32 / 180

2017/11

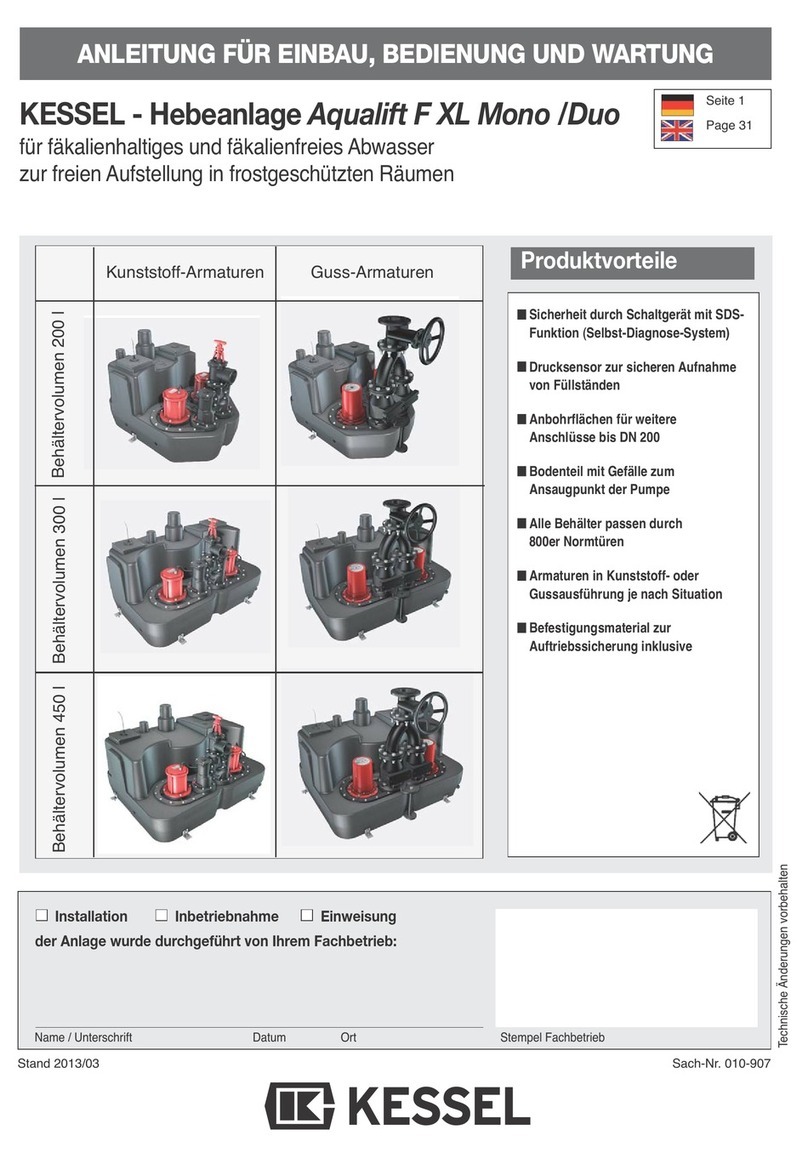

1 Introduction 34

1.1 Product description, general ............................................................................................. 34

1.2 General instructions on using these operating and maintenance instructions.................. 35

1.3 How it works...................................................................................................................... 35

1.4 Type plate ......................................................................................................................... 36

1.5 Scope of delivery .............................................................................................................. 37

1.6 Displays, operating keys and their functions .................................................................... 37

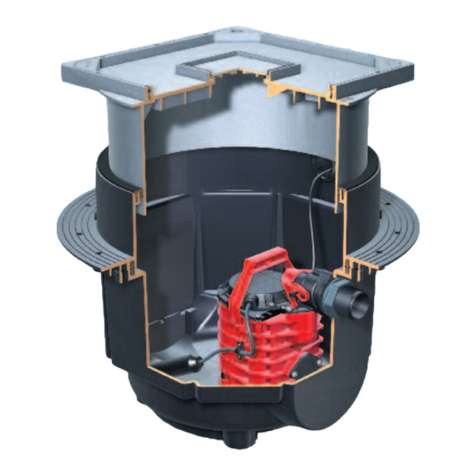

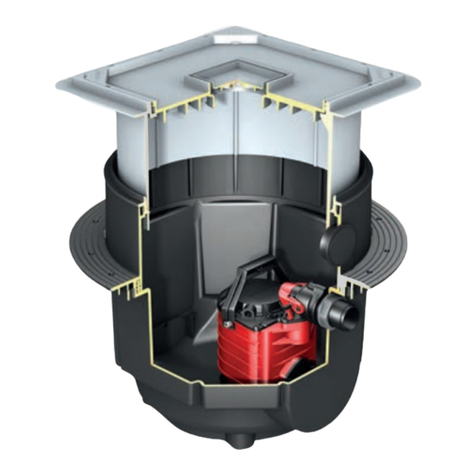

1.7 Component assemblies and functional properties............................................................ 38

2 Safety 39

2.1 Correct use ....................................................................................................................... 39

2.2 Staff selection and qualication ........................................................................................ 39

2.3 Organisational safety measures ....................................................................................... 39

2.4 Risks caused by the product............................................................................................. 40

2.4.1 Risk caused by special location / ambient conditions....................................................... 40

2.4.2 Health risks ....................................................................................................................... 40

2.4.3 Risk caused by noise........................................................................................................ 40

2.4.4 Explosion hazard .............................................................................................................. 40

2.4.5 Risk caused by heat ......................................................................................................... 40

2.4.6 Risk caused by unexpected wastewater pump start-up ................................................... 40

3 Installation 41

3.1 General points related to installation ................................................................................ 41

3.2 Fasten system tank to the oor......................................................................................... 41

3.3 Fitting the inlet and outlet.................................................................................................. 42

3.4 Connecting the ventilation pipe......................................................................................... 43

3.5 Planning a connection for manual diaphragm pump ........................................................ 43

3.6 Installing the control unit ................................................................................................... 44

3.7 Connection of a potential-free contact .............................................................................. 46

3.8 Connection of the audible alarm ....................................................................................... 46

3.9 Initial operation ................................................................................................................. 47

3.9.1 Initialising the control unit ................................................................................................. 47

3.9.2 Functional check............................................................................................................... 47

4 Operation 48

4.1 Automatic operation.......................................................................................................... 48

4.2 Alarm statuses .................................................................................................................. 48

4.2.1 System tank too full alarm ................................................................................................ 48

Table of contents