Table of contents

1. Introduction....................................................................................................................................................................... 4

1.1. Key points................................................................................................................................................................. 4

1.2. Technical features..................................................................................................................................................... 4

1.3. General technical features........................................................................................................................................ 5

2. Presentation of airflow meter............................................................................................................................................ 6

2.1. ase.......................................................................................................................................................................... 6

2.2. Grid........................................................................................................................................................................... 7

2.3. Electronic housing..................................................................................................................................................... 7

Features:......................................................................................................................................................................... 7

2.3.1. Airflow meter mode........................................................................................................................................... 8

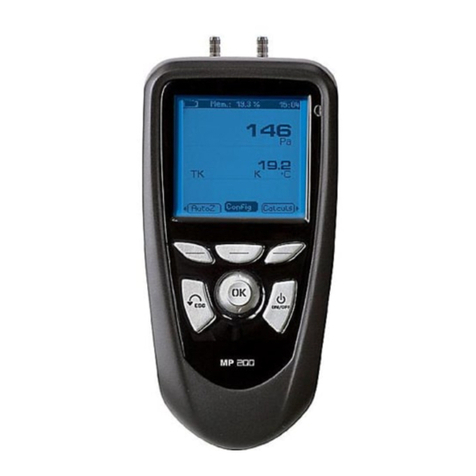

2.3.2. Micromanometer mode..................................................................................................................................... 8

2.3.3. Power supply of electronic housing................................................................................................................... 8

2.4. Hoods........................................................................................................................................................................ 9

3. Mounting the airflow meter................................................................................................................................................ 9

3.1. Mounting of frame..................................................................................................................................................... 9

3.2. Setting of the cloth.................................................................................................................................................. 10

3.3. Setting of rods......................................................................................................................................................... 11

4. Using D M610 in airflow meter mode............................................................................................................................. 12

4.1. Starting up............................................................................................................................................................... 12

4.2. Configure the airflow meter..................................................................................................................................... 12

4.2.1. Set the correction coefficient........................................................................................................................... 12

4.2.2. Set measurement units................................................................................................................................... 12

4.2.3. Set a damping................................................................................................................................................. 12

4.2.4. Activate or deactivate standardised airflow..................................................................................................... 12

4.3. Perform averages.................................................................................................................................................... 13

4.3.1. Perform an automatic average........................................................................................................................ 13

4.3.2. Perform an aggregate of automatic averages................................................................................................. 13

5. Using D M610 in micromanometer mode...................................................................................................................... 14

5.1. Starting up............................................................................................................................................................... 14

5.2. Set the micromanometer......................................................................................................................................... 14

5.2.1. Select the airflow sensor................................................................................................................................. 14

5.2.2. Set the surface................................................................................................................................................ 14

5.2.3. Set measurement units................................................................................................................................... 15

5.2.4. Set a damping................................................................................................................................................. 15

5.2.5. Activate or deactivate the solenoid valve........................................................................................................ 15

5.2.6. Set the thermocouple type.............................................................................................................................. 15

5.2.7. Set the compensation temperature................................................................................................................. 16

5.2.8. Activate or deactivate the standardised airflow............................................................................................... 16

5.3. Activate or deactivate air velocity and airflow.......................................................................................................... 16

5.4. Use the Matrix grid.................................................................................................................................................. 16

5.5. Perform averages.................................................................................................................................................... 16

5.5.1. Automatic average.......................................................................................................................................... 16

5.5.2. Point/point average......................................................................................................................................... 16

5.5.3. Point/point automatic average......................................................................................................................... 17

5.6. Perform an autozero............................................................................................................................................... 17

5.7. Hold the measurement............................................................................................................................................ 17

6. Manage dataset recordings............................................................................................................................................. 18

6.1. Get to recorded datasets......................................................................................................................................... 18

6.2. Delete recorded datasets........................................................................................................................................ 18

7. Set the device................................................................................................................................................................. 19

7.1. Set date and time.................................................................................................................................................... 19

7.2. Set language........................................................................................................................................................... 19

7.3. Set automatic shut-off............................................................................................................................................. 19

7.4. Set brightness......................................................................................................................................................... 19

7.5. Set contrast............................................................................................................................................................. 19

7.6. Activate or deactivate beep..................................................................................................................................... 19

8. Information about the device........................................................................................................................................... 20

8.1. Identification............................................................................................................................................................ 20

8.2. Calibration............................................................................................................................................................... 20

8.3. After sales service................................................................................................................................................... 20