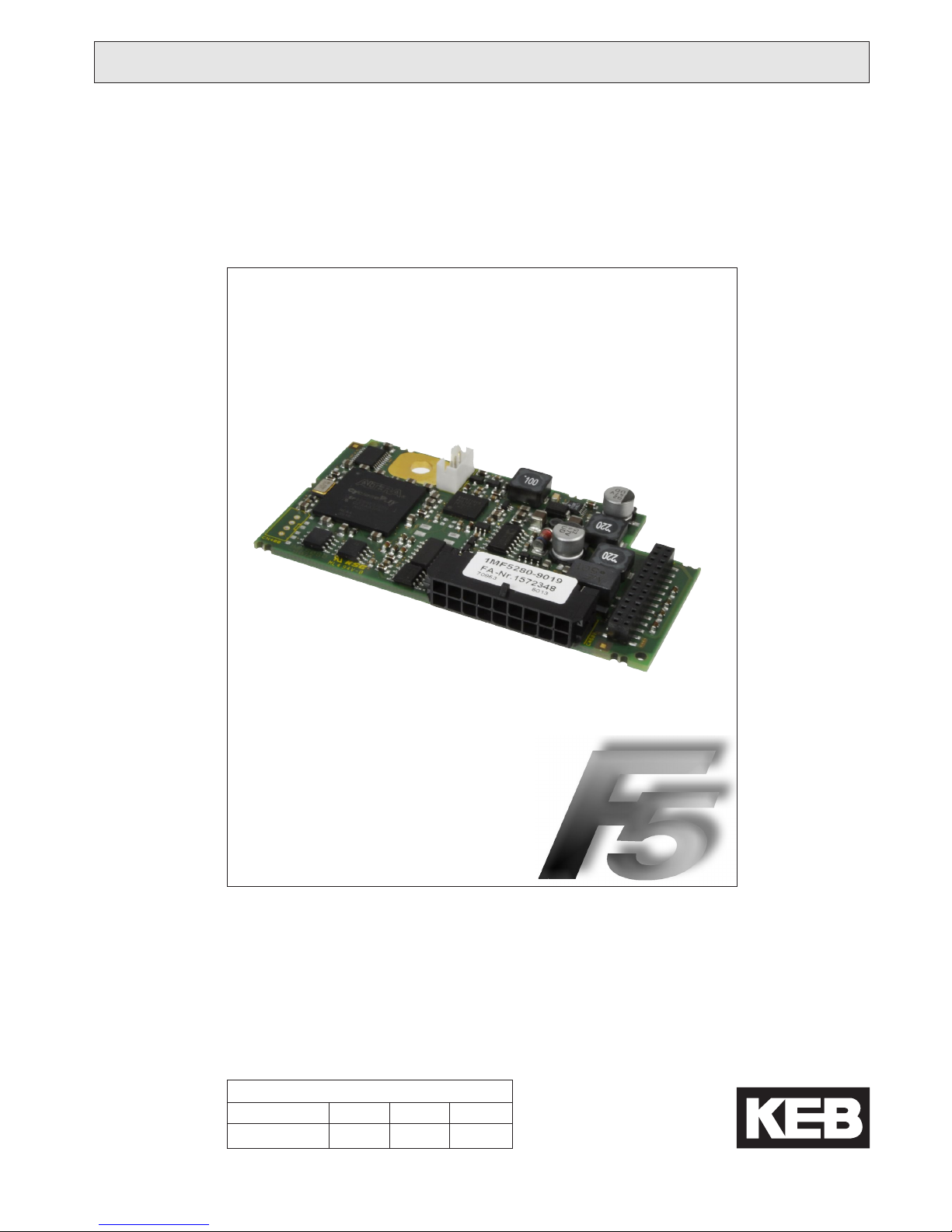

2. Product Description ....................................................................................... 7

2.1 General .................................................................................................................................7

2.2 Operation..............................................................................................................................7

2.2.1 Operation TTL with zero singal ..............................................................................................8

2.2.2 Operation BiSS and Endat.....................................................................................................8

2.3 Material number ...................................................................................................................9

2.4 Scope of delivery (option or replacement delivery) .......................................................10

2.5 Mechanical installation .....................................................................................................10

3. Description of the Interface ......................................................................... 11

3.1 Voltage supply ................................................................................................................... 11

3.2 Channel 1............................................................................................................................ 11

3.2.1 Specications....................................................................................................................... 11

3.2.2 Description of X3A ...............................................................................................................12

3.3 Connenction of the encoder Biss + 1 Vpp / EnDat + 1 Vp ..............................................13

3.3.1 Encoder cable for evaluation without 1 Vpp-signals ............................................................14

3.3.2 Encoder cable for evaluation with 1 Vpp-signals .................................................................14

3.3.3 Encoder line length ..............................................................................................................14

3.3.4 Tested encoders ..................................................................................................................15

3.3.5 Connection of the encoder cable shield...............................................................................15

4. Start-up.......................................................................................................... 16

4.1 Encoder 1 status (Ec.37) ...................................................................................................16

4.1.1 Error Messages ...................................................................................................................17

4.1.2 Encoder 1 read/write (Ec.38, if supported by the encoder) .................................................17