Table of contents

1 About this document ..................................................... 3

1.1 General information .......................................................3

1.2 Target groups ................................................................3

1.3 Associated documents ..................................................3

1.4 Symbols.........................................................................3

1.4.1 Danger levels ....................................................3

1.4.2 Danger signs.....................................................4

1.4.3 Symbols in this document .................................4

2 Safety .............................................................................. 4

2.1 Proper use .....................................................................4

2.2 Foreseeable misuse ......................................................4

2.3 Fundamental safety instructions....................................4

3 Technical data ................................................................ 5

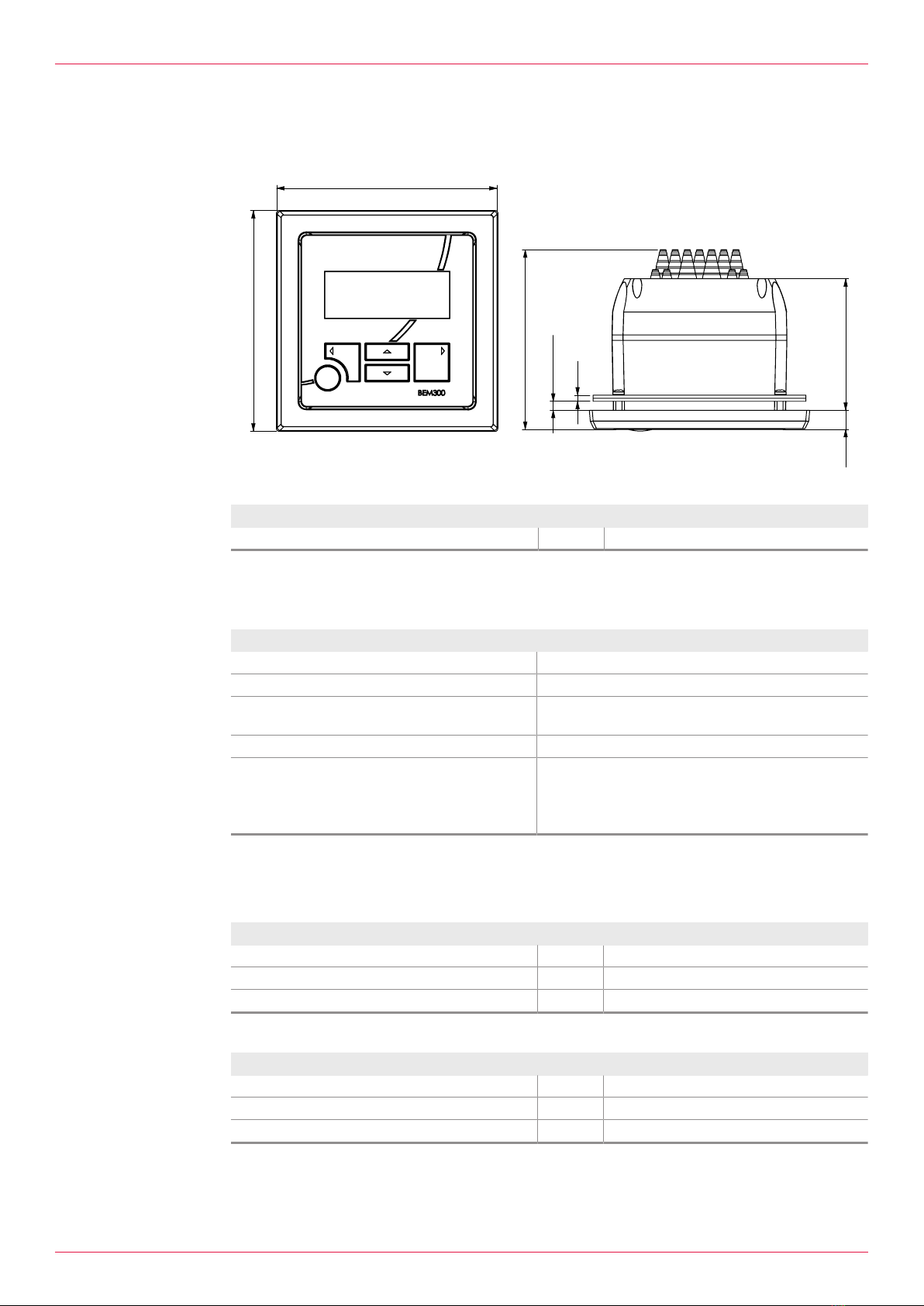

3.1 Dimensional drawing .....................................................5

3.2 Display...........................................................................5

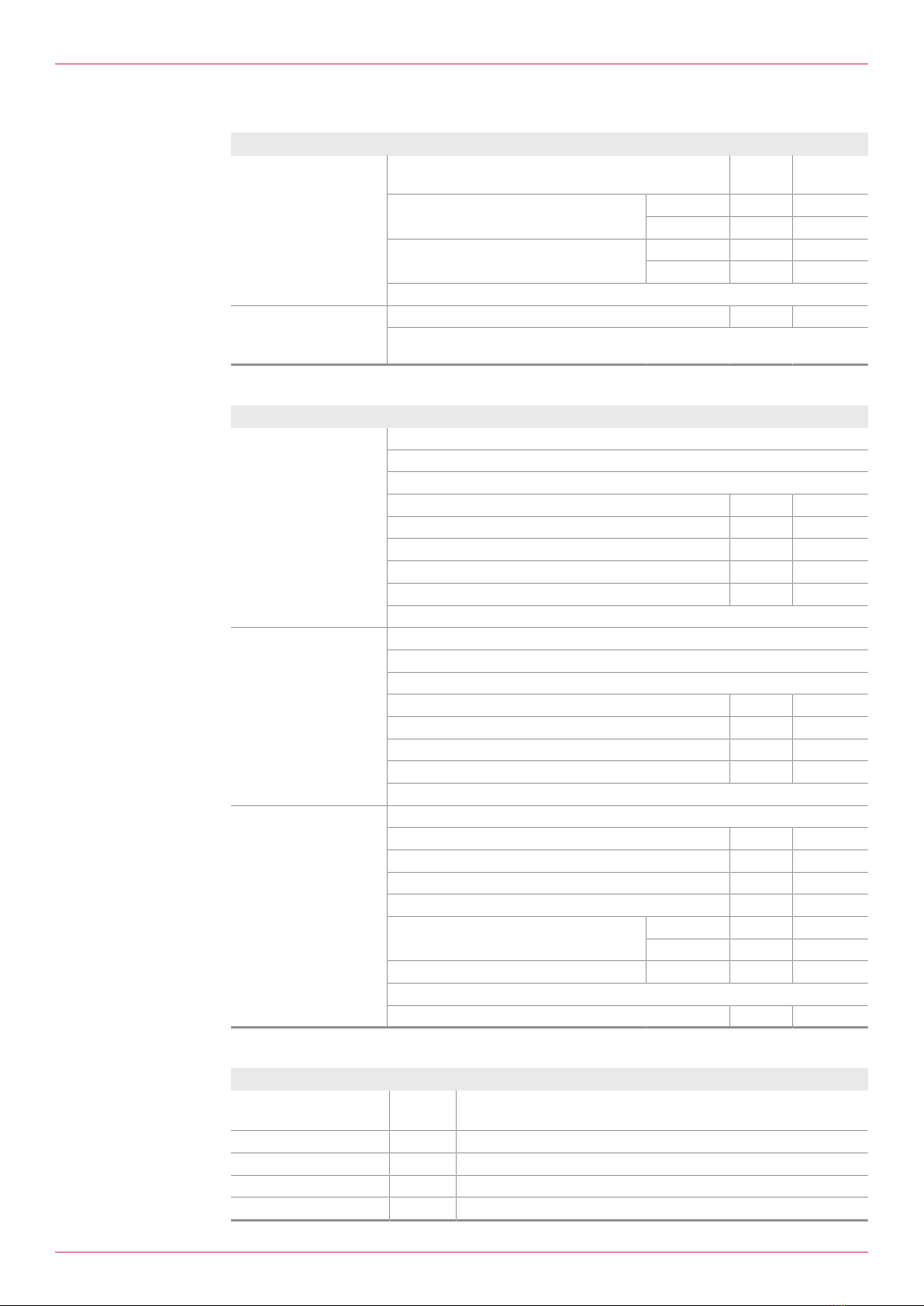

3.3 Connection data ............................................................5

3.3.1 Power supply ....................................................5

