Product specications ........................................................ 1

Preface ............................................................................... 1

General safety rules for woodworking machinery............... 1

Additional safety rules for table saws ................................ 2

Assembly instruction .......................................................... 2

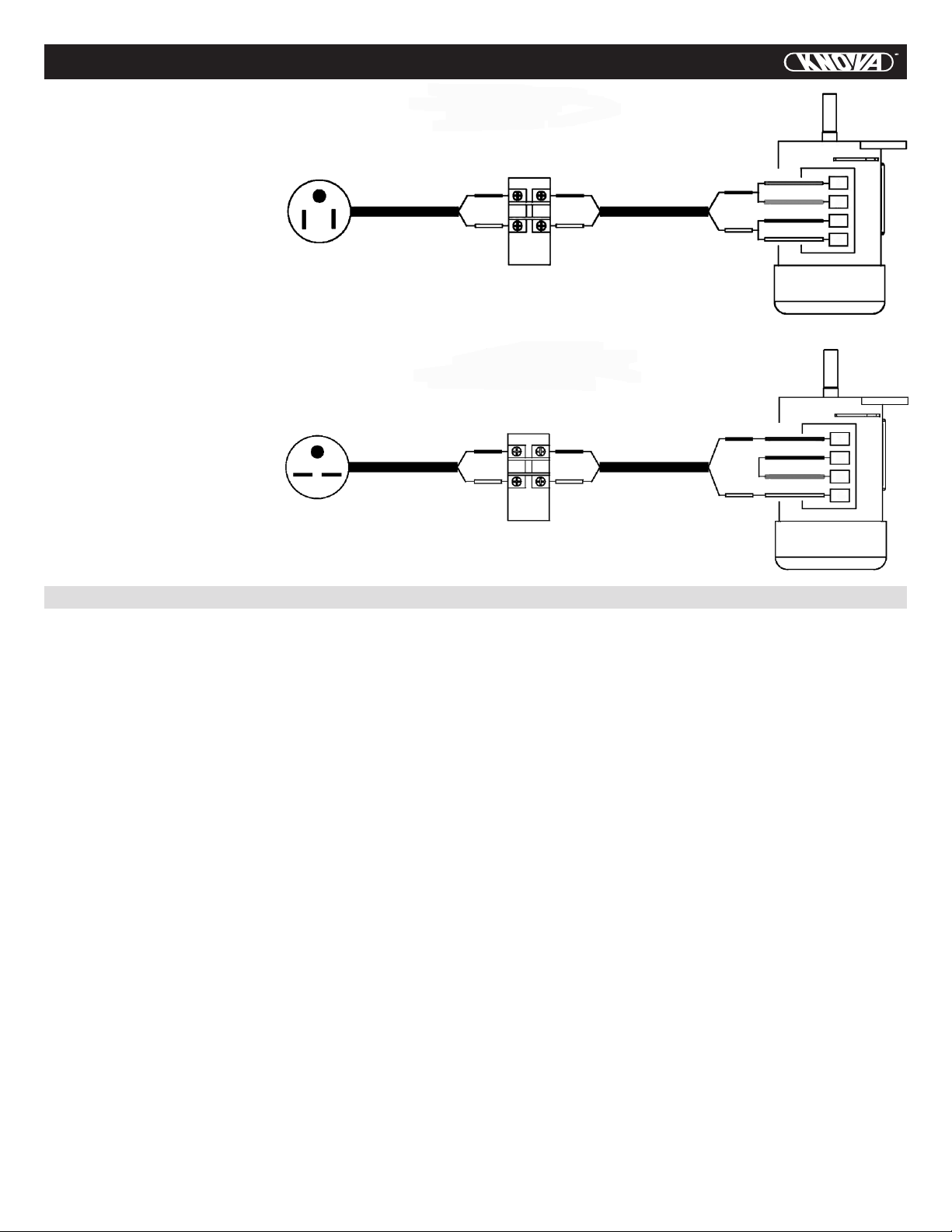

Electrical ............................................................................ 3

