6

Keep this manual easily accessible for all users.

IMPORTANT SAFETY INSTRUCTIONS:

»Only use for dry and clean gases. For use with aggres-

sive gases please contact Dresser Actaris Gas for special

versions.

For applications with Hydrogen, after maintenance,

purge the device with inert gas like nitrogen.

Never use with oxygen: Danger of explosion!

• Please respect all national standards and codes of

practices for installation, operation, testing and ser-

vice of gas regulators and of gas pressure regulating

stations.

• Before mounting please check the regulator for pos-

sible damage due to transport.The sealing surfaces

must be clean.

• Arrange enough room for the serving of the regulator.

• To protect the regulator from dirt a sieve or a lter is

recommended.

• The regulator must be installed tension free in the

piping.

• After installation please check the tightness of the

thread connection.

• The technical data given on the name plate must

be respected. If necessary safety devices must be

installed.

• Repairs and maintenance must be done by trained or

qualied personal. Only use original spare parts from

Dresser Actaris Gas. Afterwards a tightness test with

1.1 x PS must be performed. When changing pressure

containing parts their compliance with the PED must

be assured.

• If used with wet gas, internal and external effect of

corrosion has to be checked regularly and in case of

severe corrosion, the regulator has to be replaced.

• The device must be cleaned with a wet cloth only.

Please don’t use solvent or alcohol containing prod-

ucts to clean the regulator.

• Before removing the regulator please depressurise

completely. Some gas may still be inside the regula-

tor and the pipe, therefore sufcient ventilation is

required.

REMARKS FOR USE IN POTENTIALLY

EXPLOSIVEATMOSPHERES (ATEX):

• If lm of rust is possible (ying rust in the immediate

regulator surroundings), all outer aluminium parts have

to be protected accordingly (e.g. by varnish).

• The product must be electrically connected to ad-

equately earthed installation.

• For installation, removing or repair of the regulator on

site, only tools allowed for the corresponding explosion

area can be used.

• The regulator shall not be exposed to: ames, ionised

radiation and ultrasound.

• Ambient temp. conditions must be considered, includ-

ing possible additional heating eects due to other

devices in immediate vicinity.

• Gas pressure regulator according to DIN EN 334 - if not

equipped, with any electronic device - do not have a

potential ignition source and therefore are not in the

scope of European directive 2014/34/EU.