3.3.2 Tension spring terminals...................................5

3.3.3 Pulse input and analog input.............................6

3.3.4 Analog output and pulse output ........................6

3.3.5 Modbus interface ..............................................6

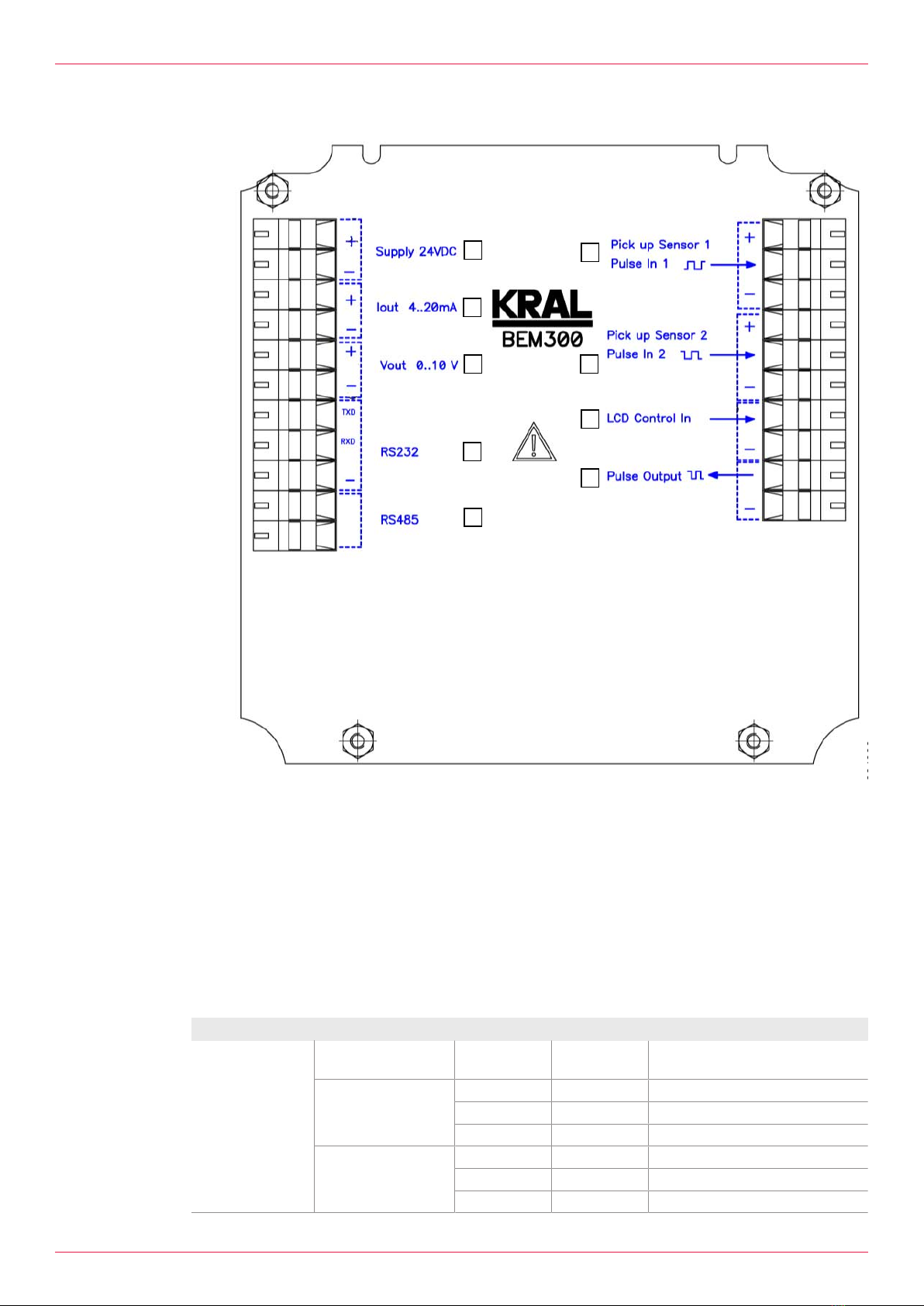

3.4 Connection field.............................................................7

3.5 Pin assignment ..............................................................7

3.6 Ambient conditions ........................................................8

3.7 Accessories ...................................................................8

4 Function description...................................................... 8

4.1 Functional principle........................................................8

4.1.1 Usage................................................................8

4.1.2 Volume measurement.......................................9

4.1.3 Mass calculation ...............................................9

4.1.4 Averaging..........................................................9

4.1.5 Flow direction detection ....................................9

4.1.6 Electronic evaluation.........................................9

4.1.7 Modbus connection...........................................9

4.1.8 Applications.......................................................9

4.2 Modbus interface .........................................................11

