VEB-46/VEP-43 Series 3-Way, NPT, Control Ball Valves (1⁄2 to 21⁄2") 2 Installation Guide© 2016 KMC Controls, Inc. 050-019-51H

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com

For additional instructions on wiring, feedback selec-

tor, and actuator/signal range reset (auto-mapping),

see the MEP-4000/4800 Series Installation Guide or

(fail-safe) MEP-4200/4500/4900 Series Installation

Guide.

More Information

For non-fail-safe wiring,

auxiliary switches, feed-

back/direction selectors,

actuator/signal range reset

(auto-mapping), and other

information, see the MEP-

4000/4800 Series Installa-

tion Guide.

Formodels,specications,

and additional information,

see the VEB-46/VFB-46

Series Data Sheet on the

KMC web site.

CLWiring (MEP-4x52)

For information on assem-

bling a quick-mount “V”

actuator on a valve body, see

the HPO-5074 Installation

Guide.

For fail-safe wiring,

auxiliary switches, feed-

back/direction selectors,

actuator/signal range

reset (auto-mapping), and

other information, see the

MEP-4200/4500/4900 Series

Installation Guide.

Wiring

NOTE: The installed actuator model is indicated

by the last two digits of the VEB valve

model number (e.g., VEB-46xxxxCK

has an MEP-4002V actuator) and the

last three digits of the older VEP valve

model number (e.g., VEP-43xxx745 has an

MEP-4002 actuator). For wiring and other

information about tri-state and other

actuators no longer sold mounted on

these valves, see the respective actuator’s

installation guide on the KMC web site.

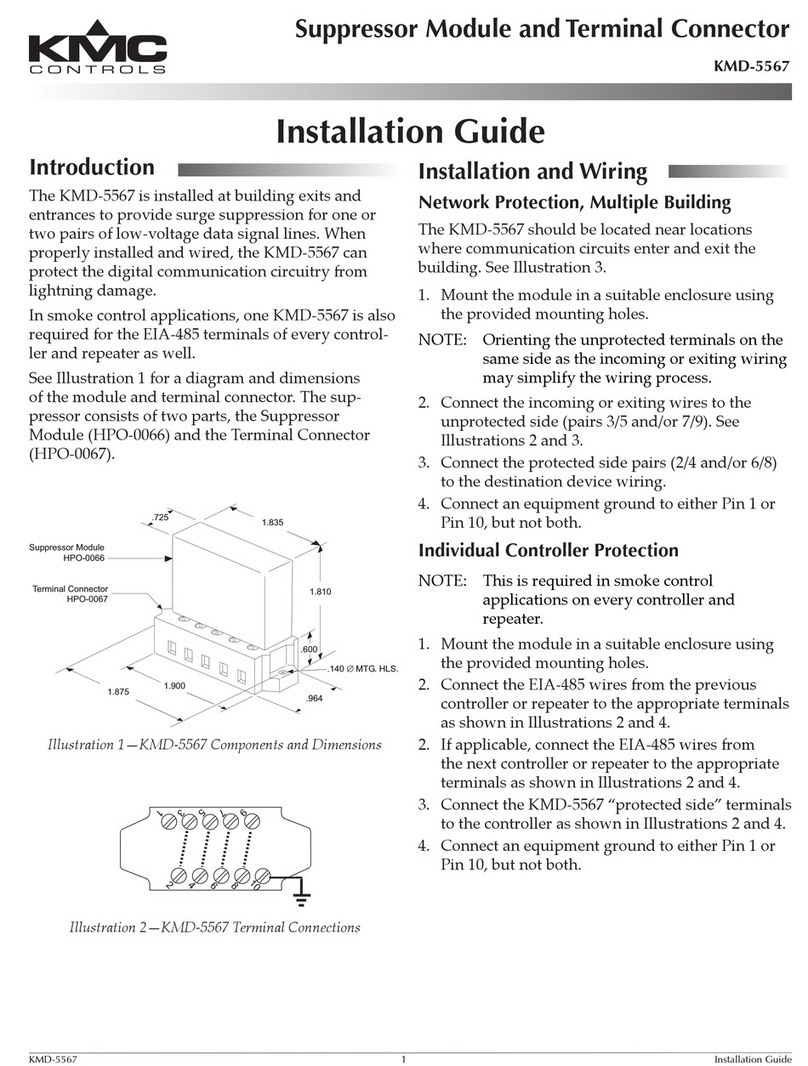

CK/745Wiring (MEP-4002)

Power

Supply

~

–

–

+

Control Signal:

0–10 or

2–10VDC

–

+Feedback Output:

1–5 or 2–10VDC

(with 2–10VDC Input)

or 0–5 or 0–10VDC

(with 0–10VDC Input)

–

–

–

~/+

+

Control Signal

2–10VDC

or 0–10VDC

Power Supply

24VAC/VDC

OUT (Green)

INPUT (White)

T

COM (Black)

~24V (Red)

+

Feedback Output

1–5 or 2–10VDC

or

0–5 or 0–10VDC