Direct link to operating manual

KOSTAL Industrie Elektrik GmbH

Fax + 49 (0)2351 16-2400

All names, trademarks, product names or other designations given in this manual may

be legally protected even if this is not labelled as such (e.g. as a trademark). KOSTAL

Industrie Elektrik GmbH accepts no liability and gives no assurance that they can be

freely used. The illustrations and texts have been compiled with great care. However,

the possibility of errors cannot be ruled out. The compilation is made without any

guarantee.

General note on gender equality

KOSTAL Industrie Elektrik GmbH is aware of the importance of language with regard to

the equality of women and men and always makes an effort to reflect this in the

documentation. Nevertheless, for the sake of readability we are unable to use non-

gender-specific terms throughout and use the masculine form instead.

© 2019 KOSTAL Industrie Elektrik GmbH

All rights reserved by KOSTAL Industrie Elektrik GmbH, including those of reproduction

by photocopy and storage in electronic media. Commercial use or distribution of the

texts, displayed models, diagrams and photographs appearing in this product is not

permitted.

This manual may not be reproduced, stored, transmitted or translated in any form or by

means of any medium - in whole or in part - without prior written permission.

The chapters marked with this symbol form part of the

complete operating manual.

Please read and note the information provided there.

Complete operating manual

You will find a detailed operating manual on “Functional safety”, including

application examples, online at

http://www.kostal-industrie-elektrik.com/INVEOR_M_Functional_Safety

Proper use

IMPORTANT INFORMATION

Using drive controllers in equipment that is not fixed is considered as an

exceptional environmental condition and is only permitted if allowed by the

standards and guidelines applicable on site.

Only allow appropriately qualified staff to undertake assembly and disassembly.

Only use staff who are trained in mounting, installation, commissioning and

handling.

Do not modify the drive controller.

