DVZ

page 2 DVZ K13/0423

1. Contents

1.Contents ........................................................................................................ 2

2.Note .............................................................................................................. 3

3.Instrument Inspection .................................................................................... 3

4.Regulation Use ............................................................................................. 4

5.Operating Principle ........................................................................................ 4

6.Mechanical Connection ................................................................................. 5

6.1Check operating conditions: ................................................................. 5

6.2Installation ............................................................................................ 5

7.Electrical Connection .................................................................................... 6

7.1General ................................................................................................ 6

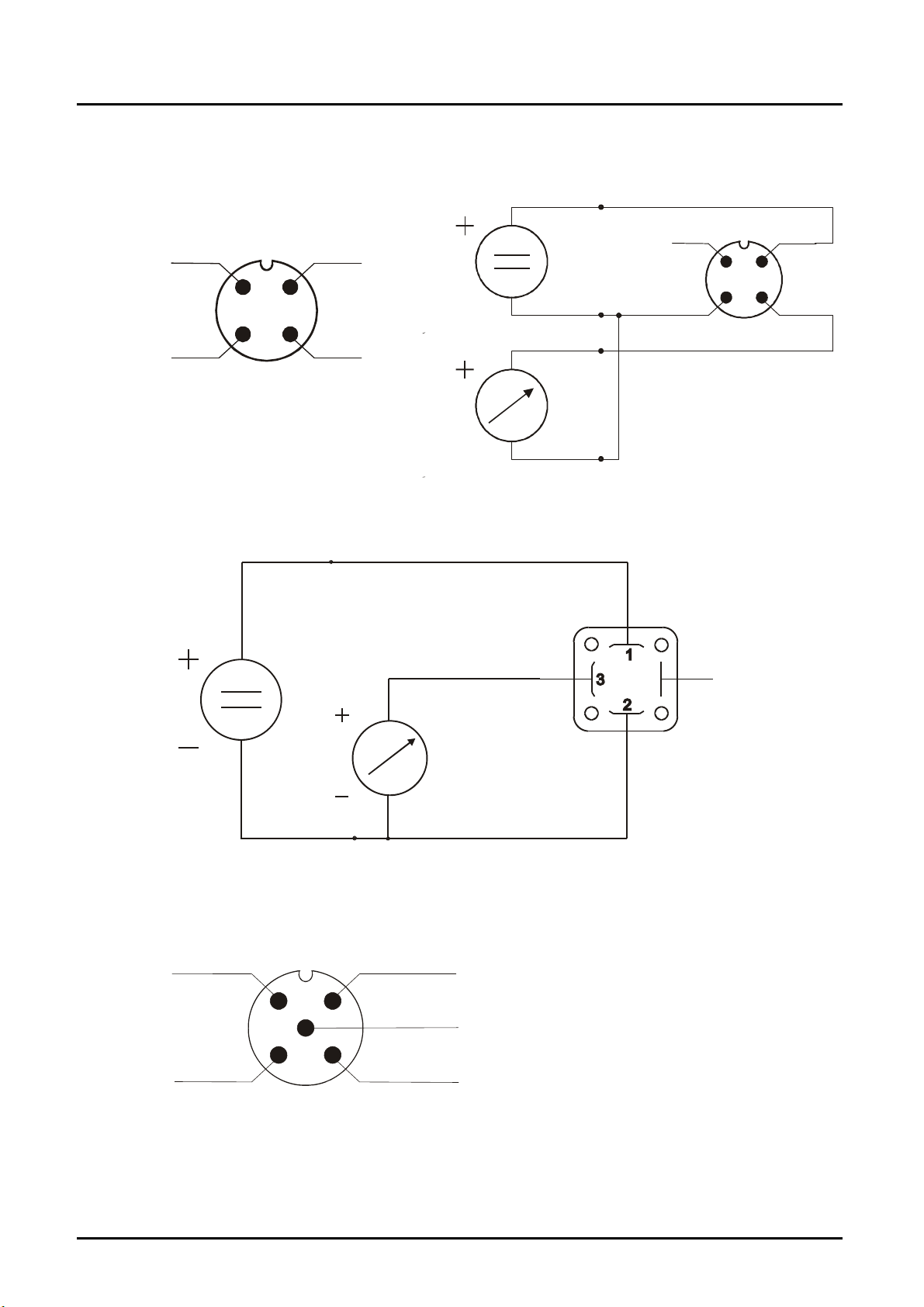

7.2DVZ-...S300 ......................................................................................... 6

7.3DVZ-...S30D ........................................................................................ 6

7.4DVZ-...F300; DVZ-...L3x3 .................................................................... 7

7.5DVZ-...L443 ......................................................................................... 7

7.6DVZ-...C30 ........................................................................................... 7

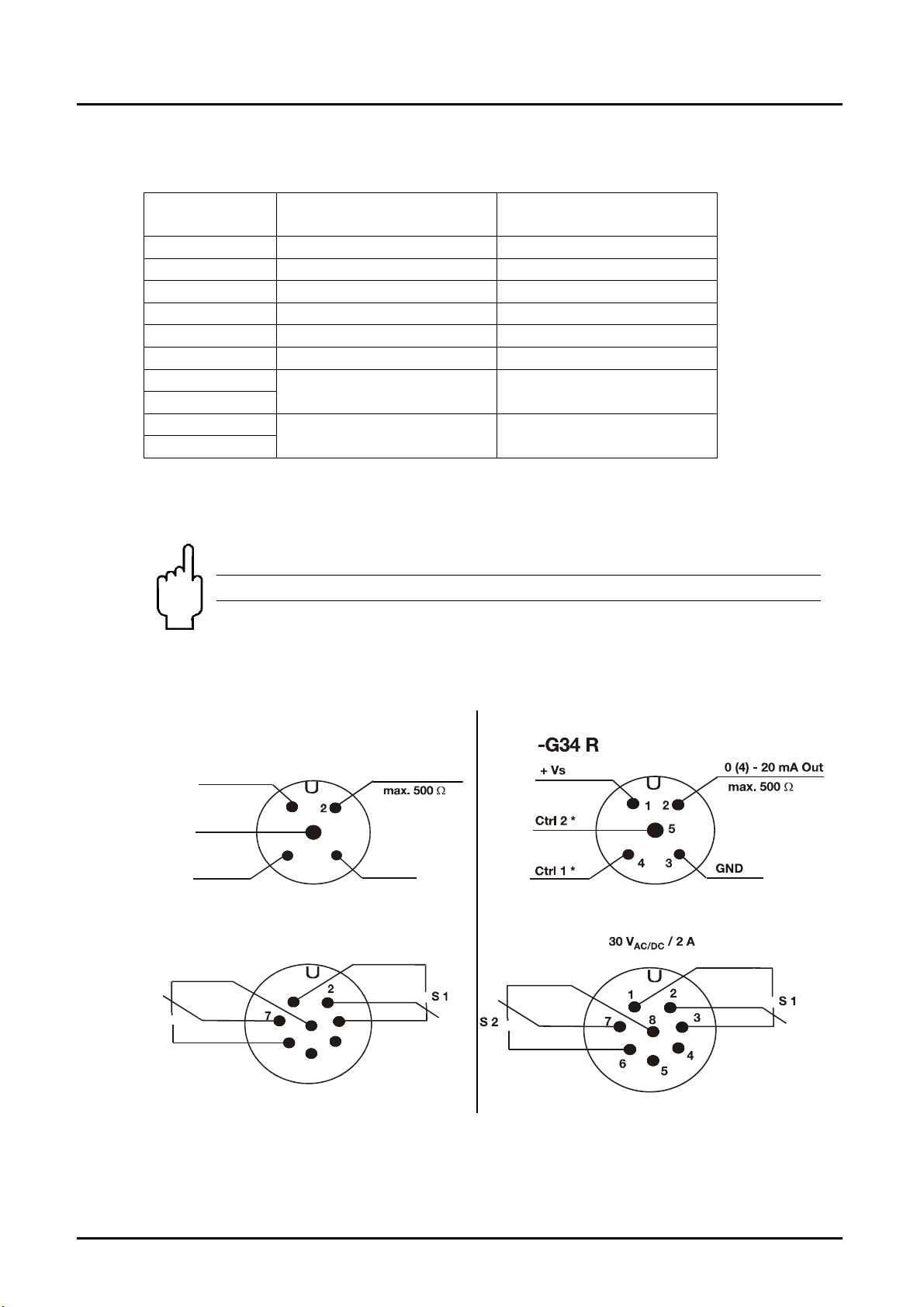

7.7DVZ-...C34 ........................................................................................... 8

7.8DVZ-...Ex4R, DVZ-...Gx4R .................................................................. 9

8.Operation .................................................................................................... 10

8.1Switch point setting DVZ-...S300, DVZ-…S30D ................................ 10

8.2Counter electronics DVZ-…Ex4R ...................................................... 10

8.3Dosing electronics DVZ-…Gx4R ....................................................... 10

9.Adjustments – Compact Electronic DVZ-...C3............................................. 11

9.1Button function ................................................................................... 11

9.2Settings .............................................................................................. 11

9.3Value setting ...................................................................................... 12

9.4Set-up mode ...................................................................................... 13

9.5Main menu items ............................................................................... 15

10.Maintenance ............................................................................................... 18

11.Technical Information .................................................................................. 18

12.Order Codes ............................................................................................... 18

13.Dimensions ................................................................................................. 18

14.Disposal ...................................................................................................... 19

15.EU Declaration of Conformity ...................................................................... 20

16.UK Declaration of Conformity ...................................................................... 21

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

Internet: www.kobold.com