Wiring diagrams ................................................................. 4

Glossary of terms for woodworking ................................... 4

Know you machine ............................................................ 5

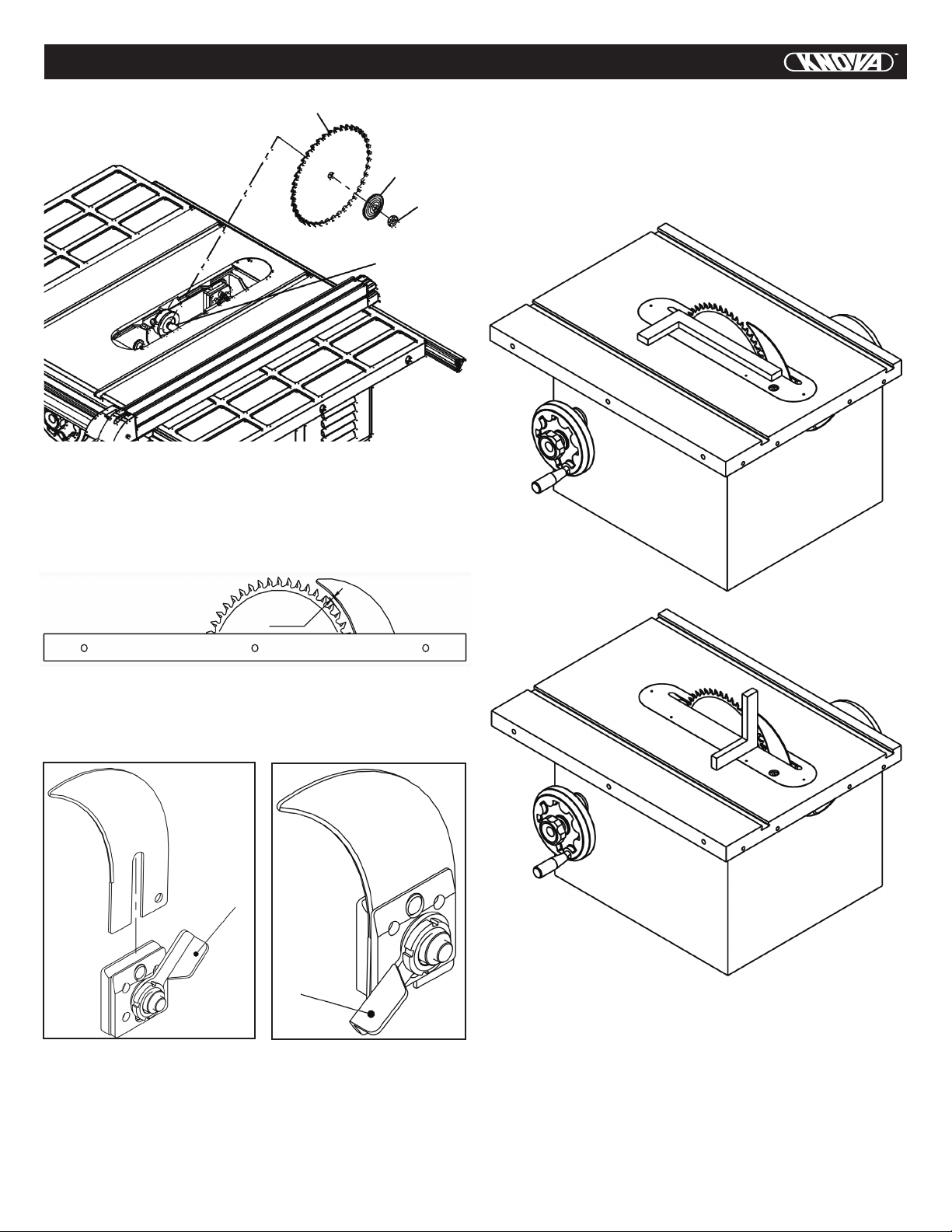

Assemble and adjustments ................................................ 6

Adjusting the miter gauge .................................................. 11

Assembly diagram stand .................................................... 12

Assembly diagram motor ................................................... 13

