iHSF 600W 120110

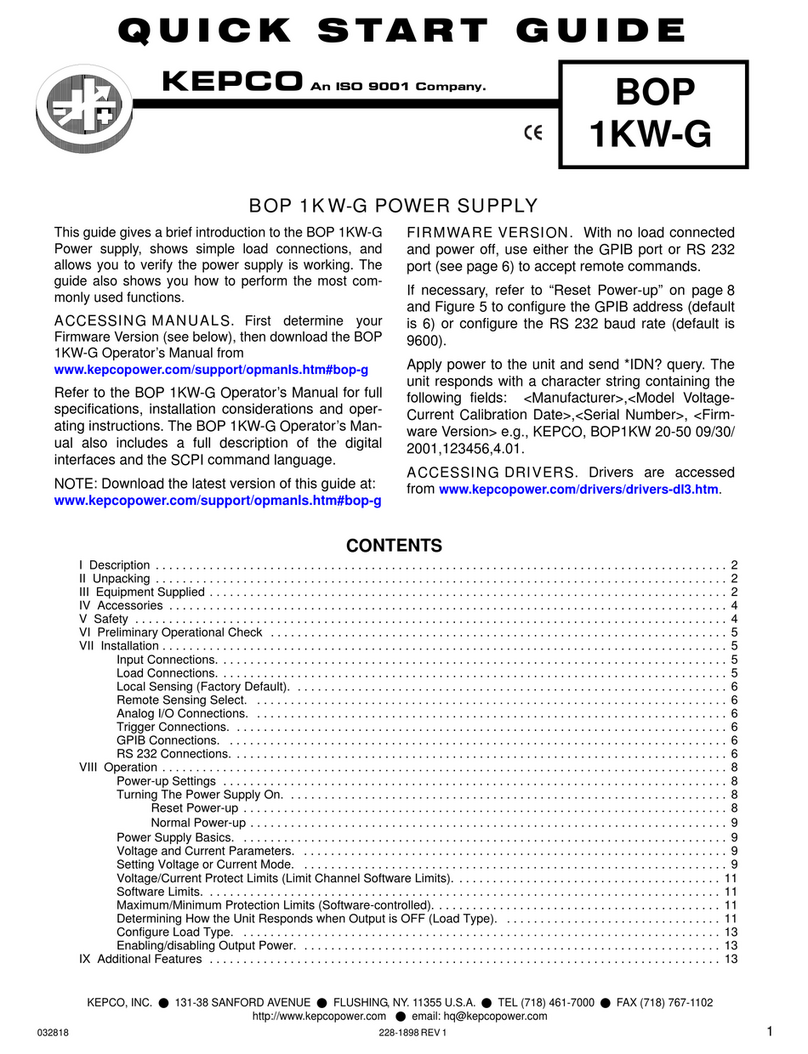

TABLE OF CONTENTS

SECTION PAGE

LIST OF FIGURES

FIGURE TITLE PAGE

LIST OF TABLES

TABLE TITLE PAGE

1 Introduction ........................................................................................................................................................ 1

1.1 Scope of Manual ............................................................................................................................................. 1

1.2 Description ...................................................................................................................................................... 1

1.3 Options............................................................................................................................................................ 1

