DESCRIPTION & SPECIFICATIONS

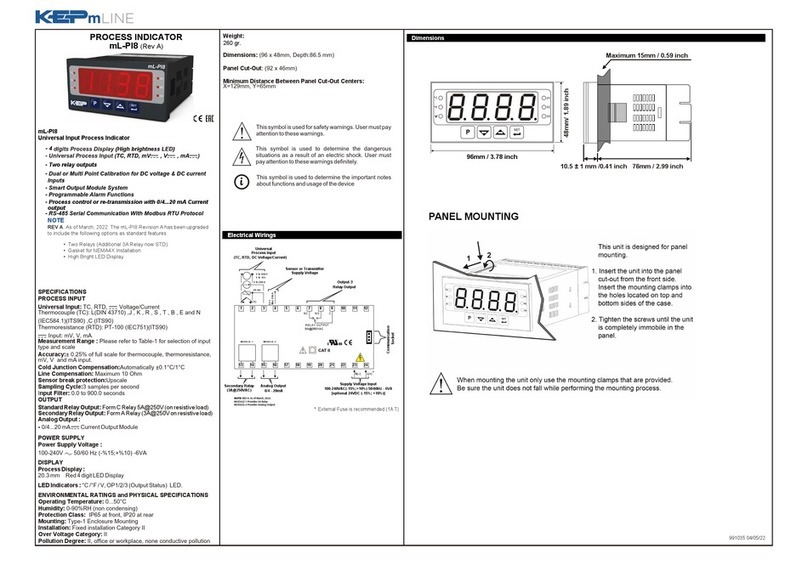

Featuring 6 digits of bright, 7-seg ment LED dis plays,

this unit is an integrating to tal izer/rateme ter which

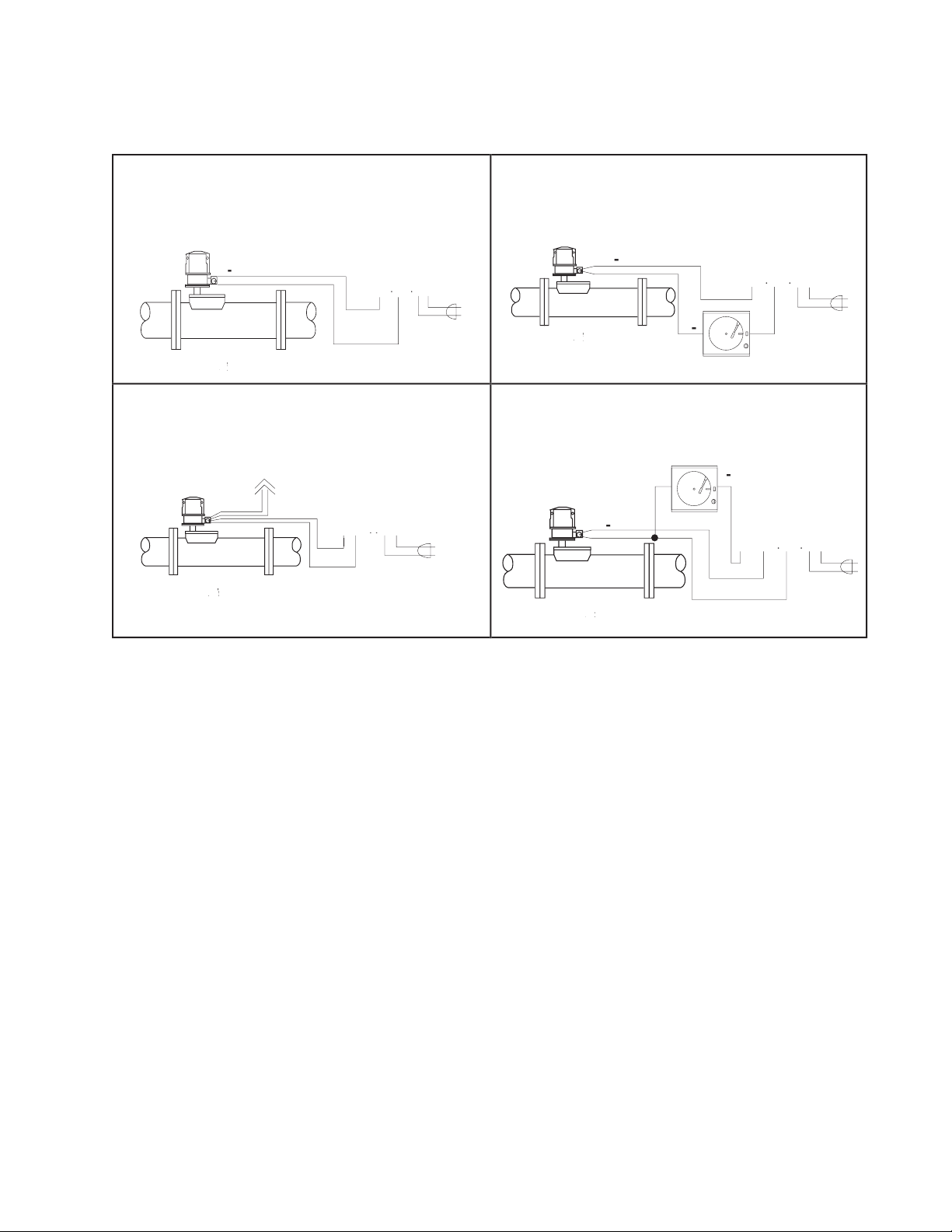

