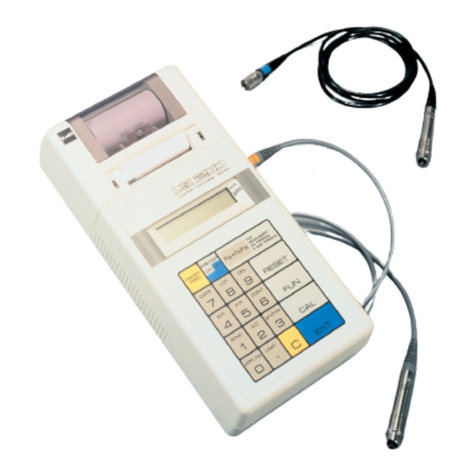

1. Universal Moisture Tester HB-300.................................................................................................................. 4

2. Features........................................................................................................................................................... 5

3. Specications.................................................................................................................................................. 6

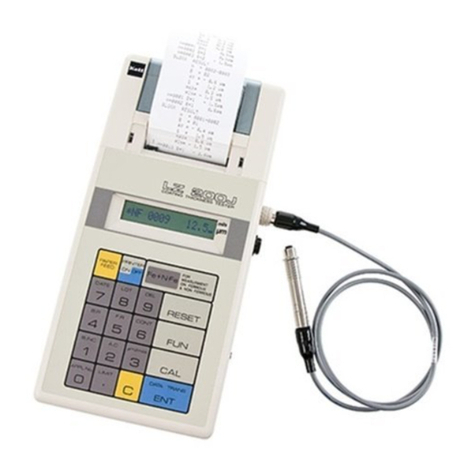

4. Nomenclature..................................................................................................................................................7

5. Display screen................................................................................................................................................. 8

6. Operation panel keys ......................................................................................................................................9

7. Flow chart for measurement ......................................................................................................................... 10

8. Preparation for measurement....................................................................................................................... 11

9. How to make the calibration ......................................................................................................................... 13

9-1. What is the calibration?....................................................................................................................... 13

9-2. How to produce the calibration curve ................................................................................................ 14

9-3. How to enter the calibration (measuring 5 samples).......................................................................... 16

9-4. How to input sample or calibration name........................................................................................... 24

10. How to measure ..........................................................................................................................................25

10-1. Measurement ..................................................................................................................................... 25

10-2. Display of the average.......................................................................................................................28

10-3. How to set continuous measurement mode...........................................................................................29

10-4. How to proceed for bias correction..................................................................................................30

10-5. How to set the alarm ......................................................................................................................... 31

10-6. Setting for printer output...................................................................................................................32

10-7. Data storage.......................................................................................................................................33

11. Function mode.............................................................................................................................................34

11-1. Display of input moisture values when preparing a calibration curve..............................................34

11-2. Erasing a calibration curve ................................................................................................................35

11-3. Printer output of stored data .............................................................................................................35

11-4. Batch erasure of stored data.............................................................................................................36

11-5. Date and time display ........................................................................................................................36

12. Error display.................................................................................................................................................39

Contents