Part list of stand and motor ............................................... 14

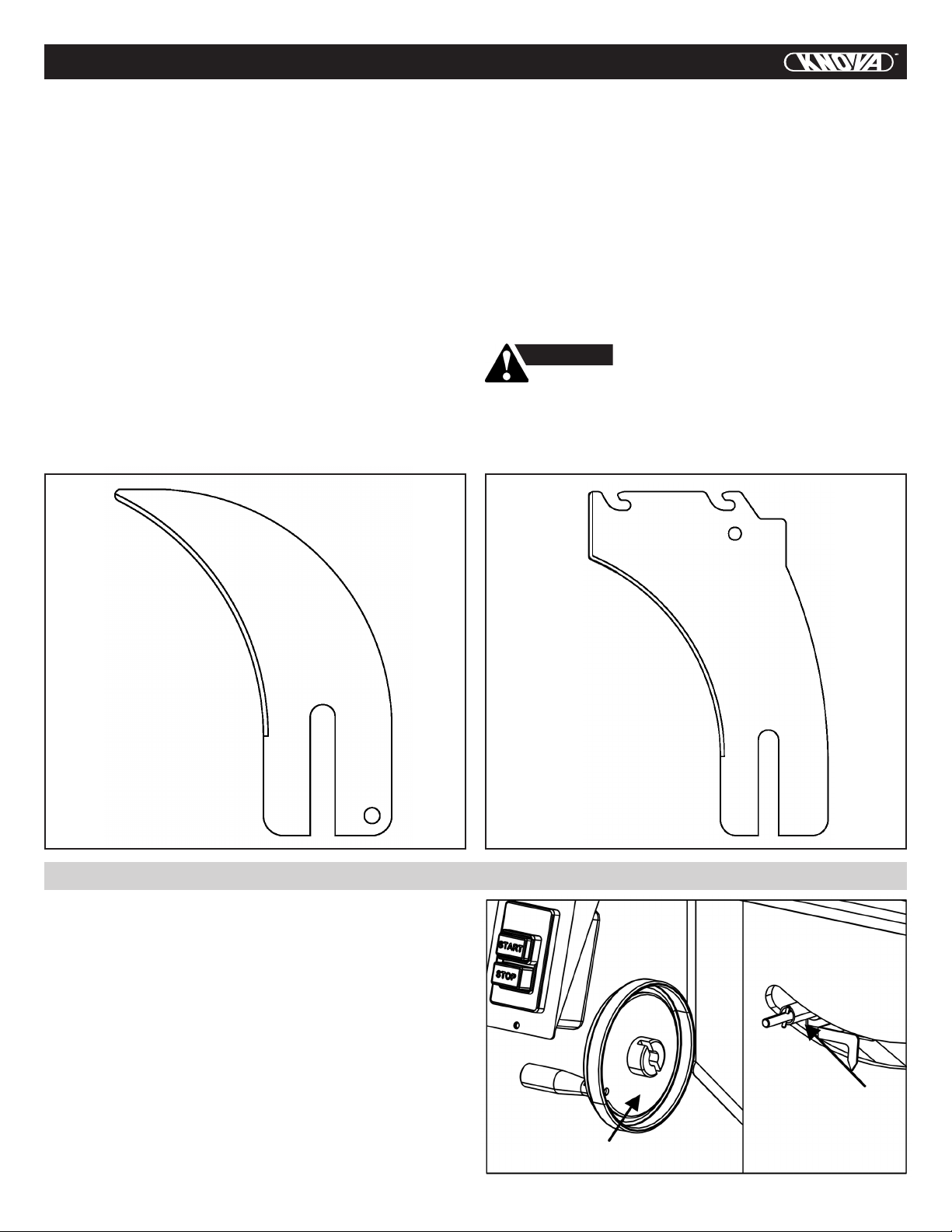

Assembly diagram blade cover .......................................... 16

Assembly diagram miter gauga .......................................... 16

Part list of blade cover and miter gauge ............................ 17

Assembly diagram of the base .......................................... 18

Assembly diagram of the table .......................................... 19

Part list of base and table .................................................. 19

PRODUCT SPECIFICATIONS

Motor:

1-1/2 H.P. 120/240 V. 60 Hz.