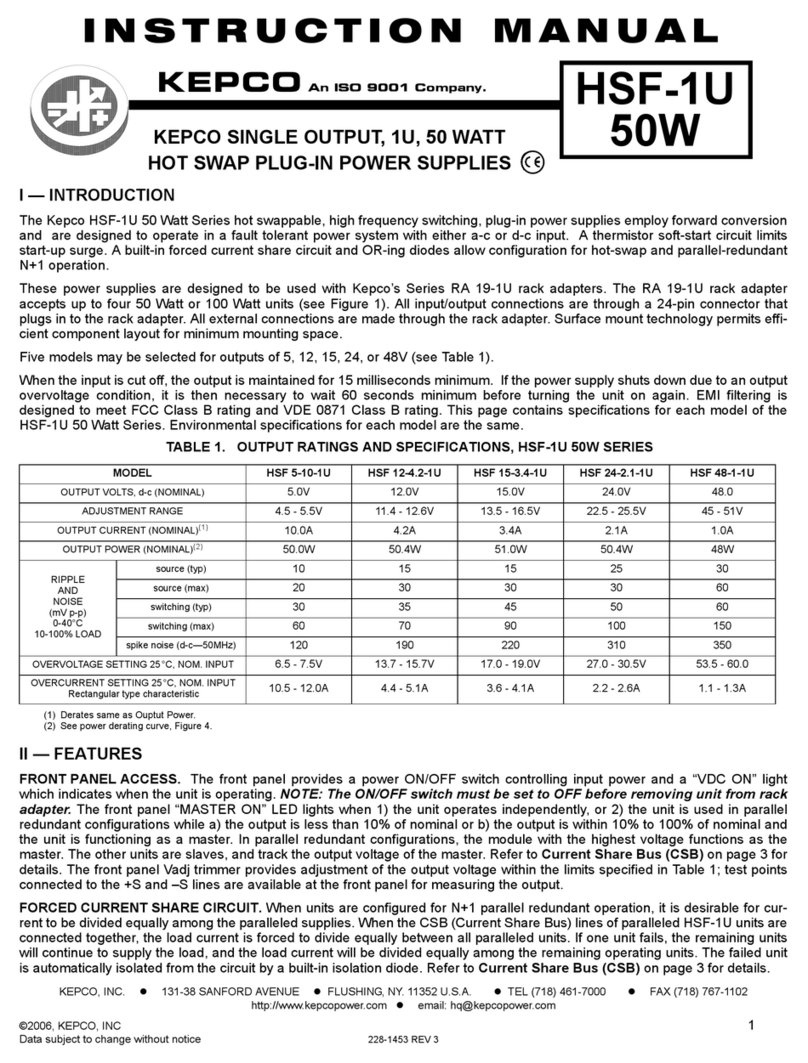

2 Specifications..................................................................................................................................................... 2

3 Features.......................................................................................................................................................... 6

