Kongskilde KPC 80 User manual

KPC 80 - 200

Dual strip cutters

Manual

Betriebsanleitung

Manuel de service

Instrucciones de funcionamiento

Podręcznik użytkownika

Brugsanvisning

2

GB

This user manual applies to the Kongskilde guillotine

cutter model KPC 80-200.

Description:

The KPC cutter is designed for cutting down trims of

plastic foils, paper and cardboard.

The maximum thickness of plastic foils is 300 µm, while

the maximum thickness of paper and cardboard is 800

g/m2.

The cutter is designed for mounting in an enclosed pipe

system, that is, with a pipeline mounted both at the inlet

and outlet.

The cutter is designed to work with continuous vacuum

and has no pressure loss on the suction side when it is

cutting. The cutter is built to be an alternative to rotating

cutters that cuts the material into small pieces, gener-

ates a lot of dust and has a high noise level. With the

KPC cutter, the waste can be cut into longer strips, so

it is possible to bale. Furthermore, the reduced number

of cuts makes the dust created by the cutter extremely

low.

Only use the KPC cutter for cutting the materials it is

designed for, due to risk of knife destruction or damage.

Warning notes:

Avoid accidents by always following the safety instruc-

tions given in the user manual and on the safety signs

located on the cutter.

The cutter must be installed in a closed duct system,

without access to moving parts..

Any foreign objects allowed into the system, intentional-

ly or unintentionally, may eventually damage the cutter.

Lack of supervision of the cutter can result in wear

and/or damage to vital parts, see section "Service and

maintenance".

Ensure that both inlet/outlet pipes are intact and prop-

erly secured during operation.

Always disconnect electricity and compressed air to the

cutter prior to repair and maintenance.

Never do any dismounting or service to the cutting

device before disconnecting the power plug and com-

pressed air.

Never put your hand into the cutter inlet or outlet during

operation.

The cutter should be mounted in an accessible location

for maintenance. The working area around the cutter

should be clear and trip free when carrying out main-

tenance. Use gloves when working with the knifes, the

edges are sharp.

Make sure that there is adequate lighting when working

on the cutter.

In cases where is it necessary to remove material

blocking the moveable knife, compressed air and elec-

tricity must always be switched off to prevent start up

of the cutter. If removal of material in the cutter is done

while the power / air is switched on, the cutter will start

as soon as the blocking material is removed. This in-

volves great risk of personal injuries!

In case of abnormal vibrations or noise, stop the cutter

immediately and examine the cause. In case of doubt,

skilled assistance must be called in for repair and main-

tenance.

Take care that the cutter is securely installed, onto a

stable surface, a to avoid unintensional movement of

the cutter.

To avoid any unintentional contact with the moving

knife, pipes of minimum 850 mm length, with a diam-

eter of maximum Ø 200 mm must be installed onto the

inlet and outlet connections.

