IMPORTANT

MACHINE CALIBRATIONS

DO NOT CALIBRATE THE JAWS. The Ninja Laser is manufactured to highly precise specifications.

Machines and consoles are uniquely paired on initial factory setup. All cutter and jaw calibrations have

been performed at the factory matching the jaw to the machine thus making calibrations by the user

unnecessary. Consoles and machines cannot be swapped with different versions without consenting

Keyline technical team for instructions.

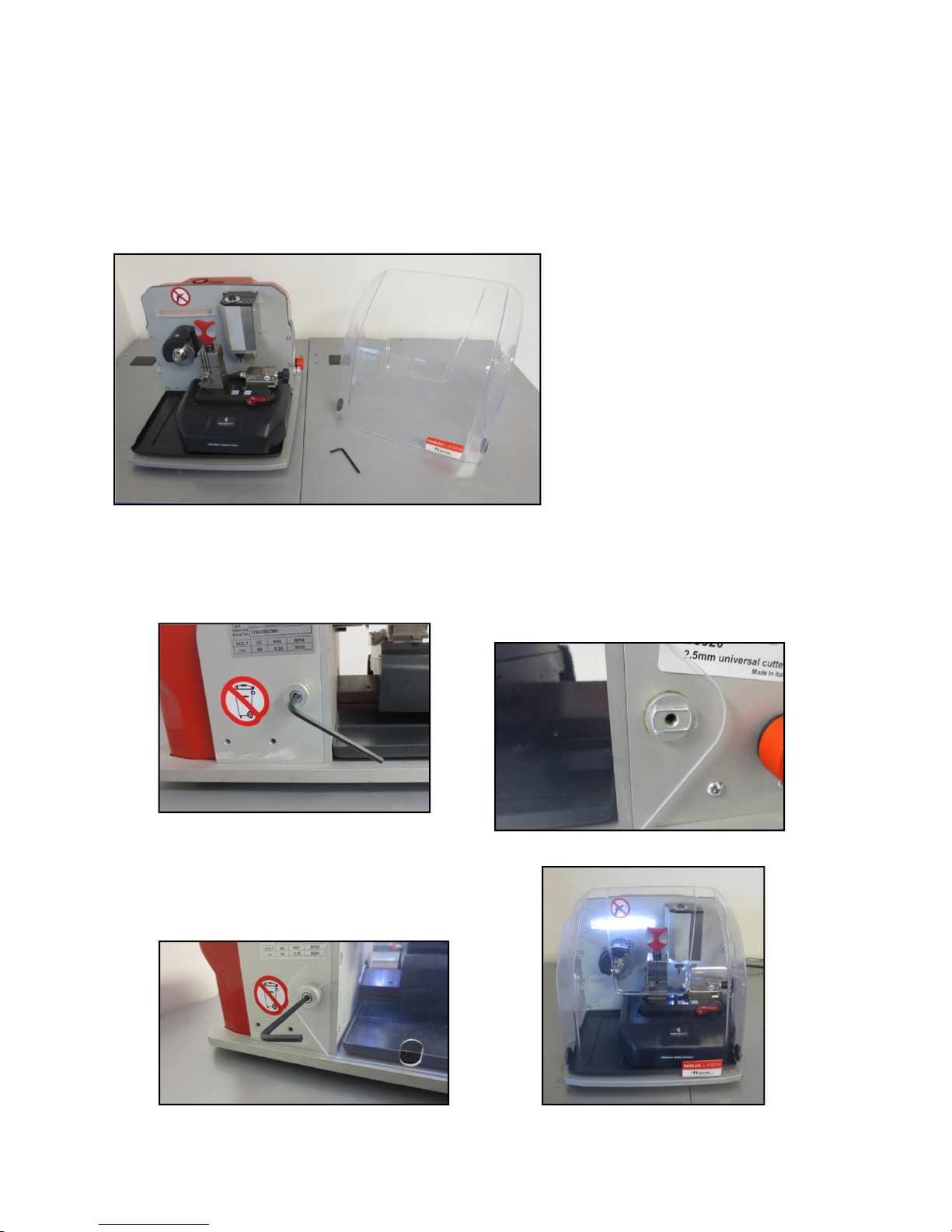

SAFETY SHIELD

The safety shield works in conjunction with the software prompts. The software, before starting some

cut and decode procedures, requires the closing of the safety shield. If it is not closed when requested,

it will continue to ask its closing. If the user opens the safety shield during an operating phase (for

example, when the machine is cutting or decoding a key) it will stop immediately and, at the closing of

the shield, the machine will reset the operation and go back to the beginning of the procedure. Make

sure to complete all parts of the process (i.e. positioning AC jaw in correct position, securing key on

jaw, removing tip stop, etc) at one time, then close the shield before proceeding to the next step. This

will avoid having to replicate steps.

KEY MATERIAL

The Ninja Laser defaults to cutting brass keys as the key material type. If you are cutting a different

type of metal key, such as steel, nickel silver or aluminum, you can make the selection in the cutting

screen. Please note the Ninja Laser cannot cut or decode any type of plastic key, painted keys or keys

made of non-conductive materials.

