2 OIO 14en Edition 07/2017 Operating Instructions

Table of contents

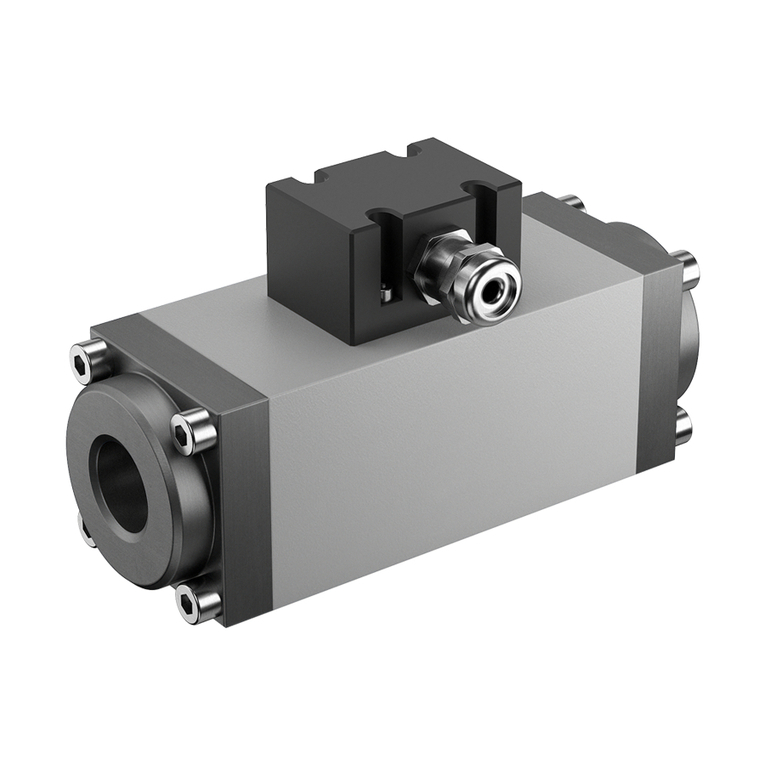

KRAL Flowmeter – OMG Series

About this document

□General information 3

□Target groups 3

□Symbols 3

□Danger levels 3

□Associated documents 4

Safety

□Proper use 5

□Safety information 5

Labelling

□Type code 6

□Rating plate 7

Technical data

□Operational limits 8

▪Load due to pressure pulsation 8

▪Maximum values 8

▪Substitute operating data 10

□Sound pressure level 10

□Dimensions and weights 10

▪OMG with BSPP thread 10

▪OMG with DIN flange 11

□Load-bearing capacity 12

▪Load-bearing capacity OMG 13 12

▪Load-bearing capacity OMG 20 13

▪Load-bearing capacity OMG 32 14

▪Load-bearing capacity OMG 52 15

▪Load-bearing capacity OMG 68 16

▪Load-bearing capacity OMG100 17

▪Load-bearing capacity OMG140 18

Heating system

□Electric heating system 19

□Fluid heating system 20

□Trace heating system 20

Function description

□Description 21

□Roller bearings 22

□Signal generation 22

□Linearization 22

□Temperature compensation 23

□Flow direction detection 23

□Junction box 23

Transportation, storage and disposal

□Unpacking and checking the state of

delivery 24

□Lifting the flowmeter 24

□Storage 24

□Preservation 25

▪Preserving the flowmeter 25

▪Removing the preservation 25

□Disposal 26

Installation, removal and connection

□Safety instructions for installation and

removal 27

□Installing the flowmeter 27

▪Installation types 27

▪Preferred installation variant 28

▪Recommendations for alternative

installation variants 28

▪Protect the flowmeter against soiling 29

▪Connecting the flowmeter to the pipe

system 29

□Electrical connection 30

▪Safety instructions for electrical

installation 30

▪Connection for the pick ups 30

□Removing the flowmeter 30

Operation

□Commissioning 32

▪Cleaning the pipe system 32

▪Checking the function 32

▪Commissioning the flowmeter 32

□Switching off the flowmeter 33

▪Safety instruction for switching off the

flowmeter 33

▪Switching off the flowmeter 33

□Recommissioning the flowmeter 33

Maintenance

□Safety instructions on maintenance 34

□Required maintenance 34

□Re-calibration of the flowmeters 34

□Mounting instructions OMG 13 35

▪Removing seals and bearings 35

▪Installing seals and bearings 36

□Mounting instructions OMG 20/32 37

▪Removing seals and bearings 37

▪Installing seals and bearings 38

□Mounting instructions OMG 52/68 39

▪Removing seals and bearings 39

▪Installing seals and bearings 41

□Mounting instructions OMG100/140 42

▪Removing seals and bearings 42

▪Installing seals and bearings 43

Troubleshooting

□Possible faults 44

□Troubleshooting 44

Appendix

□General drawings 46

□Parts list 50

□Accessories 51

▪Junction box 51

▪Mounting and connecting the

junction box 52

▪Connecting the extension cable 53

□Tightening torques 53

□Contents of the EC Declaration of

Conformity 54

□Notes 55