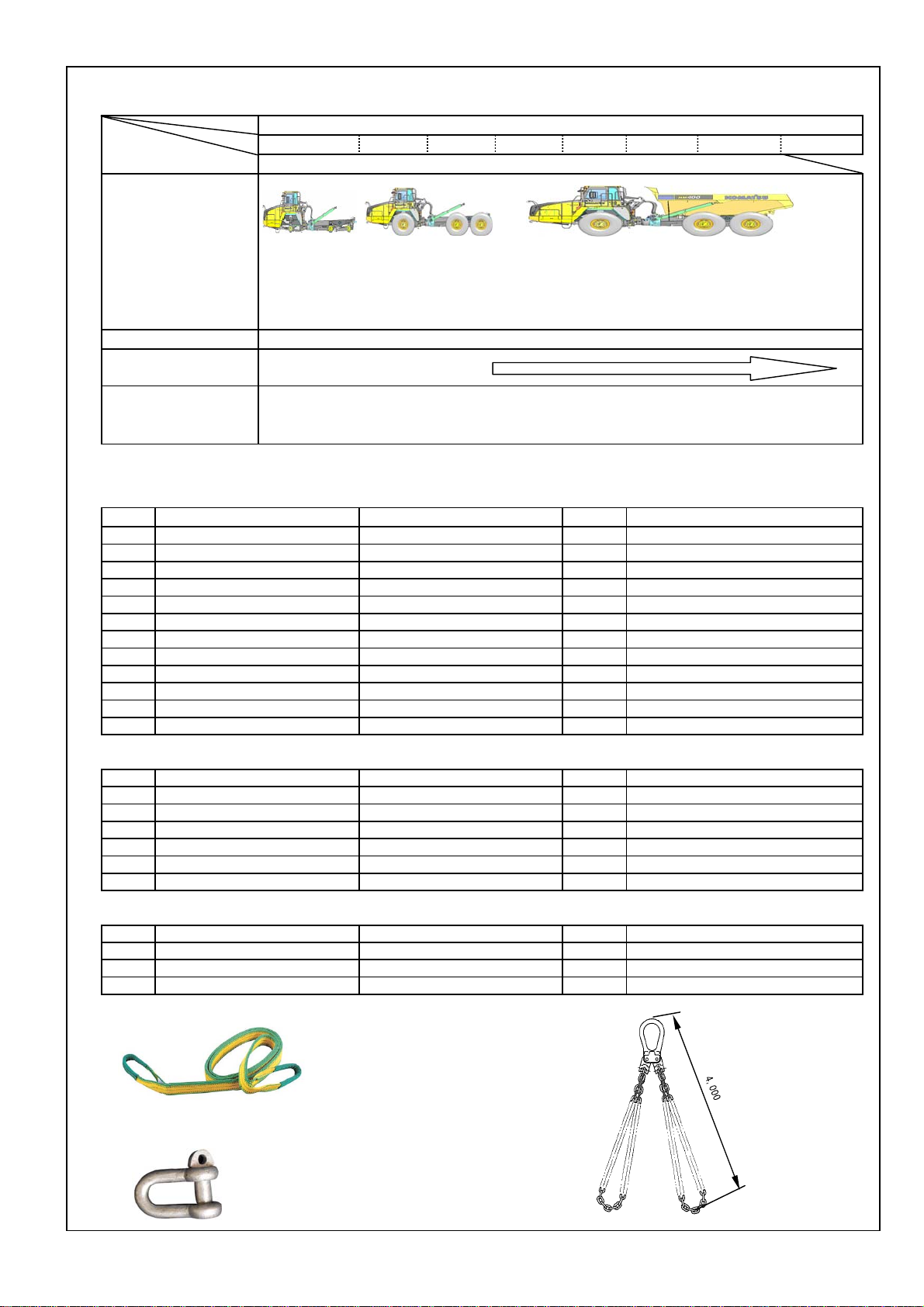

3. Assembly procedure, necessary equipments, and schedule

Day

Hour 1 23456 7 8

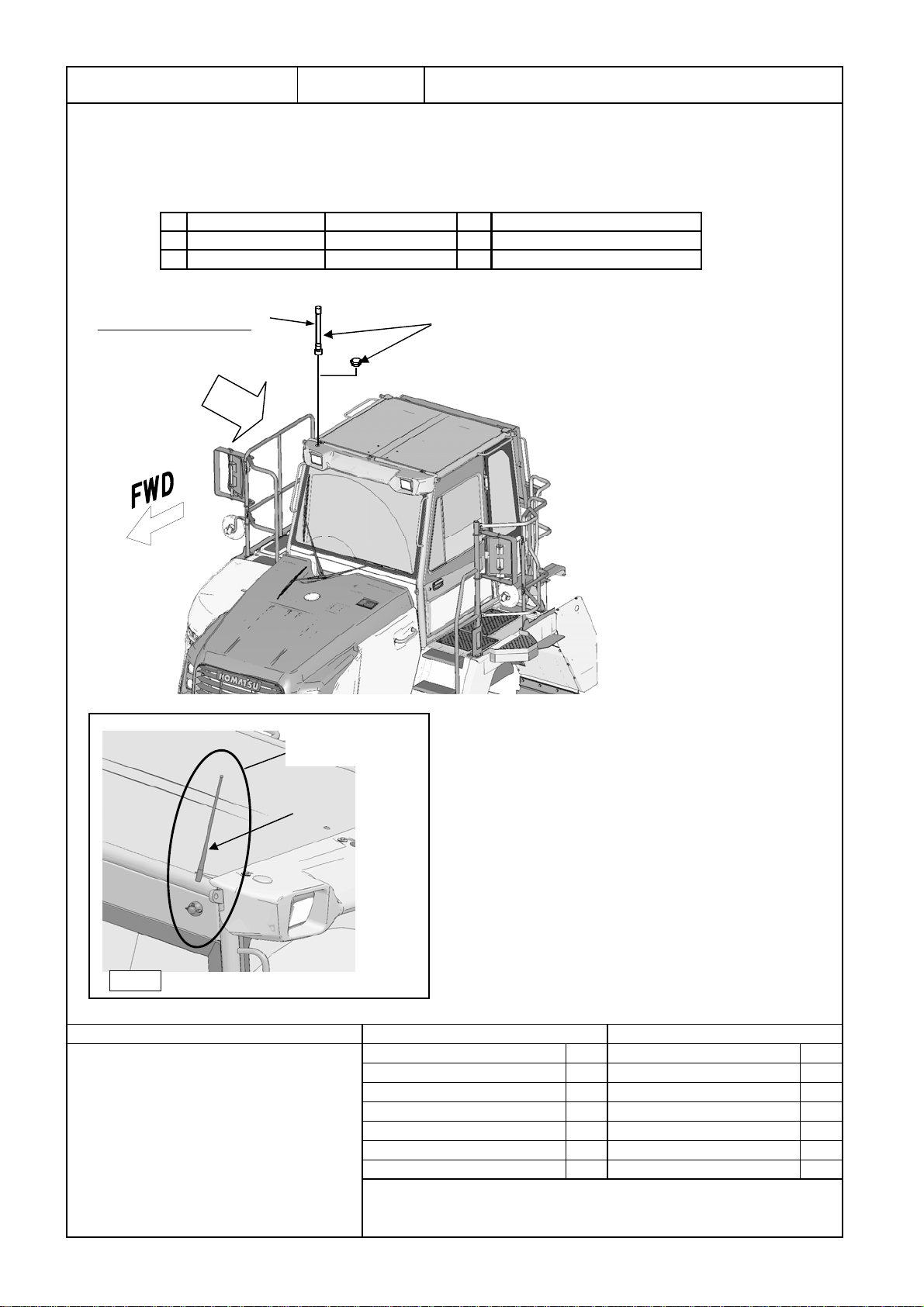

(1) Positioning chassis (3) Mounting body (4) Adjusting each parts

(2) Installing tires Mirror and antenna

(5) Inspection

Meeting before work Completion of assembly

Unloading

Starting assembly

4. Necessary tools and equipments

(1) Necessary tools

No. Q'ty

1 1 set

21

31

4 1 set

51

61

7 1 set

81

91

10 1 set

11 1

12 1

(2) Necessary equipments

No. Q'ty

12

21

31

41

52

612

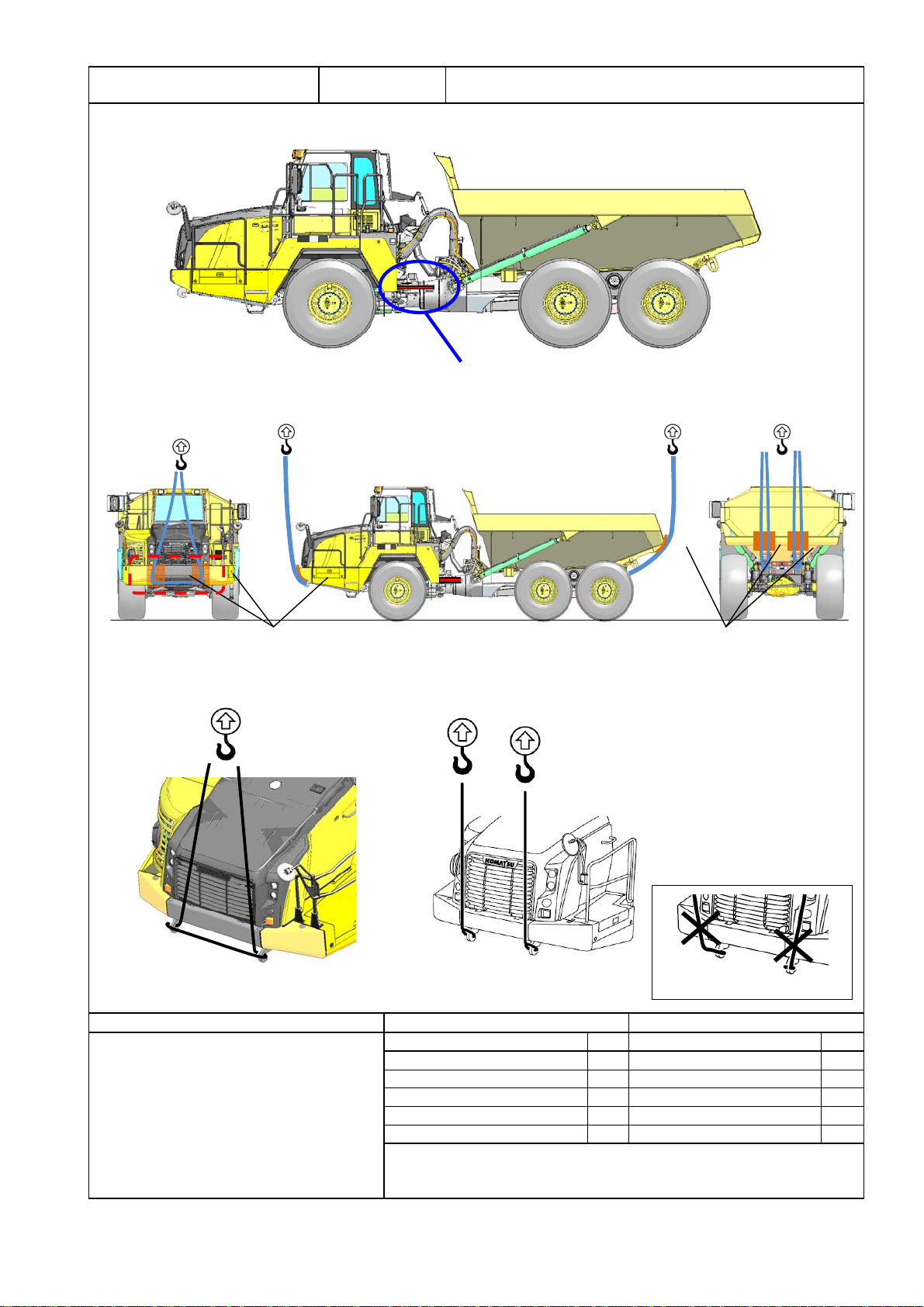

(3) Necessary lifting tools

No. Q'ty

14

21

34

Lifting tire L: 4,000 Chain diamete φ6.3 For tire chassis

