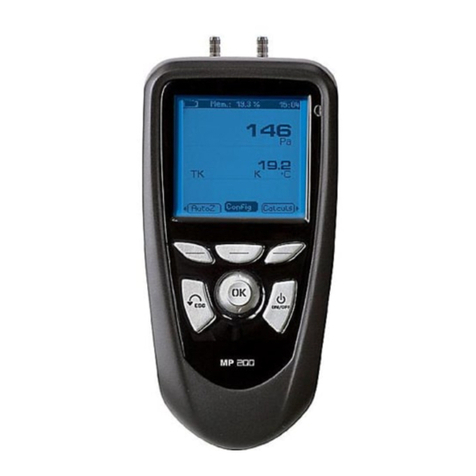

DP500

Table of Contents

1 SAFETY INSTRUCTIONS......................................................................................................................................5

2 APPLICATION AREA..............................................................................................................................................6

3 TECHNICAL DATA..................................................................................................................................................7

4 INSTALLATION AND MEASUREMENTS...............................................................................................................8

4.1 Measu ement with measu ing chambe , connection via plug nipple....................................................................................8

4.2 Measu ement without measu ing chambe , connection via exte nal th ead G1/2’’...............................................................8

4.3 Dew point measu ing at synthetic g anules -d ies................................................................................................................ 9

5 MAINTENANCE......................................................................................................................................................9

6 CALIBRATION/ ADJUSTMENT..............................................................................................................................9

7 CABLE CROSS SECTION.....................................................................................................................................9

7.1 Senso ci cuit points/Output signal:...................................................................................................................................... 9

8 DP 500 OPERATION............................................................................................................................................10

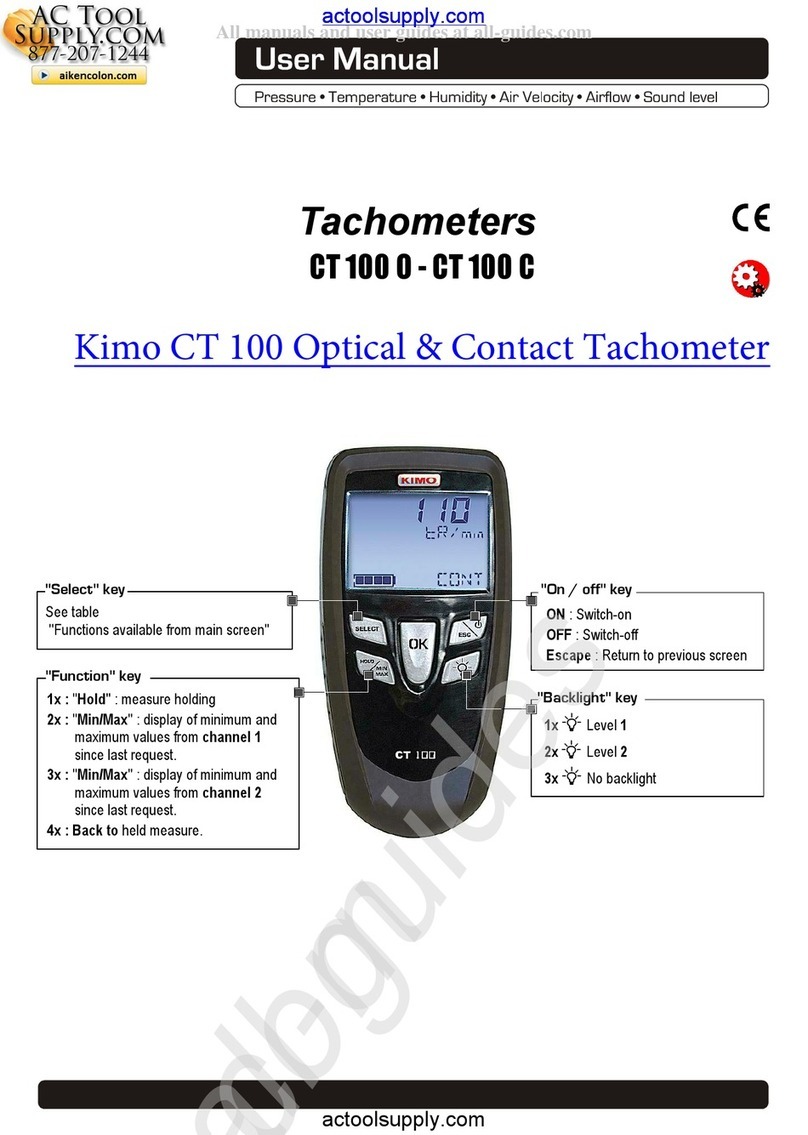

8.1 Keypad............................................................................................................................................................................... 10