ac cepts ana log sig nal in puts. The unit can be fi eld

pro grammed to ac cept 0-20mA, 4-20mA, 0-5V, 0-10V

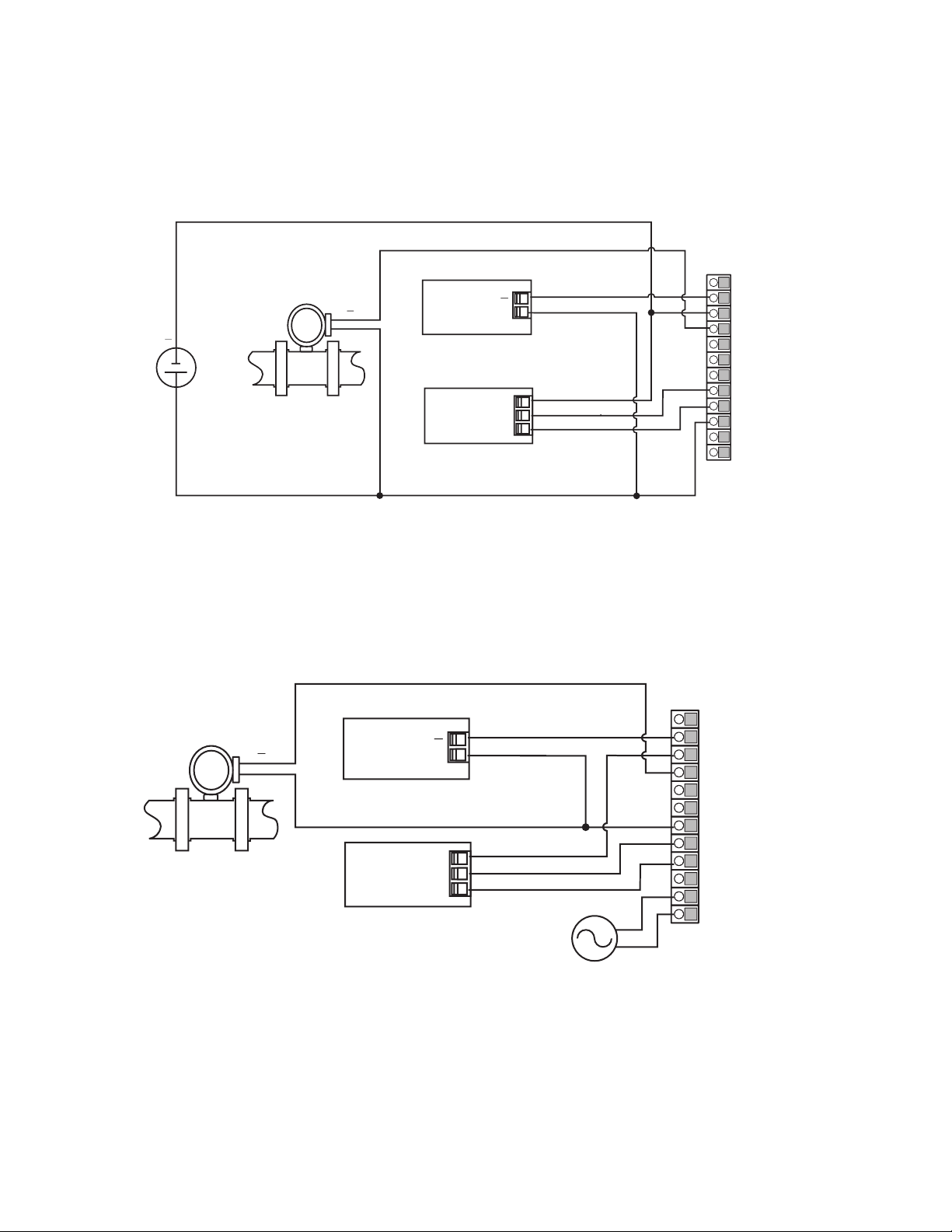

or 1-5V sig nals. A 4-20mA out put op tion is avail able

to control strip re cord ers or other peripherals. Two

