2 Keysight 86205A Operating and Service Manual

Notices

Copyright Notice

© Keysight Technologies 1992 - 2019

No part of this manual may be reproduced in

any form or by any means (including electronic

storage and retrieval or translation into a for-

eign language) without prior agreement and

written consent from Keysight Technologies as

governed by United States and international

copyright laws.

Manual Part Number

86205-90001

Edition

Edition 2, March 12, 2019

Printed in:

Printed in Malaysia

Published by:

Keysight Technologies

Bayan Lepas Free Industrial Zone,

11900 Penang, Malaysia

Technology Licenses

The hardware and/or software described in

this document are furnished under a license

and may be used or copied only in accordance

with the terms of such license.

Declaration of Conformity

Declarations of Conformity for this product

and for other Keysight products may be down-

loaded from the Web. Go to http://www.key-

sight.com/go/conformity. You can then search

by product number to find the latest Declara-

tion of Conformity.

U.S. Government Rights

The Software is “commercial computer soft-

ware,” as defined by Federal Acquisition Regu-

lation (“FAR”) 2.101. Pursuant to FAR 12.212

and 27.405-3 and Department of Defense FAR

Supplement (“DFARS”) 227.7202, the U.S.

government acquires commercial computer

software under the same terms by which the

software is customarily provided to the public.

Accordingly, Keysight provides the Software to

U.S. government customers under its standard

commercial license, which is embodied in its

End User License Agreement (EULA), a copy of

which can be found at http://www.key-

sight.com/find/sweula. The license set forth in

the EULA represents the exclusive authority by

which the U.S. government may use, modify,

distribute, or disclose the Software. The EULA

and the license set forth therein, does not

require or permit, among other things, that

Keysight: (1) Furnish technical information

related to commercial computer software or

commercial computer software documenta-

tion that is not customarily provided to the

public; or (2) Relinquish to, or otherwise pro-

vide, the government rights in excess of these

rights customarily provided to the public to

use, modify, reproduce, release, perform, dis-

play, or disclose commercial computer soft-

ware or commercial computer software

documentation. No additional government

requirements beyond those set forth in the

EULA shall apply, except to the extent that

those terms, rights, or licenses are explicitly

required from all providers of commercial com-

puter software pursuant to the FAR and the

DFARS and are set forth specifically in writing

elsewhere in the EULA. Keysight shall be

under no obligation to update, revise or other-

wise modify the Software. With respect to any

technical data as defined by FAR 2.101, pursu-

ant to FAR 12.211 and 27.404.2 and DFARS

227.7102, the U.S. government acquires no

greater than Limited Rights as defined in FAR

27.401 or DFAR 227.7103-5 (c), as applicable

in any technical data.

Warranty

THE MATERIAL CONTAINED IN THIS DOCU-

MENT IS PROVIDED “AS IS,” AND IS SUBJECT

TO BEING CHANGED, WITHOUT NOTICE, IN

FUTURE EDITIONS. FURTHER, TO THE MAXI-

MUM EXTENT PERMITTED BY APPLICABLE

LAW, KEYSIGHT DISCLAIMS ALL WARRAN-

TIES, EITHER EXPRESS OR IMPLIED, WITH

REGARD TO THIS MANUAL AND ANY INFOR-

MATION CONTAINED HEREIN, INCLUDING

BUT NOT LIMITED TO THE IMPLIED WARRAN-

TIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE. KEYSIGHT

SHALL NOT BE LIABLE FOR ERRORS OR FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES

IN CONNECTION WITH THE FURNISHING,

USE, OR PERFORMANCE OF THIS DOCU-

MENT OR OF ANY INFORMATION CONTAINED

HEREIN. SHOULD KEYSIGHT AND THE USER

HAVE A SEPARATE WRITTEN AGREEMENT

WITH WARRANTY TERMS COVERING THE

MATERIAL IN THIS DOCUMENT THAT CON-

FLICT WITH THESE TERMS, THE WARRANTY

TERMS IN THE SEPARATE AGREEMENT

SHALL CONTROL.