8.1.1 On andOff button........................................................................................................................................................ 10

8.1.2 B ightness buttons...................................................................................................................................................... 10

8.1.3 Sc eenshot-Button...................................................................................................................................................... 10

8.1.3.1 Sto ing Sc eenshot................................................................................................................................................................ 10

8.1.3.2 Expo t Sc eenshots................................................................................................................................................................ 11

8.2 Touchpanel......................................................................................................................................................................... 12

8.3 Main menu (Home)............................................................................................................................................................ 13

8.3.1 Initialization................................................................................................................................................................. 13

8.3.2 Main menu.................................................................................................................................................................. 14

8.3.2.1 Settings.................................................................................................................................................................................. 15

8.3.2.1.1 Passwo d-Settings......................................................................................................................................................... 15

8.3.2.1.2 Senso -settings.............................................................................................................................................................. 16

8.3.2.1.2.1 Settings inte nal Dewpoint-Senso .......................................................................................................................... 17

8.3.2.1.2.1.1 Definition of the System p essu e ( elative p essu e value).............................................................................17

8.3.2.1.2.1.2 Definition of Refe ence p essu e (absolute p essu e value)............................................................................ 18

8.3.2.1.2.2 Choice of the senso type....................................................................................................................................... 18

8.3.2.1.2.3 Name the measu ement data and define the decimal places.................................................................................. 20

8.3.2.1.2.4 Reco ding measu ementdata.................................................................................................................................. 21

8.3.2.1.2.5 Ala m-Settings ( Ala m Popup)................................................................................................................................ 21

8.3.2.1.2.6 Mo e Settings (scale analogue output)................................................................................................................... 22

8.3.2.1.2.7 Dew Point Senso of type CS-Digital...................................................................................................................... 24

8.3.2.1.2.8 Label and setting the desc iption fields................................................................................................................... 24

8.3.2.1.2.9 Type 0 - 1/10/30 Volt and 0/4 – 20 mA.................................................................................................................... 27

8.3.2.1.2.10 Type PT100x and KTY81...................................................................................................................................... 29

8.3.2.1.2.11 Type Pulse (Pulse ation)...................................................................................................................................... 30

8.3.2.1.2.12 Type„No Senso “.................................................................................................................................................. 31

8.3.2.1.3 Data logge Settings....................................................................................................................................................... 33

8.3.2.1.4 Device Settings.............................................................................................................................................................. 37

8.3.2.1.4.1 Language............................................................................................................................................................... 37

8.3.2.1.4.2 Date &Time............................................................................................................................................................ 37

8.3.2.1.4.3 SD-Ca d................................................................................................................................................................. 38

8.3.2.1.4.4 System update....................................................................................................................................................... 38

8.3.2.1.4.4.1 Save System Settings..................................................................................................................................... 39

8.3.2.1.4.4.2 Check fo new Softwa e updates (USB).......................................................................................................... 39

8.3.2.1.4.4.3 Resto e System Settings................................................................................................................................. 40

8.3.2.1.4.5 Facto y Reset......................................................................................................................................................... 41

8.3.2.1.4.6 Calib ate touch-sc een............................................................................................................................................ 42

8.3.2.1.5 Set backlight.................................................................................................................................................................. 42

8.3.2.1.6 Cleaning......................................................................................................................................................................... 43

8.3.2.1.7 System-Status................................................................................................................................................................ 43

8.3.2.1.8 About DP 500................................................................................................................................................................. 43

8.3.2.2 Cha t...................................................................................................................................................................................... 44

8.3.2.3 Cha t / Real time values......................................................................................................................................................... 47

8.3.2.4 Channels............................................................................................................................................................................... 49

8.3.2.4.1 Min/Max Function........................................................................................................................................................... 49

8.3.2.5 Real time values.................................................................................................................................................................... 50

3