5 Transportation, storage............................................... 12

5.1 Scope of delivery .........................................................12

5.2 Unpacking and checking the state of delivery .............12

6 Installation, removal .................................................... 12

6.1 Dangers during installation, removal ...........................12

6.2 Installing the electronic unit in the control cabinet .......12

6.3 Mounting the electronic unit to the wall .......................13

6.4 Mounting the electronic unit at the pipe/flowmeter ......13

7 Connection ................................................................... 14

7.1 Dangers during connection work .................................14

7.2 Connecting cables to the tension spring terminals ......14

7.3 Connecting the pick up ................................................15

7.4 Connecting analog outputs and pulse inputs...............15

7.5 Connecting the power supply ......................................16

8 Commissioning ............................................................ 16

8.1 Checking the electronic unit ........................................16

9 Decommissioning ........................................................ 17

9.1 Taking the electronic unit out of operation...................17

10 Operation........................................................................17

10.1 Abbreviations, units and signals ..................................17

10.1.1 Abbreviations...................................................17

10.1.2 Units ................................................................17

10.1.3 Pulse signals ...................................................17

10.2 Key assignment ...........................................................18

10.3 Operation at a glance...................................................18

11 Menu description...........................................................20

11.1 Start .............................................................................20

11.2 Menu structure .............................................................20

11.3 Menu0: Settings (protected)........................................20

11.4 Menu 1: Display ...........................................................21

11.5 Menu 2: General settings.............................................21

11.6 Menu 3: K-factors flowmeterA.....................................23

11.7 Menu 4: Density table1 ...............................................23

11.8 Menu 7: Alarms............................................................23

12 Maintenance...................................................................24

12.1 Required maintenance.................................................24

12.2 Cleaning the electronic unit..........................................24

13 Disposal..........................................................................24