Shackle Withstand load :Min. 1 ton For connecting body and sling tools

Equipment name Specifications Remarks

Nylon sling For 15 ton xL: 4,000 For slinging protector

Steel plate t 9 × 1,219 × 2,438 For setting bare machine in place

Wood block 400 × 400 × 900 For setting bare machine in place

Compressor Capacity: Min. 32 ℓFor impact wrench

Stepladder (Work stand) 4 steps (About 1.5m) For work

Crane Min. 25 ton For slinging protector

Forklift Min. 2 ton For mounting tire

Bar For adjustment of holes when mounting tire

Equipment name Specifications Remarks

Suspension gas pouring tool 7926-10-1000 For adjusting suspension pressure

Touch-up paint spray can

Impact wrench GT-S22m or equivalent For mounting tire

Torque wrench Can be measured 927 Nm { 94.5 kgm} For mounting tire

Number of workers

Socket

SpecificationsTool name

Ring wrench

Socket

Remarks

Standard tools (Wrench set)

36 mm (Entry corner 25.4)

2

1st day

Assembly Procedure No.

Assembly unit

No.0010-0900

Remarks

For tightening each place

For mounting tire

For tightening each placeStandard tools ( Socket set )

Paint spray can Clear For touch-up bolt head

Impact wrench For tightening each place

Extension bar Entry corner 25.4 × L:160 For mounting tire

Natural yellow For touch-up body and hoist cylinder

Grease gun For each parts grease-up

Length : 4,000 mm

Specification load : 15 ton

Chain diameter

φ 6.3 mm

Specification load :

3.20 ton

21

3