Idle speed: 3,450 RPM.

Arbor size: 5/8” (15.8 mm)

Saw blade: 10” (254 mm)

TABLE OF CONTENTS

1

PREFACE

Thank you for choosing this tilting arbor table saw. We are pleased to offer you our best machinery and service, and trust that you will nd

our machinery economical, productive and easy to operate.

This manual covers the proper operation, safety and maintenance of the machine. It is important that this manual be read in its entirety

before operating the machine. Although the machine has been checked and inspected in compliance with relevant safety regulations, the

machine’s safety and best performance are dependent on proper maintenance and operation. Hazards that arise due to improper operation

and maintenance are solely the responsibility of the operator.

We thank you again for you choice, and for your careful reading of this manual.

GENERAL SAFETY RULES FOR WOODWORKING MACHINERY

There is a certain amount of hazard involved with the use of woodworking machinery. Using the machine with the respect and

caution demanded as far as safety precautions are concerned will considerably lessen the possibility of personal injury.

However, if normal safety precautions are overlooked or ignored, several personal injury to the operator can occur. If you have

any questions relative to its application DO NOT use the tool until you have read what we have advised you.

1. KNOW YOUR POWER TOOL. Read the owner’s manual

carefully. Learn the tools applications and limitations,

as well as the specic potential hazards peculiar to it.