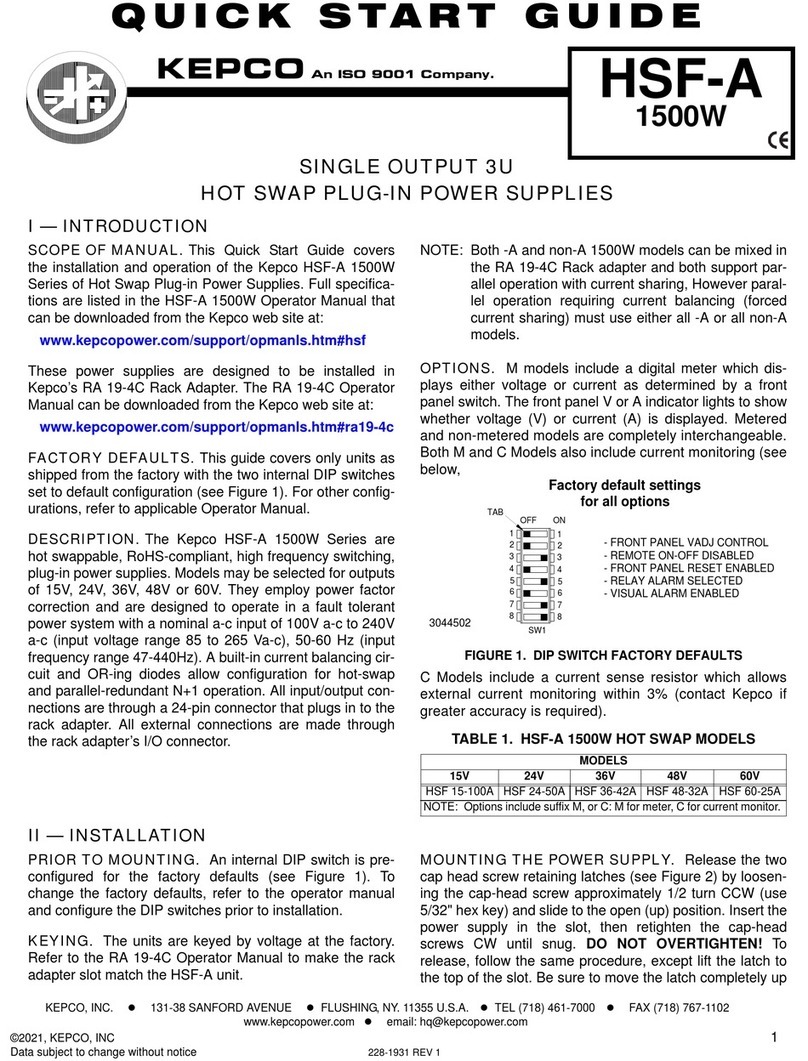

3.1 DIP Switch Configuration ................................................................................................................................ 6

3.2 Front Panel Access......................................................................................................................................... 7

3.3 Keying ............................................................................................................................................................. 8

3.4 Output Voltage Control ................................................................................................................................... 8

3.4.1 Front Panel Voltage Control......................................................................................................................... 8

3.4.2 Remote Voltage Control............................................................................................................................... 9

3.4.3 W Models ONLY: VDC ON/Alarm Indicator Function ................................................................................ 10

3.5 Remote On-Off.............................................................................................................................................. 10

3.6 Protection Circuits......................................................................................................................................... 11

3.6.1 Overvoltage And Overtemperature Protection ........................................................................................... 11

3.6.2 Overcurrent Setting and Protection............................................................................................................ 11

3.6.3 Fan Failure................................................................................................................................................. 12

3.6.4 Undervoltage.............................................................................................................................................. 12

3.7 Alarm Settings............................................................................................................................................... 12

3.7.1 Visual Alarm. .............................................................................................................................................. 12

3.7.2 Alarm Signals. ............................................................................................................................................ 12

3.7.2.1 Internal Isolated Relay Alarm .................................................................................................................. 12

3.7.2.2 Optically-Coupled Logical Alarm ............................................................................................................. 13

3.8 Local/remote Sensing ................................................................................................................................... 14

3.9 Retaining Latches ......................................................................................................................................... 14

4 Load Connection.............................................................................................................................................. 14

5 Connecting Multiple Power Supplies ............................................................................................................... 15

5.1 Adjusting the Voltage .................................................................................................................................... 15

5.2 Parallel Connections, Standard and C Models ............................................................................................. 15

5.3 Parallel Connections, W Models ................................................................................................................... 15

5.3.1 Minimum Load (W Models) ........................................................................................................................ 16

5.3.2 Voltage Set Restrictions (W Models) ......................................................................................................... 16