USE OF AFTERMARKET SPARE PARTS

Keyline machines require the use of factory original parts. Aftermarket cutters, tracers and adaptors

are not recommended and may cause product damage that will void your machine warranty.

MACHINE PACKAGING

Please retain all machine packaging for transportation purposes. Packaging is specially designed to

safely transport the machine and it’s components. Keyline is not responsible for providing additional

packing material if original boxes are lost, damaged or discarded.

WARRANTY INFORMATION

In Warranty (within 90 days of purchase): Customer will return machine and Keyline USA will the

reimburse shipping charges. Keyline USA will pay the return shipping back to the customer

In Warranty (91+ days of purchase): Customer will pay to return the machine to Keyline USA.

Keyline USA will pay the return shipping back to the customer

Out of Warranty: Customer will pay to return the machine to Keyline USA. Customer will pay the

return shipping back to the customer

TEMPERATURE

Machine operating temperature is between 32 and 104 degrees Fahrenheit.

5

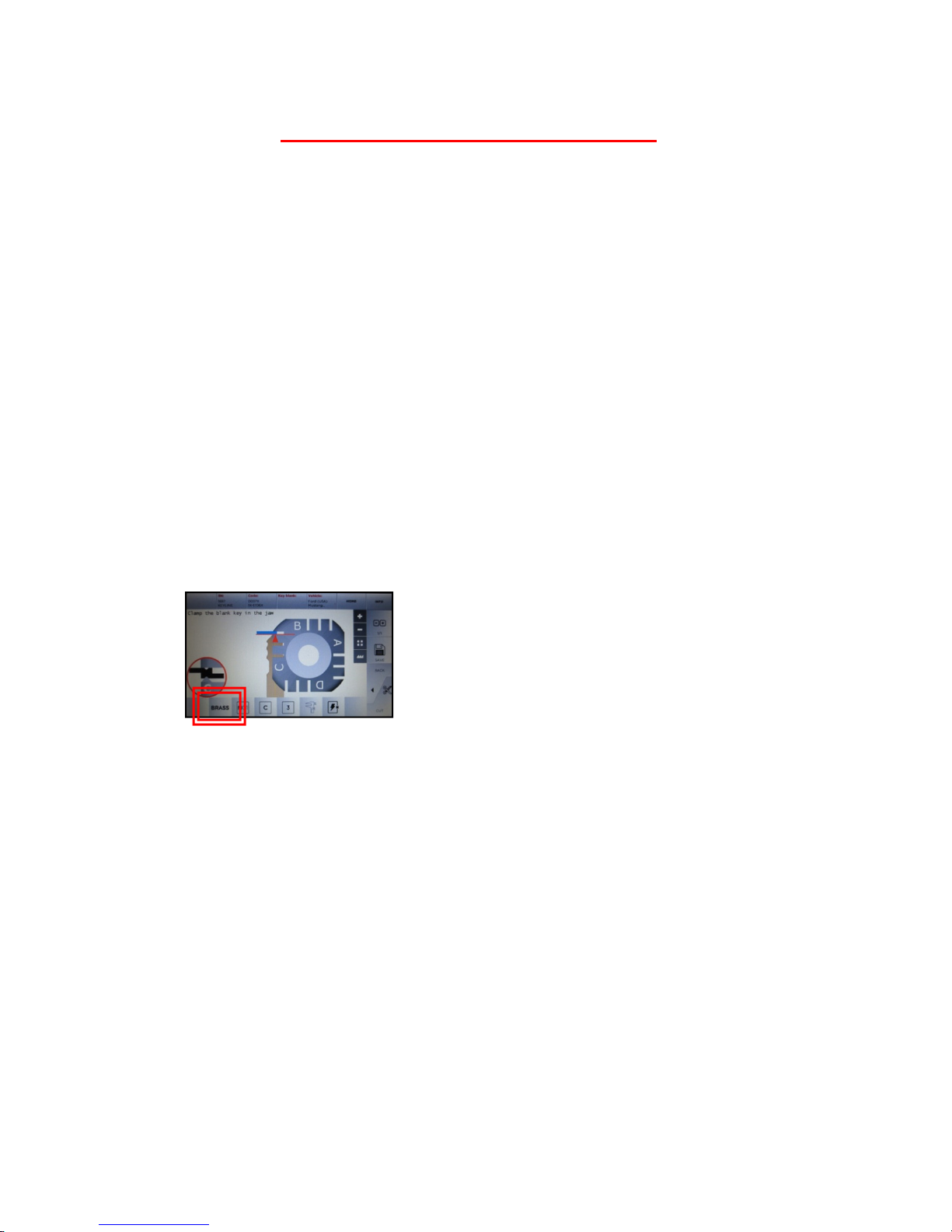

To change the material type, simply touch the

BRASS icon on the screen until you reach the

desired material; BRASS, STEEL, NiSi (Nickel

Silver) or ALU (aluminum)