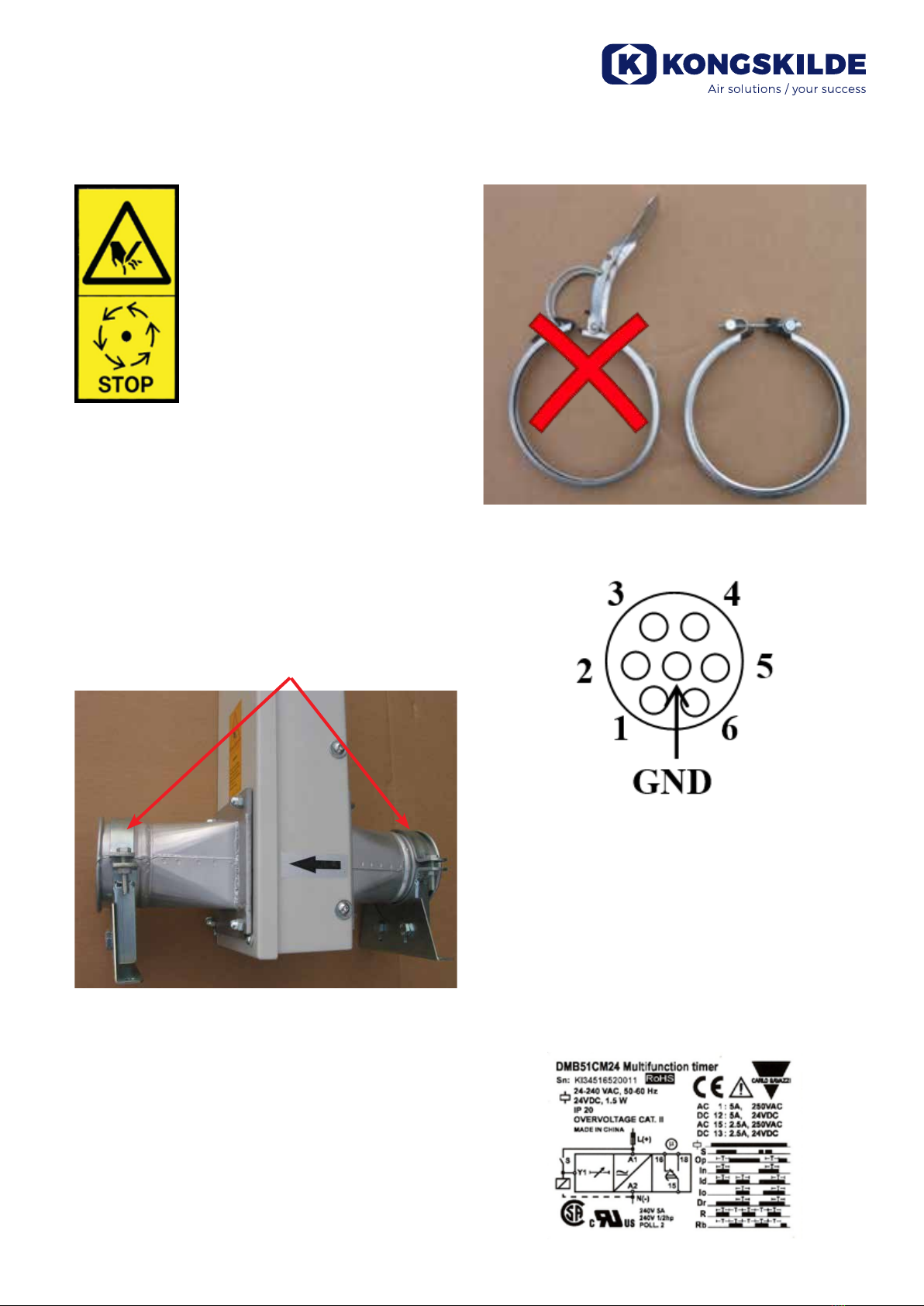

These pipes must be installed with bolt clamps, where

tools are necessary for dismantling.

In case it is not possible to use minimum 850 mm

tubes, it must be insured that there within minimum

850 mm from the separator are used bolt clamps,

where tools are necessary for dismantling.

The reason for this is, that according to EU-directive

2006/42/EC (Machinery Directive), it is not allowed for

any unauthorized personnel to gain access to rotating

parts. In case quick couplings are used, unautorized

personnel could dismantle the tubing, and have access

to the cutting knife.

Warning signs:

Warning signs with symbols without text are found on

the cutter. The symbols are explained below.

Read the user manual carefully and

observe the warning texts in the user

manual and on the cutter.

3

Inlet, outlet or other guards must not

be opened or removed while the cutter

is in operation.

Mounting:

The cutter must always be installed with minimum 850

mm straight pipe on each side of the cutter, so nobody

can reach the cutting device with a hand. Use the en-

closed clear acrylic 1 meter pipe on the exit side. The

operator can then physically se that the cutter is work-

ing correctly.

When placing the cutting device, make sure that the air

ow direction is correct. See the arrow on the cutter´s

enclosure.

The cutter can be xed by using 2 pcs. pipe support,

one on each side of the cutter.

The cutting device can be xed to any stabile layer,

hanging or standing, in any angle, from horizontal to

vertical.

Always use bolt clamps and not quick release clamps

for connecting the cutter with the pipe system.

Electrical installation:

Pin 1 - Solenoid signal

Pin 2 - 24VDC solenoid

GND - Timer box green-yellow connector

Connection:

The power can be taken from the machine, so the cut-

ter is in operation only when the machine is running.