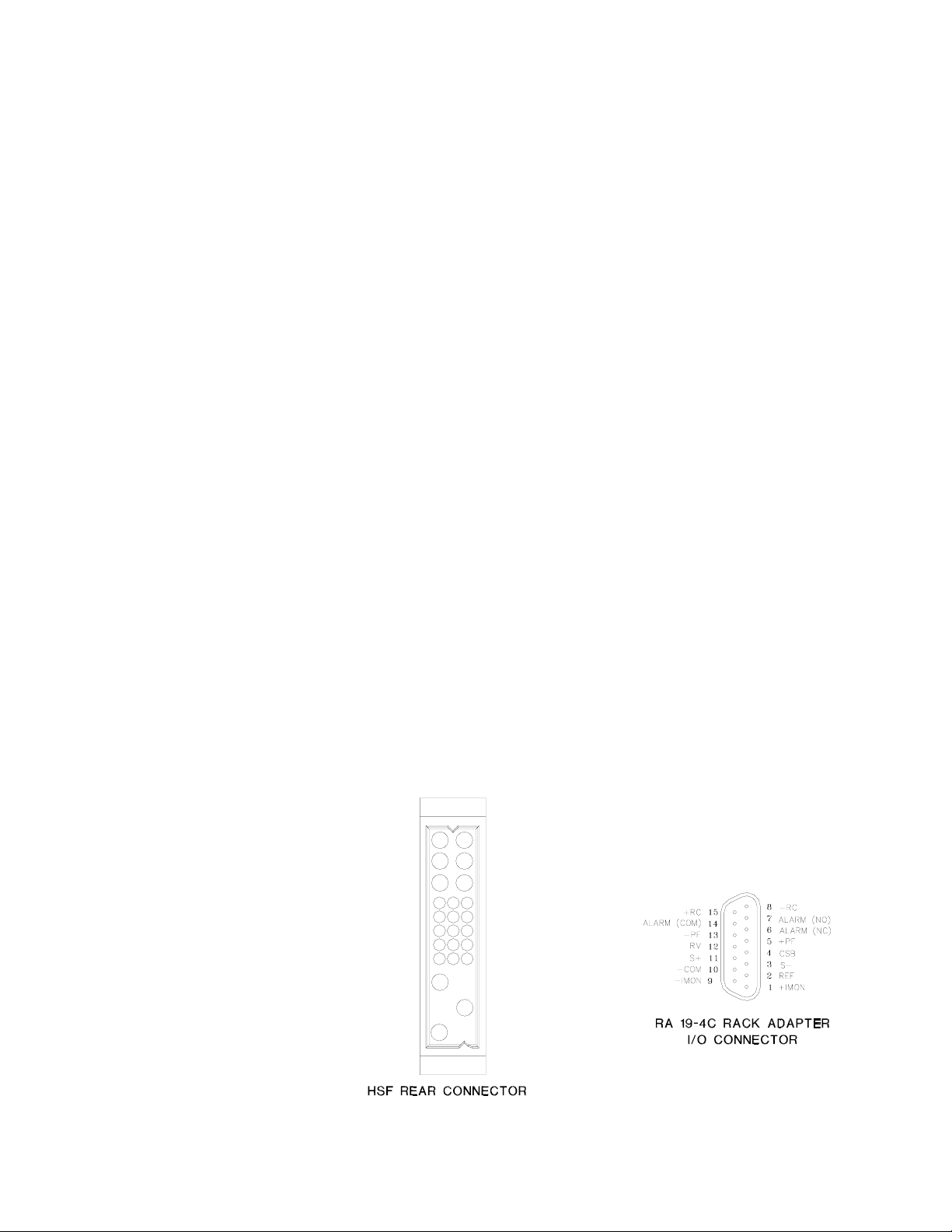

1 HSF Rear Panel Connector and RA 19-4C Rack Adapter I/O Connector .................................................. 1

2 Power Rating Vs. Temperature (Input: 95 to 264V a-c).............................................................................. 3

3 Mechanical Outline Drawing Of The HSF 600W Power Supply ................................................................. 6

4 DIP Switch Configuration............................................................................................................................ 7

5 Front Panel Controls, Indicators and Test Points ....................................................................................... 8

6 DIP Switch Settings for Control of Output Voltage ..................................................................................... 9

7 Connections For Remote Voltage Control ................................................................................................ 10

8 DIP switch settings for VDC ON/ALARM Power Options ......................................................................... 10

9 DIP Switch Settings for Using RESET button or Remote ON-OFF .......................................................... 11

10 DIP switch settings for Optically Coupled Logical Alarm .......................................................................... 13

11 Output Alarm Circuit Optically Isolated..................................................................................................... 13

12 ±PF Power Failure Optocoupler Timing Diagram..................................................................................... 14

1 HSF Rear Connector Pin Assignments ......................................................................................................2

2 Output Ratings and Specifications ..............................................................................................................3

3 Power Supply Ratings and Specifications ..................................................................................................4

4 Minimum Conditions for Relay and LED Operation ....................................................................................9

5 W Models: Conditions for VDC ON/ALARM LED Operation Powered by Output .....................................10