Switch actuator, 1-gang

■ Load physical address and application program using the ETS.

Safe-state mode

The safe state mode stops the execution of the loaded application program.

Only the system software of the device is still functional. ETS diagnosis functions and pro-

gramming of the device are possible.

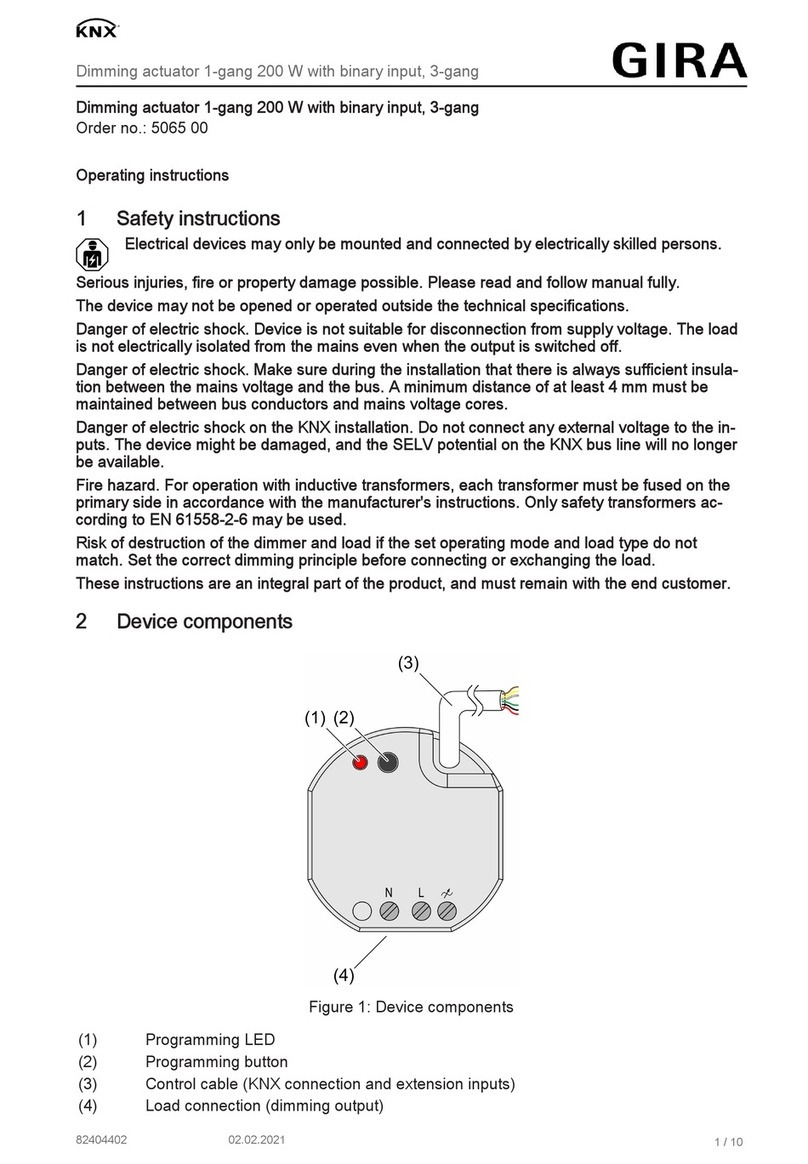

Activating the safe-state mode

■ Switch off the bus voltage or disconnect the device from the KNX.

■ Wait about 10 s.

■ Press and hold down the programming button.

■ Switch on the bus voltage or connect the device to KNX. Release the programming button

only after the programming LED starts flashing slowly.

The safe-state mode is activated.

With a new brief press of the programming button, the programming mode can be

switched on and off as usual also in the safe-state mode. If Programming mode is active,

the programming LED stops flashing.

Deactivating safe-state mode

■ Switch off bus voltage (wait approx. 10 s) or carry out ETS programming.

Master reset

The master reset restores the basic device setting (physical address 15.15.255, firmware re-

mains in place). The device must then be recommissioned with the ETS.

During secure operation: A master reset deactivates device security. The device can then be re-

commissioned with the device certificate.

Performing a master reset

Precondition: The safe-state mode is activated.

■ Press and hold down the programming button for > 5 s.

The programming LED flashes quickly.

The device performs a master reset, restarts and is ready for operation again after ap-

prox. 5 s.

Restoring the device to factory settings

Devices can be reset to factory settings with the Jung ETS Service App. This function uses the

firmware contained in the device that was active at the time of delivery (delivery state). Restor-

ing the factory settings causes the devices to lose their physical address and configuration.

5 Technical data

Ambient conditions

Ambient temperature -5 ... +45 °C

Storage/transport temperature -25 ... +70 °C

Dimensions (W × H × D) 48 x 50 x 28 mm

KNX

KNX medium TP256

Commissioning mode S-mode

Rated voltage KNX DC 21 ... 32 V SELV

Current consumption KNX 5 ... 18 mA

Connection mode KNX Connection terminal on control cable

Outputs

6 / 8

82404313 25.05.2021

J0082404313