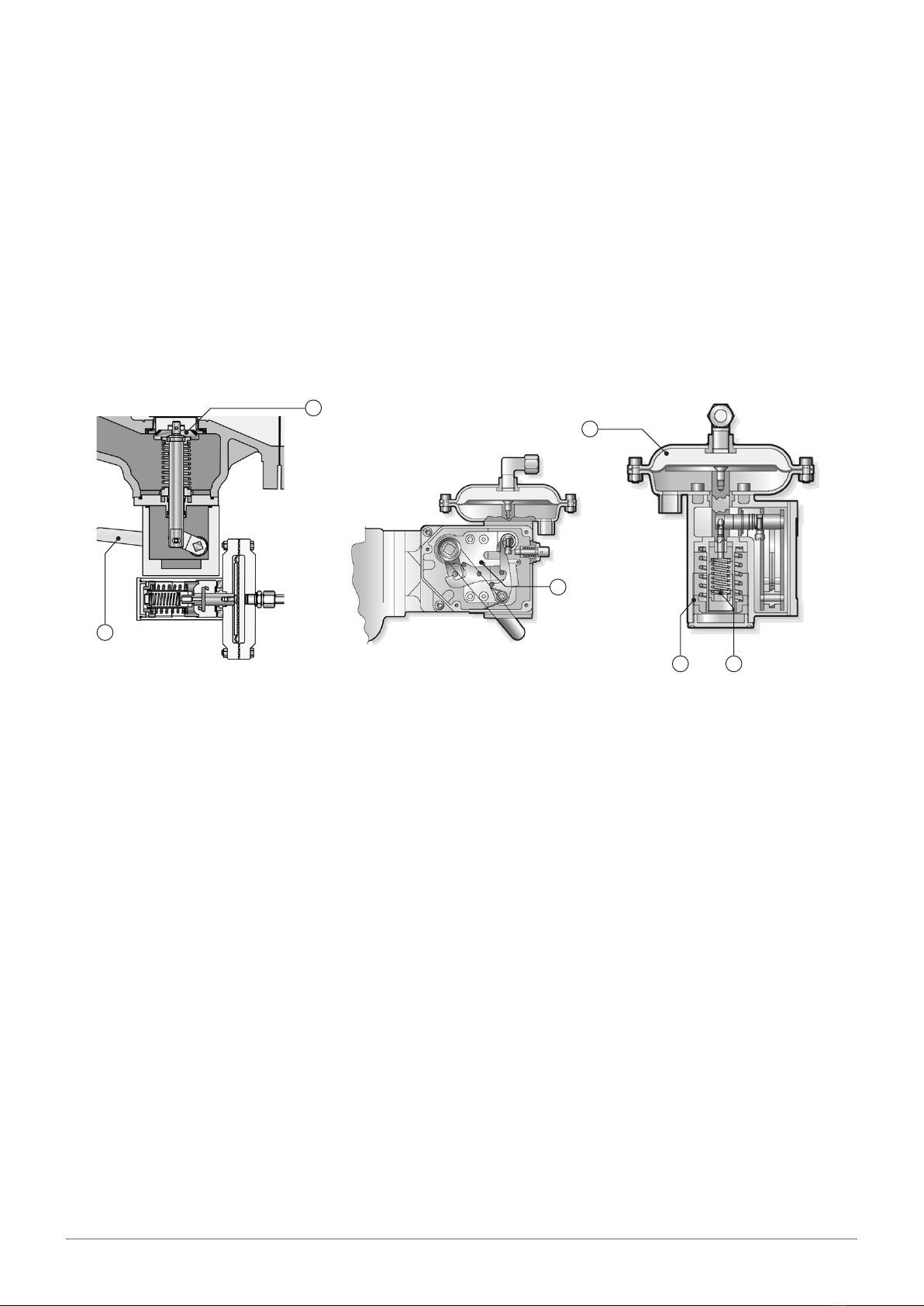

The RB 4000 pressure regulator is designed for gas supply

networks, district station regulation, industrial service

regulation, and all applications where accurate pressure

control, ease of adjustment, and fast response are re-

quired such as for burners, industrial ovens, boilers, etc.

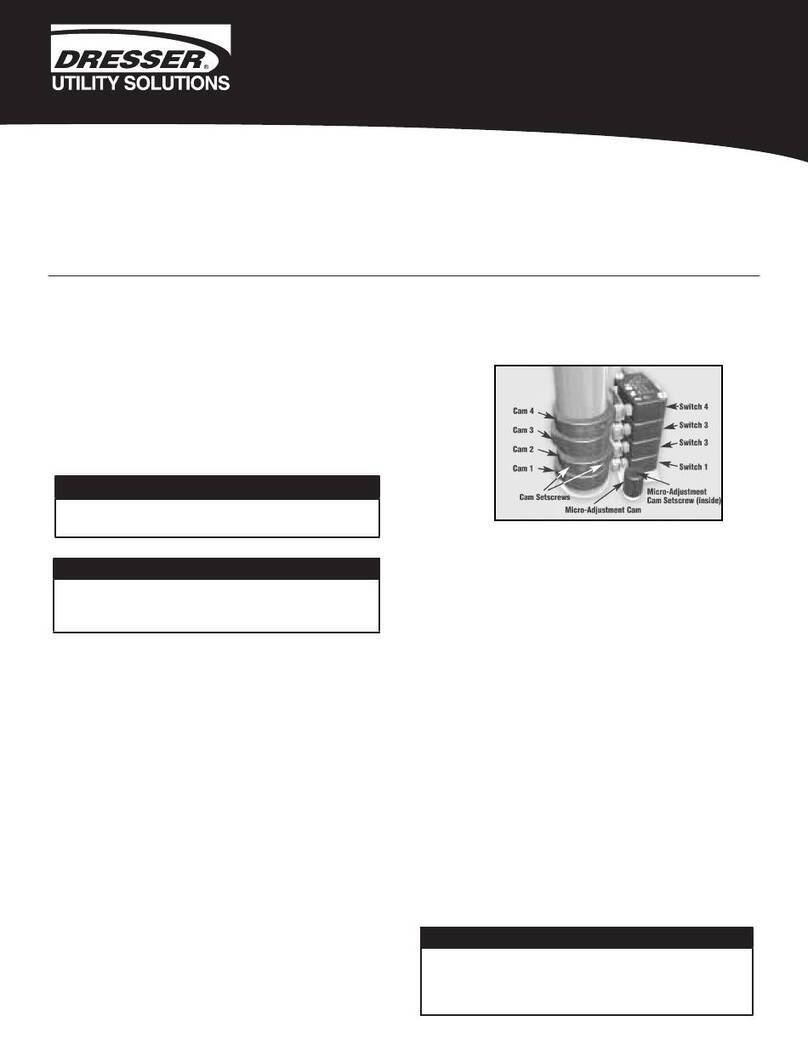

It may be tted with an integrated safety shut-o device

type SSV 8500 or SSV 8600.

Accuracy class up to AC 5

Closing pressure class up to SG10

Operating temperature -20°C to +60°C

Ambient temperature -30°C to +60°C (body material)

Allowable pressure 25 bar

Max inlet pressure 19 bar

Outlet pressure DN 25 10 mbar to 2.5 bar

Others 10 mbar to 2.0 bar

TECHNICAL FEATURES