Xsede® 3

Part 3095953, Revision -

Assembly Instructions

Proper product installation, in accordance with these instructions, is the responsibility of the installing agent. If you have

any questions concerning these instructions, please call Kimball Customer Care.

Xsede Privacy Screens

Tools Required

• Box Cutter/Utility Knife

• Cordless Drill w/#2 Phillips head bit drive

Hardware Required

1 - Privacy Screen

2 - Privacy Screen Brackets

8 - 1/4-20 X 3/4” Pan Head Phillips Wood Screws

2 - 1/4-20 X 1/2” Pan Head Phillips Machine Screws (used for

screen alignment)

8 - Screen Spacers 1/4” Thick

Installation

Note: Privacy Screens should be installed after bases/tops.

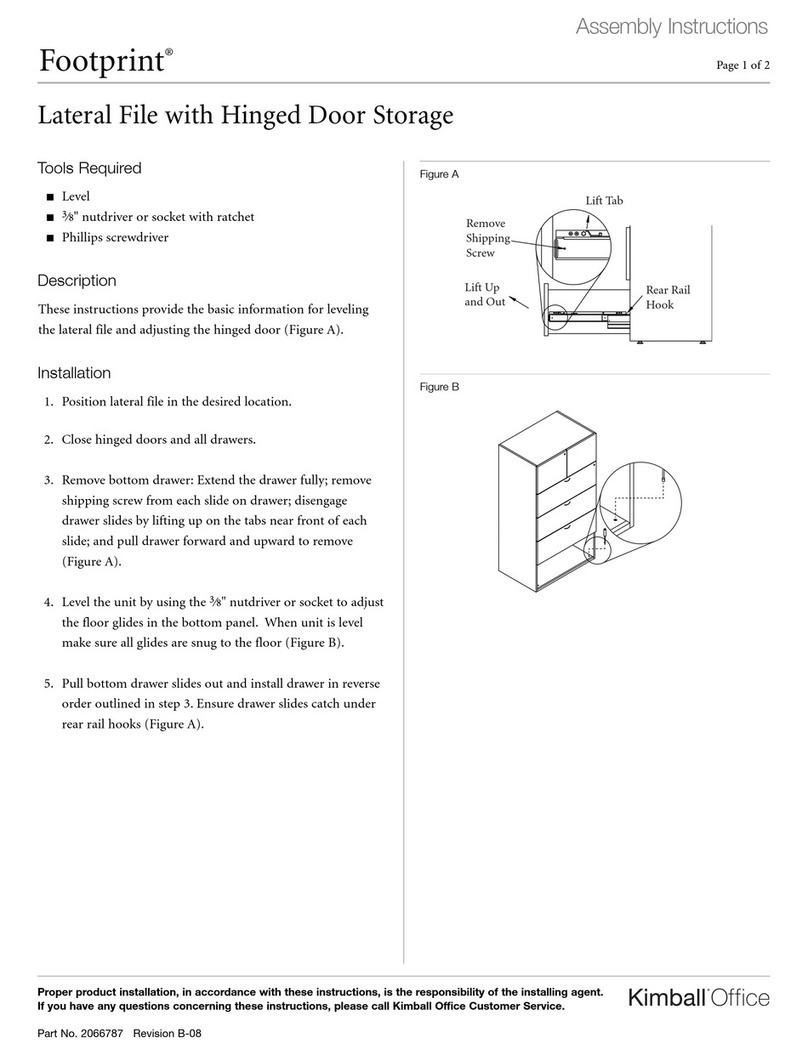

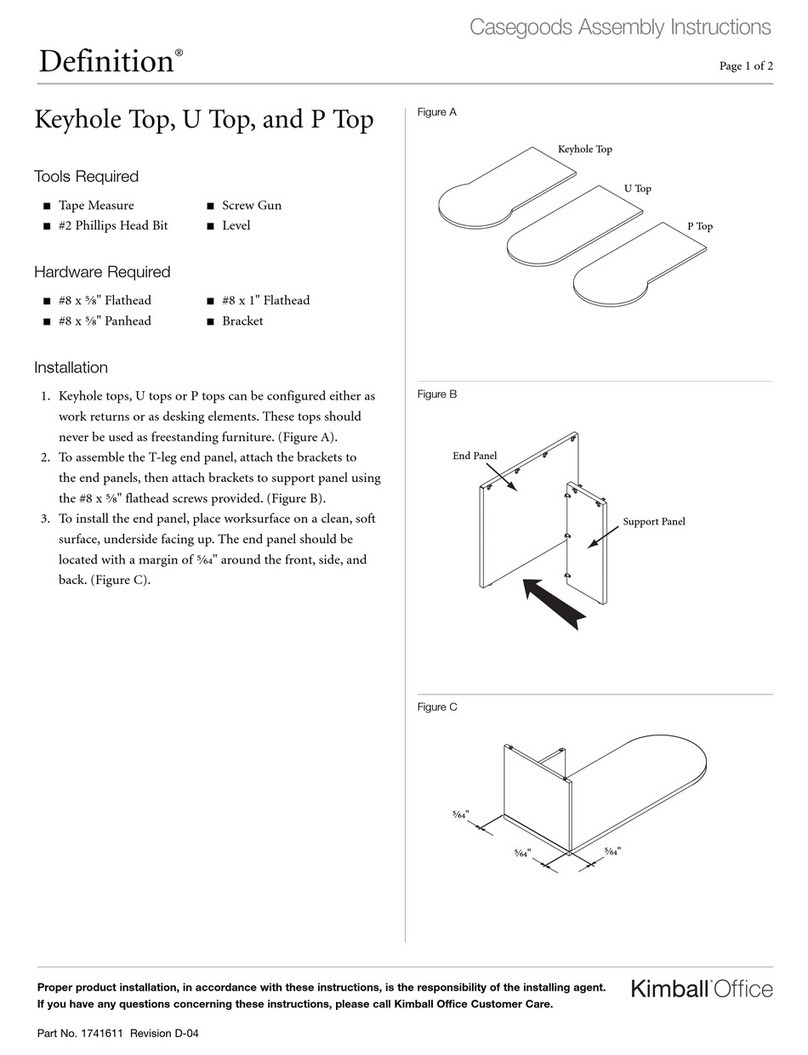

1. Using a knife, open box removing screen, brackets, and

parts bag. See Figure A.

2. Lay screen on a non-marring surface for assembly.

3. Slide screen spacers over threaded inserts. Place screen

brackets over (4) holes positioning as such shown in Fig-

ure B. Attach using drill w/#2 Phillips drive 1/4-20 X 3/4”

machine screws through spacers into inserts. Note: Don’t

over tighten or threaded inserts might pull out of core.

4. When assembling screen to L-base or Single base, there is a

range to mount screen either flush to top - or maximum 1”

wire gap. This is to ensure table stability. Don’t exceed

1” gap between surface and screen. See Figure D for

mounting options.

5. When attaching screens to bench base, there *MUST* be a

1” gap in between screens for prevention of pinched fingers

when screens raise and lower. See Figure D.

6. To attach privacy screens, the edge of screen and edge of

work surface will set flush to each other as shown in Fig-

ure C, left picture. For screen attachments, using drill w/

#2 Phillips drive, attach all #8 X 3/4” wood screws, 4 for

each bracket to worksurface.

Figure A

Figure B

Figure C