as sign able set points are stan dard for two stage shut

off. The full scale setting is pro gram mable from the

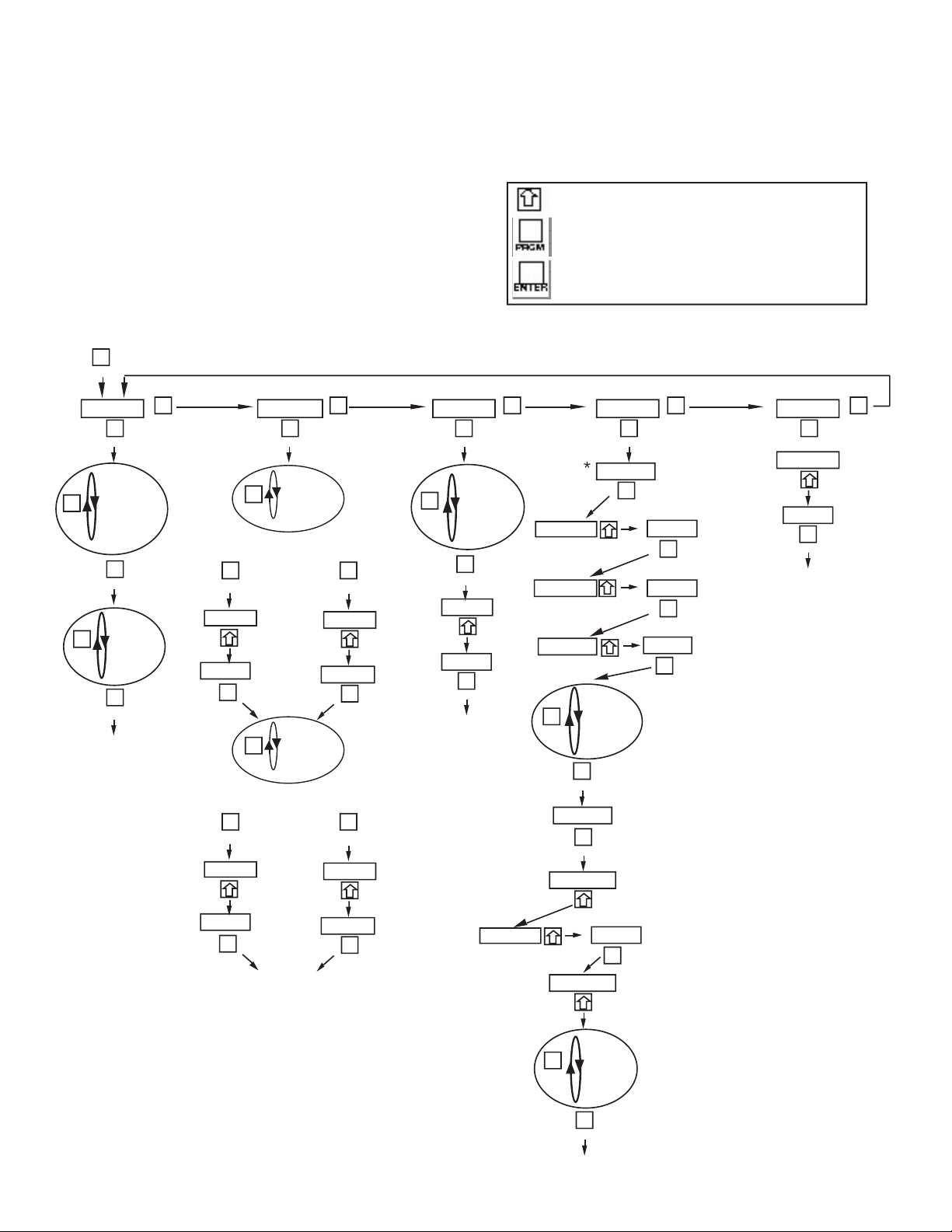

front pan el. By press ing the "view" but ton, the unit

will display: in te grated to tal, rate, peak or valley.

6 digit, .55" high, 7 seg ment, red orange,

110 VAC ± 15% or 12 to 24VDC.

Current: maximum 300 mA DC or 8.0 VA at rated AC

(AC pow ered units only) + 24VDC @

Operating: +41°F (5°C) to +130°F (+54°C).

Storage: -40°F (-40°C) to +200°F (93°C).