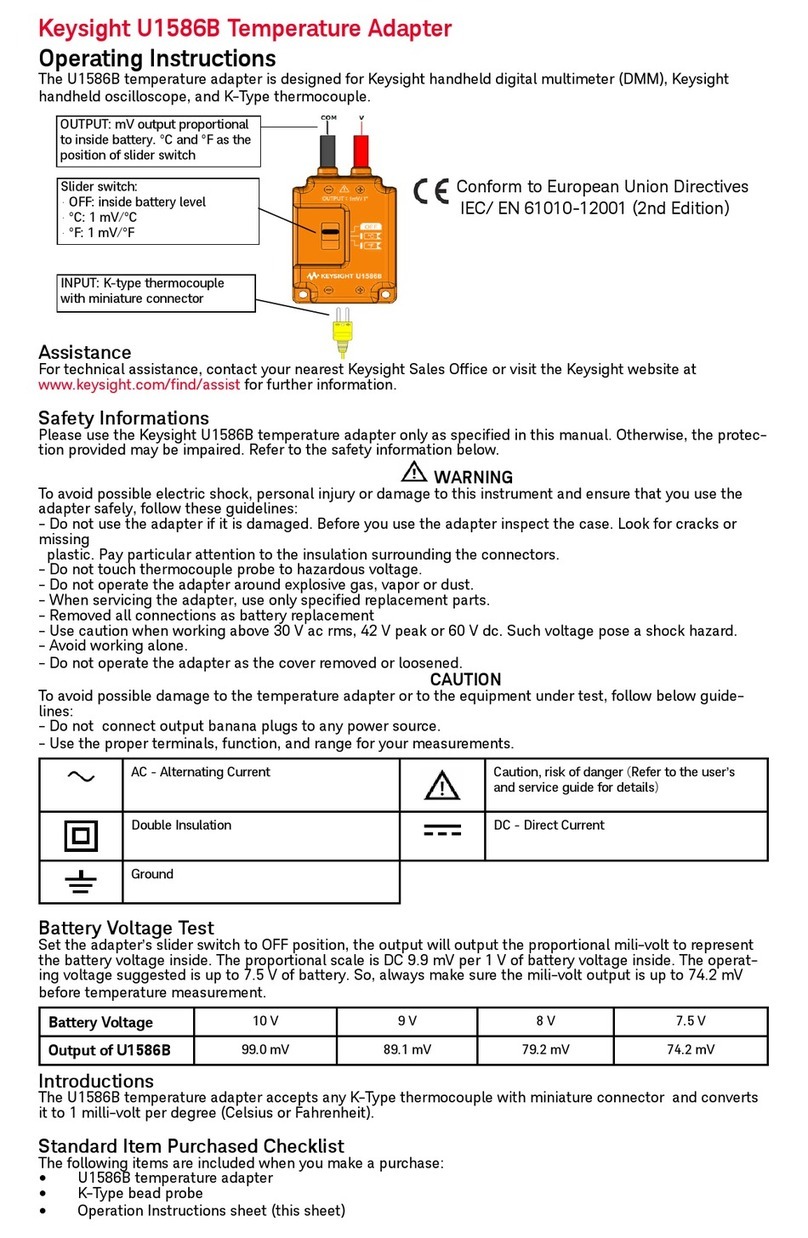

Safety Information

A CAUTION notice denotes a hazard. It calls

attention to an operating procedure, practice,

or the like that, if not correctly performed or

adhered to, could result in damage to the

product or loss of important data. Do not pro-

ceed beyond a CAUTION notice until the indi-

cated conditions are fully understood and met.

A WARNING notice denotes a hazard. It calls

attention to an operating procedure, practice,

or the like that, if not correctly performed or

adhered to, could result in personal injury or

death. Do not proceed beyond a WARNING

notice until the indicated conditions are fully

understood and met.