Observe general and national safety and accident prevention regulations

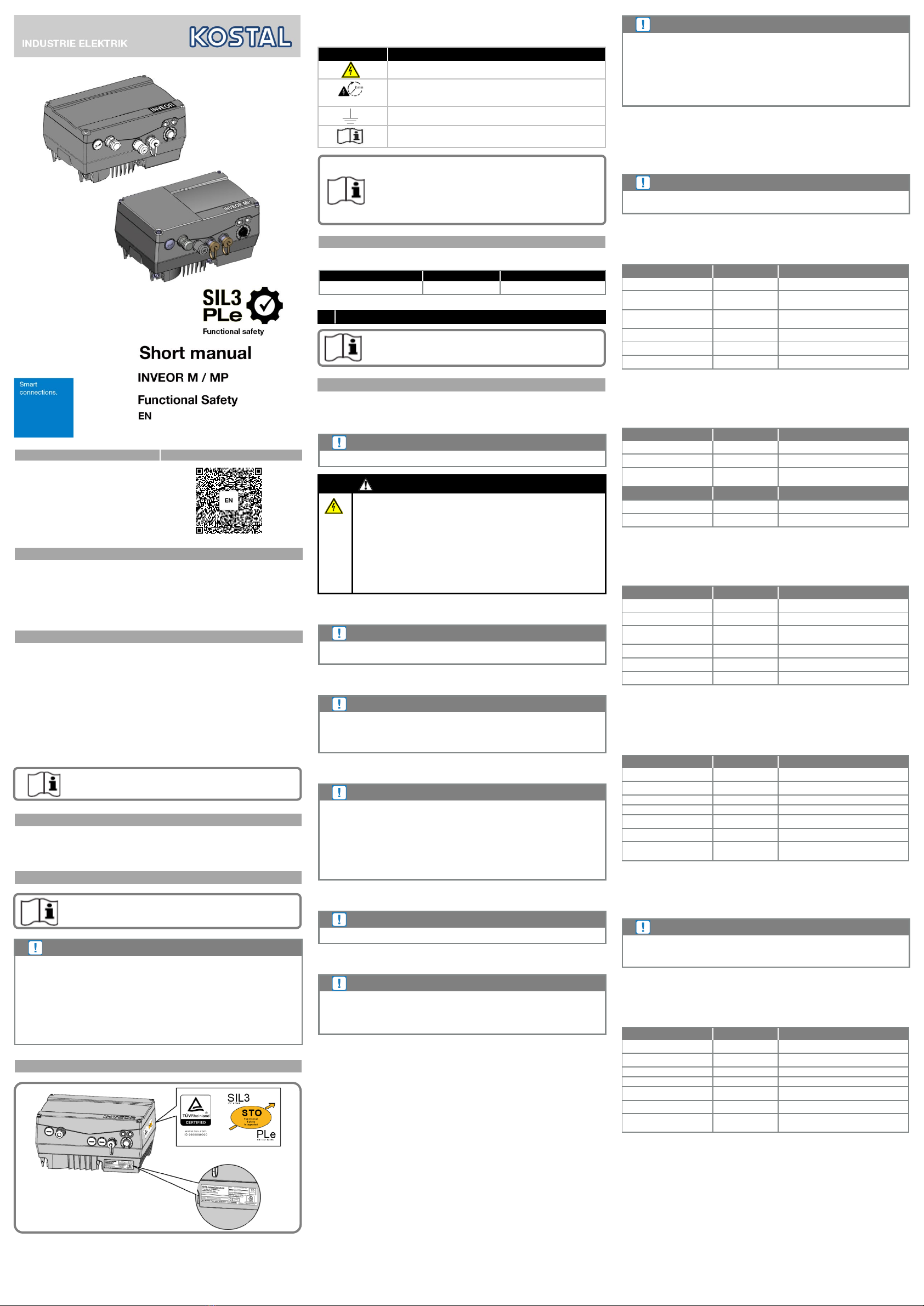

Labels on the drive controller

Signs and labels are applied to the housing of the drive controller.

These signs and labels may not be altered or removed.

Danger due to electrical shock and discharge

Danger due to electrical shock and discharge.

Wait two minutes (discharge time of the capacitors) after shut-

down

Additional earth connection

Observe and read operating manual

Qualified staff

Proper use

Responsibility

CE marking

Abbreviations used

Certificate

Contact details and service

If you have any technical questions, please contact our service hotline.

1 SAFETY INSTRUCTIONS

General safety instructions

STO safety instructions

The safety instructions listed in the following are to be observed and obeyed strictly.

Protection from electric shock

IMPORTANT INFORMATION

No protection from electric shock is ensured by the STO status.

DANGER!

Risk of death due to electrical shock!

Death or serious injury!

De-energise drive controller and secure it against being restarted.

The following terminals may lead to dangerous currents even when the

motor is not running:

Supply terminals X1: L1, L2, L3

Motor connection terminals X2: U, V, W

Connecting terminals X6, X7: Relay contacts for relays 1 and 2

PTC terminals T1/T2

Protection from contamination

IMPORTANT INFORMATION

With open housing, contamination degree 2 must be observed in order to ensure

the safety function.

Elimination of errors

IMPORTANT INFORMATION

The STO connection line must be shielded in order to allow the elimination of

errors with regard to external voltage coupling to be applied. The EMC screw

connection provided must be used for

the cable inlet into the INVEOR housing.

Elimination of errors with regard to short circuit

IMPORTANT INFORMATION

With reference to the STO connection line, the “elimination of errors with regard to

short circuit“ is achieved in accordance with DIN EN 13849-2 in that a separate,

shielded cable is used for each channel. Shielding is to be applied at both ends.

The EMC screw connections provided must be used

for this purpose.

If only one shielded cable is used for both STO channels, a safety switch must be

used to detect possible crossovers between the channels to qualify for observation

of the “elimination of errors short circuit“ in accordance with DIN EN 13849-2.

Loss of the safety functions

IMPORTANT INFORMATION

Permanent 24 V voltage to the STO inputs results in the loss of the safety function.