Con A1 24VDC+ (machine run signal)

Con A2 24VDC-

Con 15 24VDC+

Con 18 PIN 1 in connector plug for cutter

4

Timer settings:

Function mode is set on Rb

Examples:

8 sec cut 15 sec cut

Time setting 8 2,5

Time range 1 sec 6 sec

Electrical diagram:

Service and maintenance:

For your safety, read the safety instructions before

you work on the device.

Maintenance

In general there is no frequently maintenance, such as

greasing and oiling.

Cleaning

Cleaning of the cutting devices is needed from time to

time, depending of the type of material that is running.

Exchanging or turning knifes

1. Release air pressure (A)

Disconnect air pipe (B)

Disconnect power plug (C)

A

B

C

5

2. Remove the 4 screws on the lower knife.

Turn it 180º or replace it.

Before the knife is tted, both the knife and the

base must be 100% clean. Use cleaning liquid

like petroleum or similar.

Then attach the knife.

3. Use the same procedure for the upper knife.

4. Turn the cutting device. Use the same proce

dure for the center knife.

This can’t be rotated as its using both sides.

5. Test the cutting device before placing it back in

the box on the pipe system.

Free play on knifes

There can be two reasons for adjusting the distance on

the strip cutter:

1. Material is not cut correctly and material is forced

in between the blades and the middle knife is not

moving up and down. Before making any adjust-

ments, please make sure that the knifes are still

sharp and don’t have any marks on the knife edge.

In this case we will have to make less distance be-

tween the body and the guide rail holders. Typically

0,02mm.

2. Dust can build up in the bushings, so there is no

tolerance in between the bushing and the rail. The

knifes will then go to hard against each other and it

can’t be moved back by the force of the air cylinder.

In this case we will have to make more distance be-

tween the body and the guide rail holders. Typically

0,03mm.

When adjusting the distance you must always start in

the side where the knife touches rst (pos. 1 or 3).

Then test the cutter and see if this is enough or modi-

cation in the other side is necessary (pos. 2 or 4).

12

34

6

Insert or remove precision steel

Loosen the screw in the corner where you want to

modify.

All cutters has precision steel in all 4 points, so when

you add, make sure that the inserted piece is on top of

what’s already inserted (not always one piece).

!! Before testing make sure that all bolts and screws are

tightened.

For distance adjustment use precision steel band:

The steel precision steel band can be purchased in

most professional tool shops.

7

EC Declaration of Conformity

Kongskilde Industries A/S, DK-4180 Sorø - Denmark, hereby declares that:

Kongskilde cutters type KPC 80 - 200

Are produced in conformity with the following EC-directives:

• Machinery Directive 2006/42/EC

• Electro Magnetic Compatibility Directive 2014/30/EC

• Low Voltage Directive 2014/35/EC

Furthermore, all electric components used are UL listed to comply with US standards.