2. KEEP GUARDS IN PLACE and in working order.

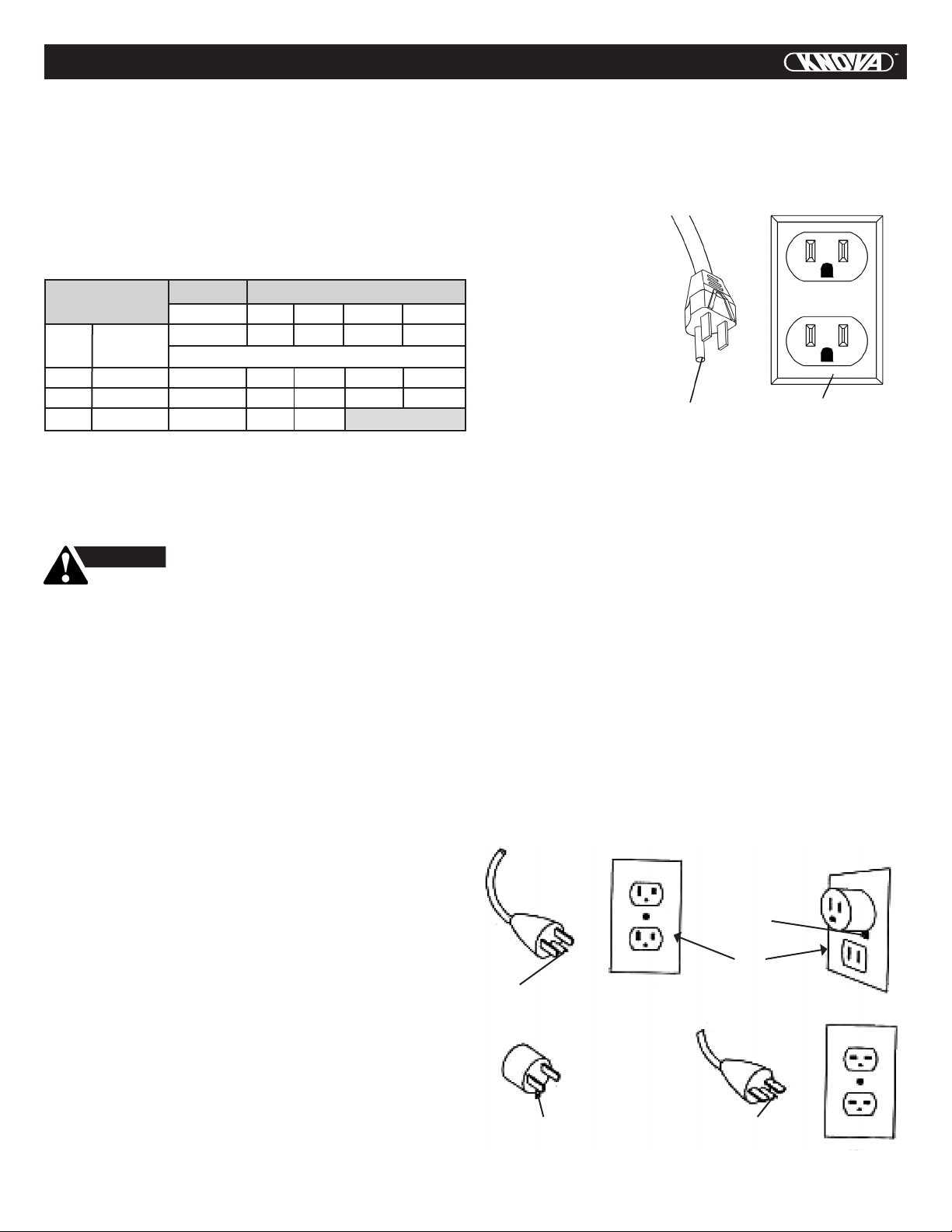

3. GROUND ALL TOOLS. If tool is equipped with

three-prong plug. It should be plugged into a three-pole

electrical receptacle. If an adapter is used to

accommodate a two-prong receptacle, the adapter lug

must be attached to known ground. Never remove

the third prong.

4. REMOVE ADJUSTING KEYS AND WRENCHES. Form

habit of checking, to see that keys and adjusting

wrenches are removed from tool before turning it on.

5. KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

6. AVOID DANGEROUS ENVIRONMENT. Don’t use

power tools in damp or wet locations, or expose them to

rain. Keep work area well lighted.

7. KEEP CHILDREN AND VISITORS AWAY. All children

and visitors should be kept a safe distance from

work area.

All specication, dimensions and design characteristics shown in this catalogue are subject to change without notice.

Max. depth of cut at 90º:

3/18” (79 mm)

Max. depth of cut at 45º:

2-1/5” (56.25 mm)

Saw blade tilt left: 0º - 45º

Table size: 20-1/8” x 27”

MODEL KN RXW-10M3

8. MAKE WORKSHOP KID PROOF with padlocks, master

switch, or by removing starter keys.

9. DON’T FORCE TOOL. It will do the job better and be

safer at the rate for which it was designed.

10. USE RIGHT TOOL. Don’t force tool or attachment to do

a job for which it was not designed.

11. WEAR PROPER APPAREL. No loose clothing, gloves,

neckties, rings, bracelets, or jewelry to get caught in

moving parts. Non-slip footwear is recommended. Wear

protective hair covering to contain long hair.

12. ALWAYS USE SAFETY GLASSES. Also use face or dust

mask if cutting operation is dusty. Everyday eyeglasses

only have impact resistant lenses, they are NOT safety

glasses.

13. SECURE WORK. Use clamps or a vise to hold work,

when practical. It’s safer than using your hand and frees

both hands to operate tool.

14. DON’T OVERREACH. Keep your proper footing and

balance at all times.

Miter gauge left & right:

30º

Fence size: 36” x 1-3/4” x 2-5/8”

Overal dimensions:

49-3/4” x 41-3/4” x 38-1/8”

Net/gross weight: 103 / 114 Kg.