Classification IEC 60204-1

IMPORTANT INFORMATION

The process for the shut-down of the machine drive elements described under

“Stop category-1“ (SS1) can only be realised in connection with an additional

external safety module!

“Stop category-2“ (SS2) is not supported by the drive controller.

Classification IEC 61800-5-2

The following definitions describe the three types of safe stop function.

STO (Safe Torque Off)

No power is supplied to the motor that could cause rotation (or movement in the case

of a linear motor). The drive controller supplies no power to the motor that could

generate torque (or force in the case of a linear motor). This safety function

corresponds to an uncontrolled shut-down according to IEC 60204-1, stop category 0.

IMPORTANT INFORMATION

This safety function can be used when it is necessary to shut off power in order

to prevent an unexpected start.

Where there are external influences (e.g. falling of suspended loads), additional

measures (e.g. mechanical braking), which must be designed to fail safe, may be

necessary to prevent hazards.

In the STO status, the drive is not separated from the energy supply, as only the

activation of the IGBTs is securely switched off.

Safe Stop 1 SS1

The SS1 safety function corresponds to an uncontrolled shut-down according to

IEC 602,04-1, stop category 1. In this case the drive controller does not securely

monitor the motor delay or the motor speed.

IMPORTANT INFORMATION

Secure monitoring of the motor delay is only possible with the use of an external

safety module.

Classification of two-channel EN 62061 without external diagnosis

The classification of the two-channel STO function without external diagnosis meets

the following requirements:

Designation Value Explanation

Safety measure Pulse block ---

Probability of hazardous failures

per hour

DC 60 [%] Diagnosis coverage

SFF 99.24 % Proportion of safe failures

T 20 years Duration of usage

Table: Classification two-channel EN 62061, without external testing

Classification of two-channel EN 62061 with external diagnosis

The classification of the two-channel STO function with external diagnosis meets the

following requirements:

Designation Value Explanation

Safety measure Pulse block ---

SIL 3 Safety integrity level

Probability of hazardous failures

per hour

DC 90 [%] Diagnosis coverage

SFF 99.92 % Proportion of safe failures

T 20 years Duration of usage

Table: Classification of two-channel EN 62061 with external testing

Classification of two-channel EN 62061 with dynamic testing

The classification of the two-channel STO function with dynamic testing meets the

following requirements:

Designation Value Explanation

Safety measure Pulse block ---

SIL 3 Safety integrity level

Probability of hazardous failures

per hour

DC 99 [%] Diagnosis coverage

SFF 99.99 % Proportion of safe failures

T 20 years Duration of usage

Table: Classification of two-channel EN 62061, with enhanced external testing

Classification of two-channel EN ISO 13849-1 without external

diagnosis

The classification of the two-channel STO function without external diagnosis meets

the following requirements:

Designation Value Explanation

Safety measure Pulse block ---

PL e Performance level

Mean time to failure (dangerous)

DC 60 [%] Diagnosis coverage

T 20 years Duration of usage

Max. diagnosis test

interval

Table: Classification of two-channel EN 13849-1, without external testing

The precise way in which a diagnosis test interval works is described in chapter 7 and

in the “Functional safety” operating instructions.

In accordance with ISO 13489-1, the category 3 MTTFd is restricted to 100 years.

IMPORTANT INFORMATION

Cat.3 with DC = 60% actually limits the performance level to d. However, the

increased failure-safety present in this case and documented in the context of the

FMEA is of equal value, and PL e is thus achieved.

Classification of two-channel EN ISO 13849-1 with external

diagnosis

The classification of the two-channel STO function with external diagnosis meets the

following requirements:

Designation Value Explanation

Safety measure Pulse block ---

PL e Performance level

Mean time to failure (dangerous)

DC 90 [%] Diagnosis coverage

T 20 years Duration of usage

Max. diagnosis test

interval

Table: Classification two-channel EN ISO 13849-1 with external diagnosis

The precise way in which a diagnosis test interval works is described in chapter 7 and

in the “Functional safety” operating instructions.

In accordance with ISO 13489-1, the category 3 MTTFd is restricted to 100 years.