: EEPROM stores data for ten years if power

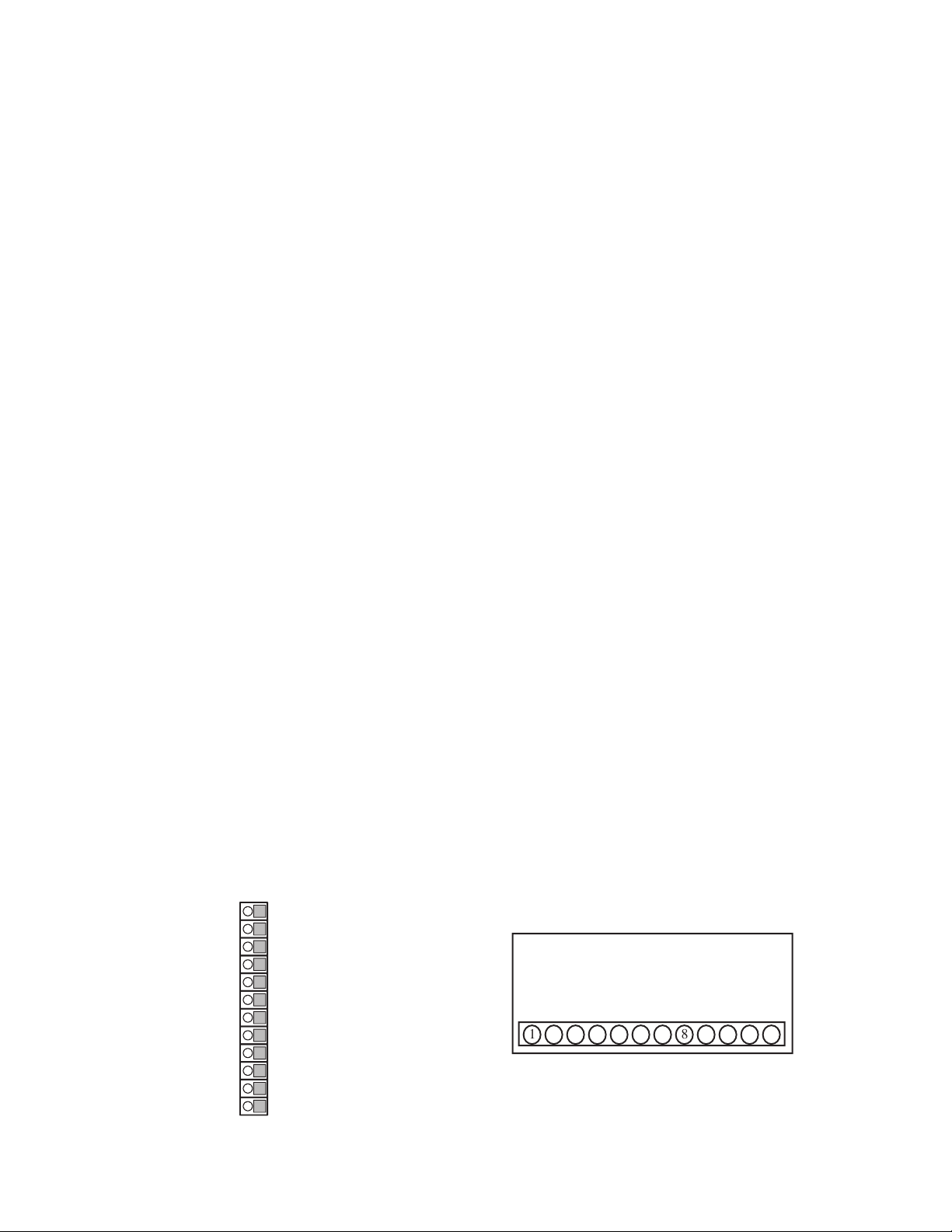

Front Panel: resets dis played val ues and control out-

Remote: 4-30VDC positive edge, resets totalizer and

Type: Open collector sinks 250mA from 30VDC when

Usage: rate alarm, total alarm, scaled pulse output

The full scale setting is pro gram mable

from the front panel. A sink ing driver gen er ates a cor-

re spond ing lin ear cur rent through the external devices.

The out put up dates with each update of the rate. Ac-

curacy is ±0.25% FS worst case. Compliance volt age

must be 3 to 30 VDC non in duc tive. (The unit can

provide the DC source as long as the drop across the

devices being driven does not ex ceed 21V).

Type: Linear 0-20mA, 4-20mA, 0-5V, 0-10V or 1-5V

se lectable from the front panel.

Current: 100Ω; Voltage: 115KΩ

The unit does all of the calibrations in ter -

nal ly. There are no potentiometers to adjust and the

unit never needs to be removed from the case.

Two control set points are provided. The

set point outputs can be as signed to rate or total or pulse

scaling. The unit comes stan dard with two open col-

lec tor control out puts. The out puts are pro gram mable

from 0.01 to 599.99 sec or latched until reset when

as signed to the total or pulse and a hys ter esis (alarm

range) when as signed to the rate.

Updates 5 times per sec ond, Accurate

Integrates from the rate reading and ac cu -

mu lates up to 6 digits of total count. The time base (sec-

onds, minutes, hours or days) and totalize conversion

factor are fi eld pro gram mable from the front panel.

: Decimal points, Scal ing from 0 to

59999 units per se lected time base, set points, in put

type, security lock code, and as sign ing out puts are all

pro gram mable from the front panel.