13.1 Disposing of the electronic unit ....................................24

14 Troubleshooting ............................................................24

14.1 Fault table ....................................................................24

15 Accessories ...................................................................26

15.1 Installation....................................................................26

15.1.1 Fixing kits.........................................................26

15.1.2 Universal mount fixing kit.................................26

15.1.3 Fixing kit for pipe mounting/mounting on OMG

.........................................................................27

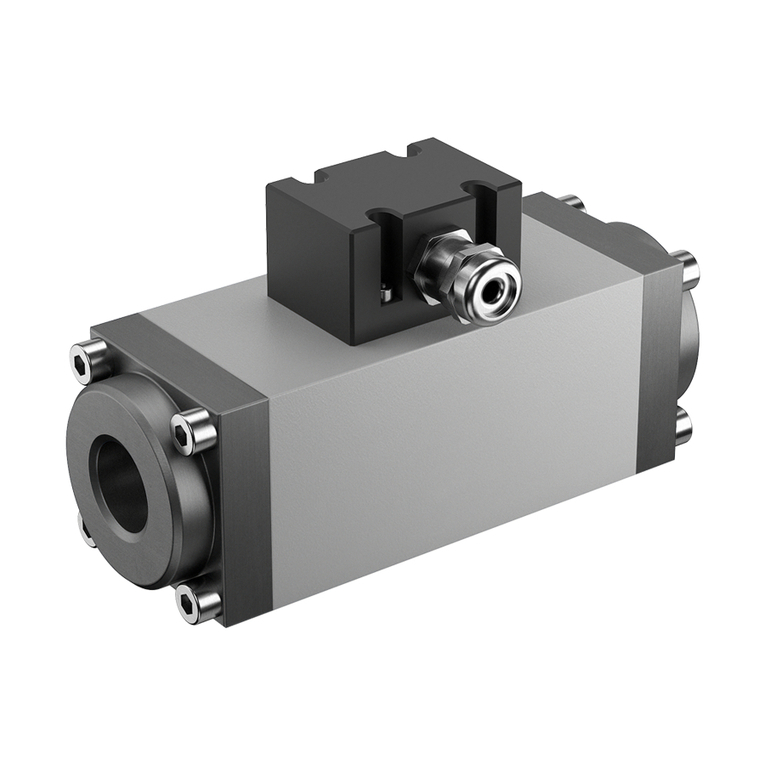

15.1.4 Fixing kit mounting on OME ............................27

15.1.5 Adapter set for conversion of BEM4U to

BEM300/BEM500 ........................................27

15.2 Electrical connection ....................................................28

15.2.1 Different voltage ..............................................28

15.2.2 Rack mounting power supply unit EEN12 ......28

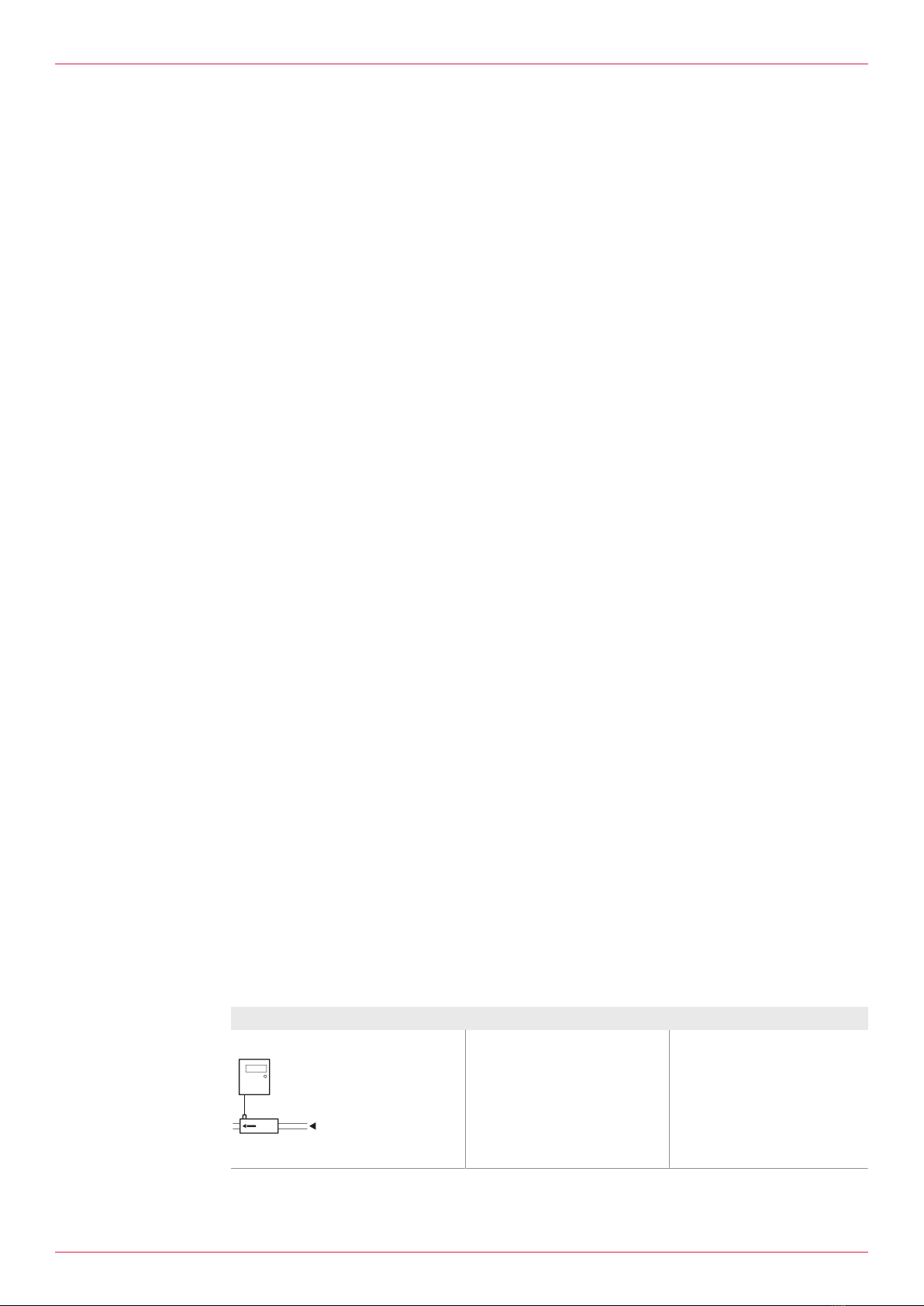

15.2.3 Plug-in power supply unit EEN13 ...................30

16 Appendix ........................................................................30

16.1 Glossary.......................................................................30

2OIE 15en-GB Edition 2020-03 Operating instructions