Kongskilde Industries A/S

Sorø 01.07.2016

Mogens Rüdiger

CEO

Kongskilde Industries A/S

Skælskørvej 64

DK - 4180 Sorø

Tel. +45 72 17 60 00

www.kongskilde-industries.com

121 116 344 You can always nd the latest version of the manuals at 20.01.2020

www.kongskilde-industries.com

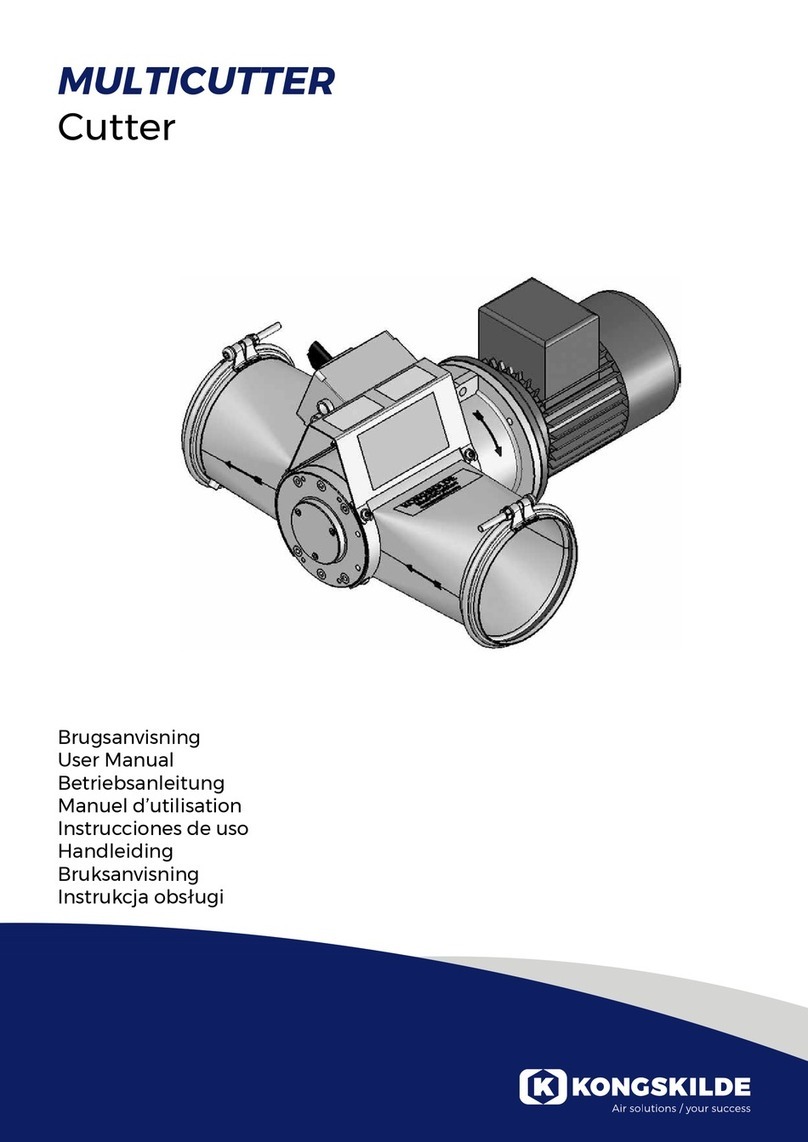

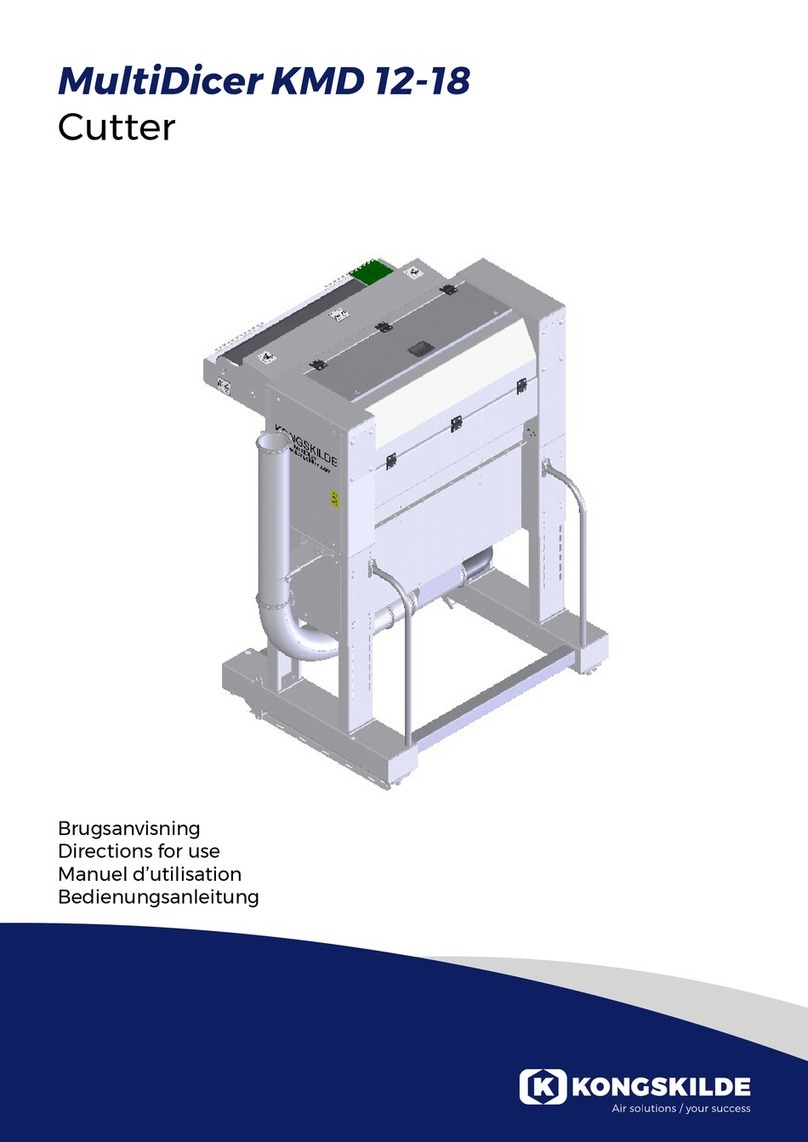

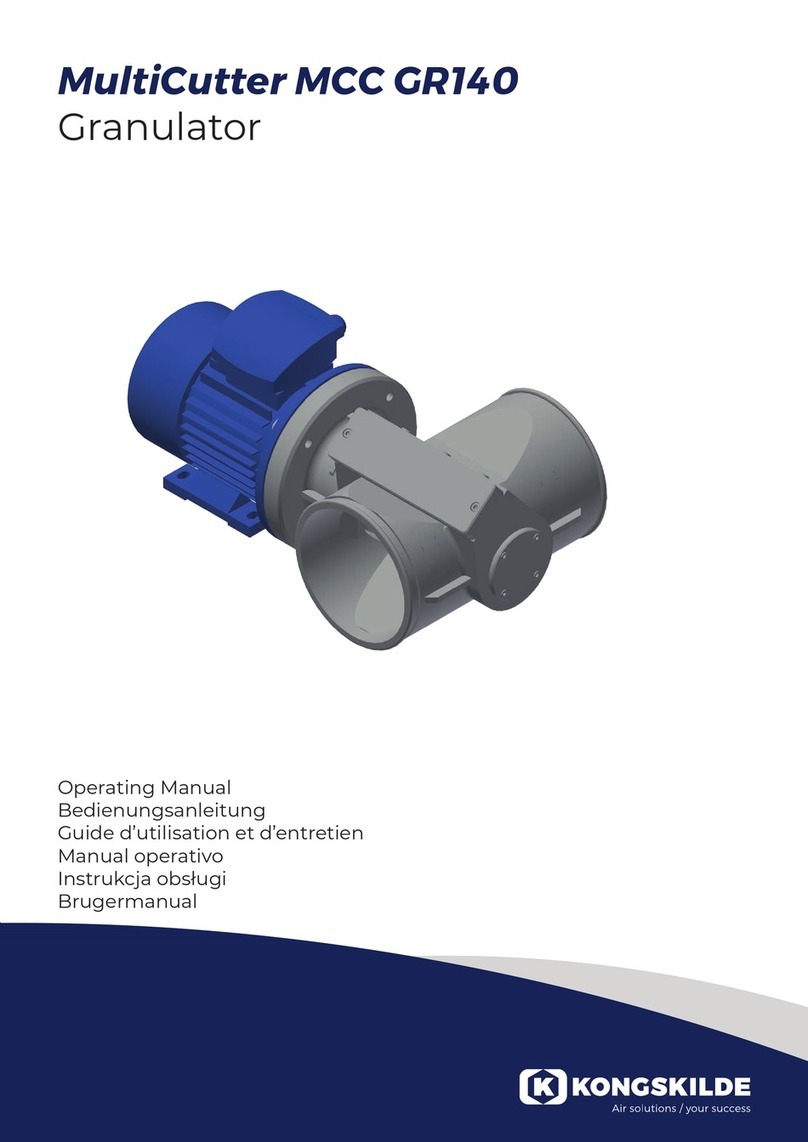

This manual suits for next models

1

Table of contents

Other Kongskilde Cutter manuals

Popular Cutter manuals by other brands

Milwaukee

Milwaukee HEAVY DUTY M12 FCOT Original instructions

SignWarehouse.com

SignWarehouse.com Bobcat BA-60 user manual

Makita

Makita 4112HS instruction manual

GEISMAR STUMEC

GEISMAR STUMEC MTZ 350S manual

Hitachi

Hitachi CM 4SB2 Safety instructions and instruction manual

Dexter Laundry

Dexter Laundry 800ETC1-20030.1 instruction manual