theOSCterminalontherearpanel,3.15kHz

based

onDINor3.0kHzbasedonJISand

CCIRf

used

forrecordingand

drift

meterselfcalibra-

tion.

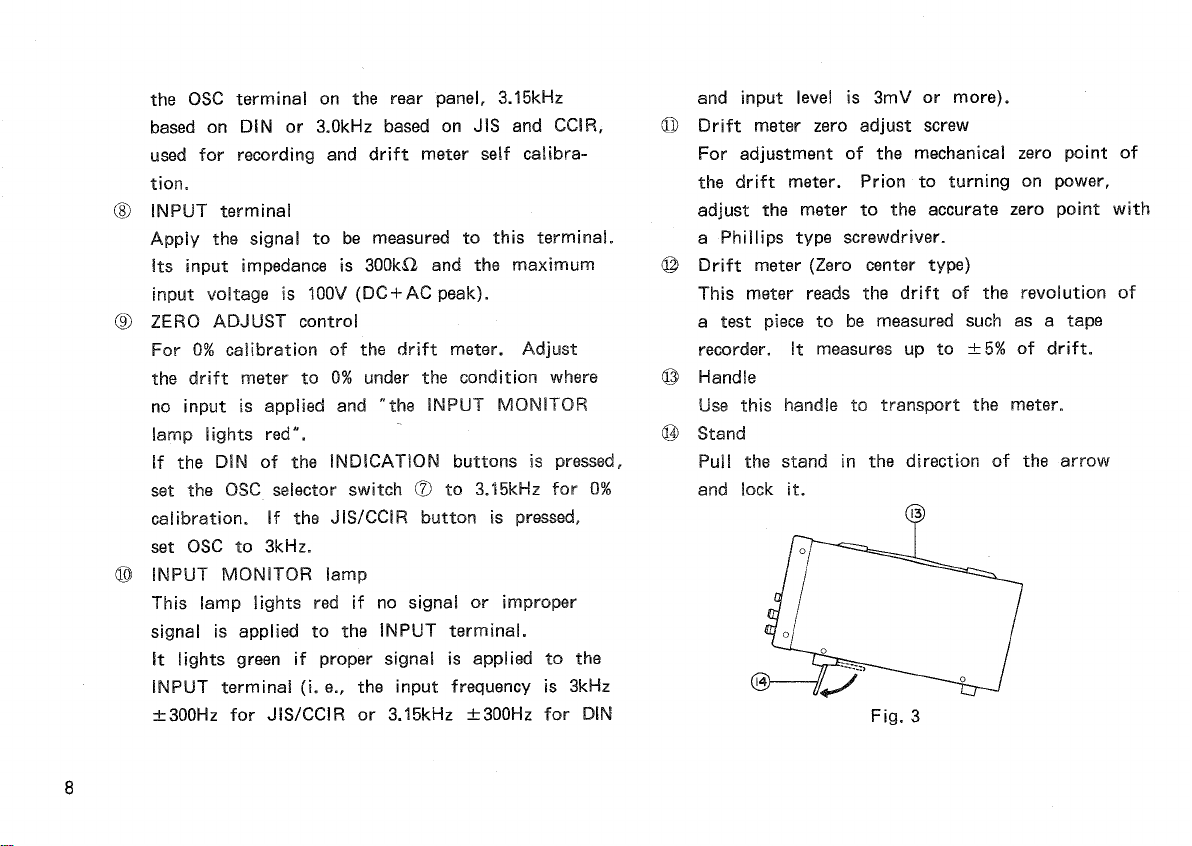

®

INPUT

terminal

Applythesignaltobemeasuredtothisterminal.

Its

inputimpedanceis300kOandthemaximum

inputvoltageis100V

(DC

+ AC

peak).

@ZERO

ADJUST

control

For

0%calibrationofthe

drift

meter.Adjust

the

drift

meterto0%undertheconditionwhere

noinputisappliedand"the

INPUT

MONITOR

lamplightsred".

IftheDINoftheINDICATIONbuttonsis

pressed,

set

theOSCselectorswitch© to3.15kHzfor0%

calibration.Ifthe

JIS/CCIR

button

is

pressed,

set

OSCto3kHz.

©

INPUT

MONITORlamp

This

lamplightsredifnosignalorimproper

signal

isappliedtothe

INPUT

terminal.

Itlightsgreenifpropersignalisappliedtothe

INPUT

terminal

(i.e.,

theinputfrequencyis3kHz

±300Hzfor

JIS/CCIR

or3.15kHz±300HzforDIN

and

inputlevelis3mVormore).

©Driftmeterzeroadjustscrew

For

adjustmentofthemechanicalzero

point

of

the

drift

meter.Priontoturningonpower,

adjust

themetertotheaccuratezero

point

with

a

Phillipstypescrewdriver.

©Driftmeter(Zerocentertype)•

This

meterreadsthe

drift

oftherevolutionof

a

testpiecetobemeasuredsuchasa tape

recorder.Itmeasuresupto±5%of

drift.

©Handle

Use

thishandletotransportthemeter.

©Stand

Pull

thestandinthedirectionofthearrow

and

lockit.

Fig.

3