6

Maintenance

Warning

Always stop the machine prior to

greasing, adjustment or repair.

Greasing

SUC 100E, SUC150E, SUC 200 E,

SUC 300E:

All bearings are lubricated for life

and require no further greasing.

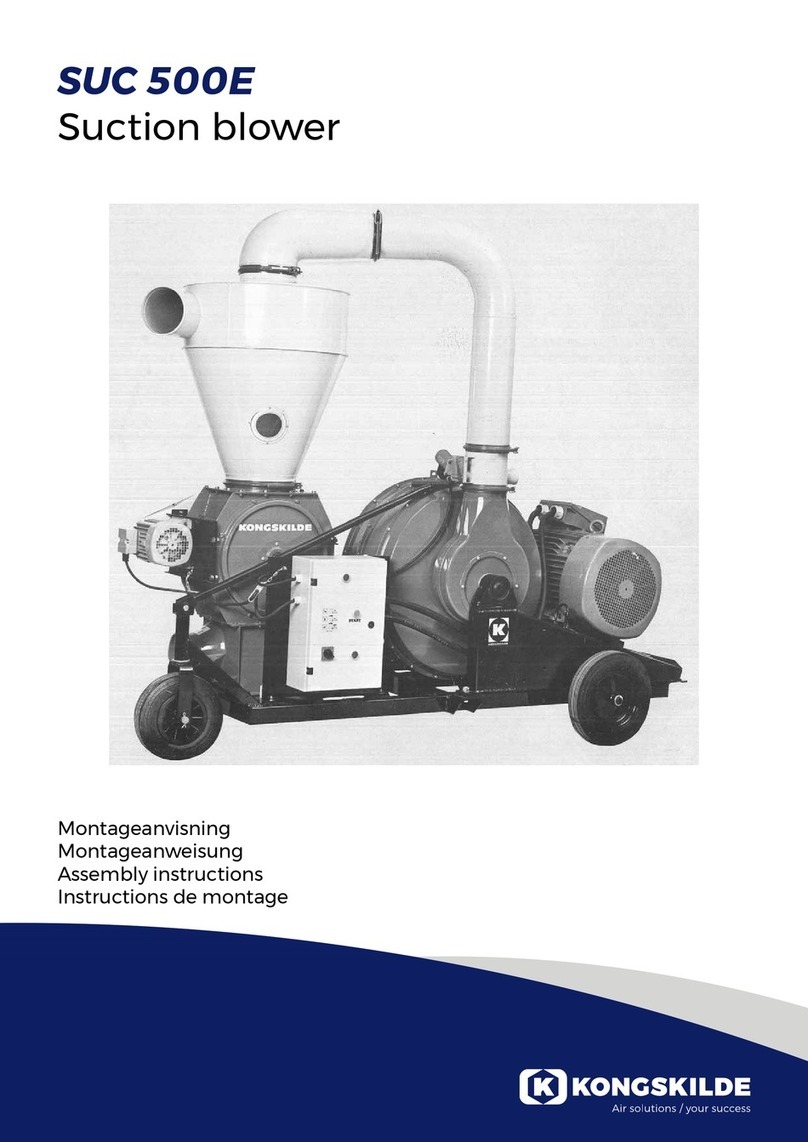

SUC 500E:

Grease the bearings on the blower

belt side every 200 working hours.

Use a lithium base grease of mini-

mum quality as Mobil Mobilux EP2

Belt Adjustment

Check V-belt tension regularly, espe-

cially when they are new. New V-belts

normally require adjustment after 15

minutes and again after 2- 3 hours

work.

Belt tension check

To inspect the V-belts remove the belt

guard. Use, for instance, a tension

tester to check the belts.

Order No.: 121 130 071.

Check the tension of all the belts. If it is

not possible to adjust one set of belts

so that all the belts have the proper

tension the whole set must be replaced.

SUC 100E,

Blower:

Depressoneofthebelts.Atadeec-

tion of 9.5 mm the force should be

between 1.5 and 2 kg.

Rotary valve:

Depress one of the belts. At a de-

ectionof4mmtheforceshouldbe

between 0.5 and 1 kg.

or Esso Beacon EP2. Regrease

with approx. 20 cm3= 20 g each

time. Never overgrease the bea-

rings.Ifthecasingislledwithtoo

much grease, the bearing will get

hot.

Cleaning

The screen inside the top of the

cyclone should be cleaned regu-

larly.

The material conveyed will determi-

ne how often cleaning is required.

If the screen is blocked the capacity

of the blower will be reduced.

Motors

Do not cover up the motors. Keep

them free of dirt reducing the coo-

ling.

Retightening

On a new blower all bolts and

screws are to be retightened after

therstworkingday.Apartfrom

that make sure that they are tight at

all times.

Storage

Clean and grease the suction

blower before storage.

To prevent rust, store the machine

in a dry place protected against

wind and moisture.

SUC 150E,

Blower:

Depress one of the belts. At a de-

ectionof9mmtheforceshouldbe

between 1.5 and 2.5 kg.

Rotary valve:

Depress one of the belts. At a de-

ectionof4mmtheforceshouldbe

between 0.5 and 1 kg.

SUC 200E,

Blower:

Depress one of the belts. At a de-

ectionof9mmtheforceshouldbe

between 1.9 and 2.8 kg.

Rotary valve:

Depress one of the belts. At a de-

ectionof4mmtheforceshouldbe

between 0.5 and 1 kg.

SUC 300E,

Blower:

Depress one of the belts. At a de-

ectionof9mmtheforceshouldbe

between 2 and 2.5 kg.

Rotary valve:

Depressoneofthebelts.Atadeec-

tion of 3.5 mm the force should be

between 1 and 1.5 kg.

SUC 500E,

Blower:

Depressoneofthebelts.Atadeec-

tion of 9.5 mm the force should be

between 3 and 5 kg.

Rotary valve:

Depressoneofthebelts.Atadeec-

tion of 3.5 mm the force should be

between 1.5 and 2 kg.

If the belts are too tight both the bearin-

gs and the belts will be overloaded and

their life considerably reduced.

If the belts are too slack they will slide

on the belt pulleys and wear quickly. At

the same time the blower will run too

slowly reducing conveying capacity.

How to use the tension meter

1. Position the lower rubber ring at

thedeectiondistanceonthelower

scale. Leave the upper rubber ring

against the the edge of the sleeve.

2. At center of span length apply force,

with tension tester perpendicular

to the span, large enough to make

thedeectiondistancecorrespond

to the edge of the adjacent belt. A

straight edge across the belts will

insure accuracy of reading.

3. Remove the tension tester and

readthedeectionforceon

upper scale, at the top edge of

the rubber ring.

4. If the force is too high, belts should

be slackened, and if the force is too

low, belts should be tightened.

Tightening of belts

Make sure that the belt pulleys remain

aligned during tightening. Check by

putting a straight board against the pul-

leys to see whether both pulleys bear

against the board.

The rotary valva will remain aligned

during belt tightening.