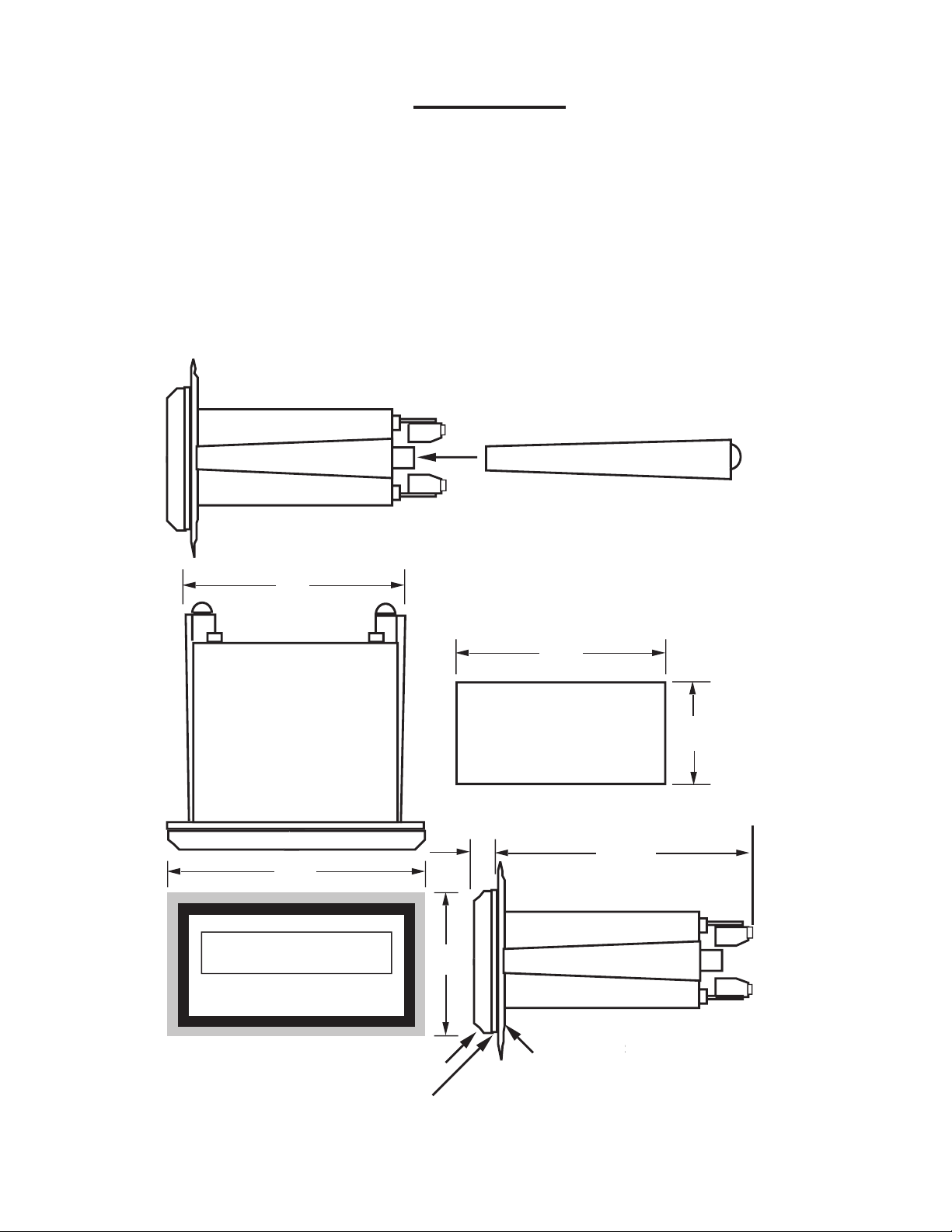

Standard 1/8 DIN, high im pact ABS plastic

case (NEMA 4/IP65 front panel).

Square Law: (above 5% of bottom range) 0.1%

(5V inputs .4%) Worst case over complete range: 2%

Will not drift more than 20

parts per million per °C from 5°C to 54°C