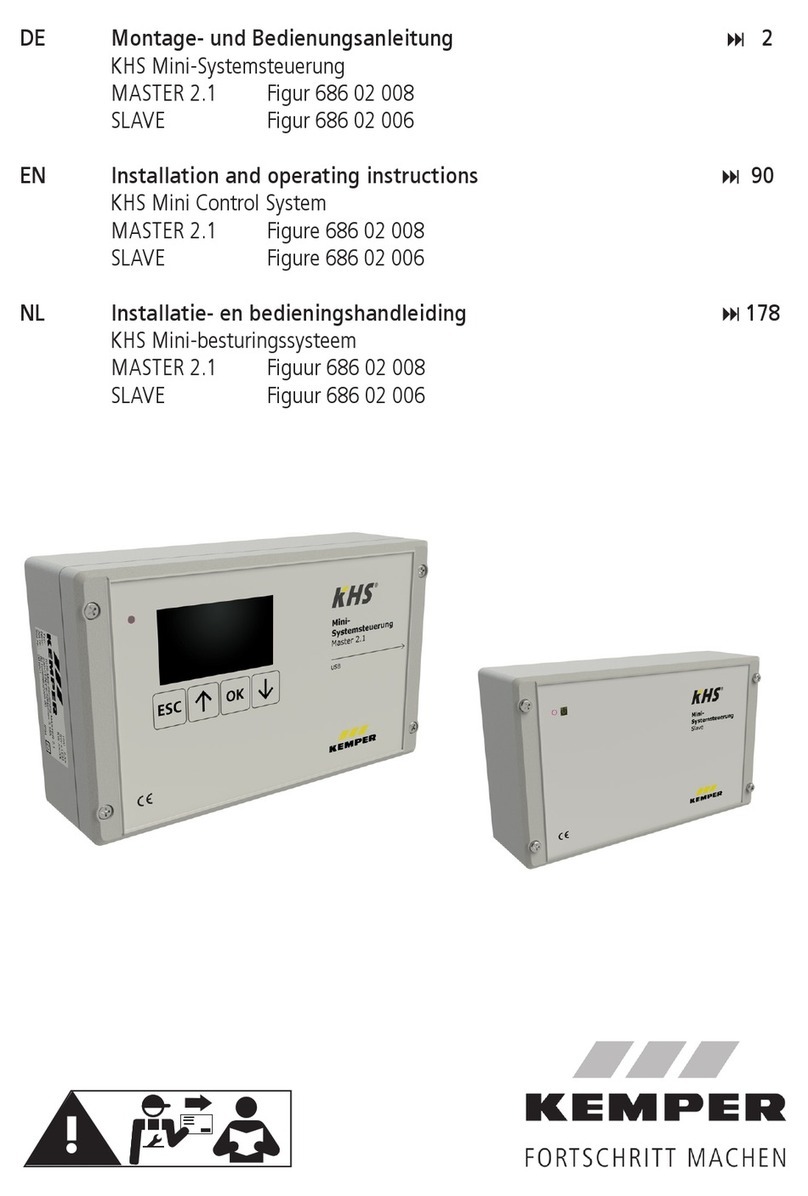

Manual KHS Mini System Control MASTER

TABLE OF CONTENTS

1. GENERAL INSTRUCTIONS: ................................................................................................................1

2. AREA OF APPLICATION....................................................................................................................2

2.1 Operating modes for the water exchange ....................................................................... 2

2.2 KHS MASTER/SLAVE technology ....................................................................................... 2

2.3 Water exchange groups.....................................................................................................2

3. SAFETY.............................................................................................................................................3

3.1 Safety Instructions ..............................................................................................................3

3.2 Hazards if the safety instructions are not complied with ............................................... 3

3.3 Unauthorized alteration and spare part fabrication....................................................... 3

3.4 Unauthorised modes of operation.................................................................................... 3

4. TECHNICAL DATA ............................................................................................................................4

5. CAN BUS SYSTEM OVERVIEW..........................................................................................................5

5.1 Layout variants ................................................................................................................... 5

5.2 Terminal resistance ............................................................................................................ 6

5.3 Connection of terminal resistor ........................................................................................ 6

6. ASSEMBLY........................................................................................................................................7

6.1. Wall mounting.................................................................................................................... 7

6.2 Electrical installation KHS Mini System Control ............................................................... 8

6.2.1Terminal description -MASTER- and -SLAVE-.....................................................................................8

6.2.2Detailed illustration of the terminals for cable entry ......................................................................9

6.2.2.1Power supply connection ....................................................................................................................9

6.2.2.2Connection of KHS Isolating valve with servo-drive (Figure 686 00) ...................................................9

6.2.2.3Connection of KHS Isolating valve with spring reset servo-drive (Figure 686 01)...................10

6.2.2.4CAN bus connection ...........................................................................................................................10

6.2.2.5Connection of external switch .........................................................................................................11

6.2.2.6Connection of KHS-CONTROL-PLUS flow measurement valve (Figure 638 4G).......................12

6.2.2.7Connection of KHS Temperature sensor Pt 1000 (Figure 628 0G) ..............................................13

6.2.2.8Connection of KHS drain with overflow monitor (Figure 688 00) .............................................13

6.2.2.9Connection of water sensor (Figure 620 00) ...................................................................................14

6.2.2.10Connection of floating alarm relay ..............................................................................................14

7. COMMISSIONING ................................................................................................................... 15