TOC TABLE OF CONTENTS

PQM POWER QUALITY METER – INSTRUCTION MANUAL TOC–III

5: MONITORING ACTUAL VALUES VIEWING ..............................................................................................5-1

DESCRIPTION ........................................................................................................................ 5-1

A1 METERING .....................................................................................................................5-3

CURRENT .............................................................................................................................. 5-3

VOLTAGE ...............................................................................................................................5-5

PHASORS .............................................................................................................................. 5-7

POWER .................................................................................................................................. 5-9

ENERGY ................................................................................................................................. 5-14

DEMAND ...............................................................................................................................5-16

FREQUENCY .......................................................................................................................... 5-17

PULSE COUNTER .................................................................................................................. 5-18

ANALOG INPUT .................................................................................................................... 5-19

A2 STATUS ..........................................................................................................................5-21

ALARMS ................................................................................................................................. 5-21

SWITCH STATUS .................................................................................................................. 5-23

CLOCK ................................................................................................................................... 5-24

PROGRAMMABLE MESSAGE ............................................................................................... 5-24

A3 POWER ANALYSIS .......................................................................................................5-25

POWER QUALITY .................................................................................................................. 5-25

TOTAL HARMONIC DISTORTION ......................................................................................... 5-26

DATA LOGGER ...................................................................................................................... 5-27

EVENT RECORDER ............................................................................................................... 5-28

A4 PRODUCT INFO ............................................................................................................5-33

SOFTWARE VERSIONS & MODEL INFORMATION ............................................................. 5-33

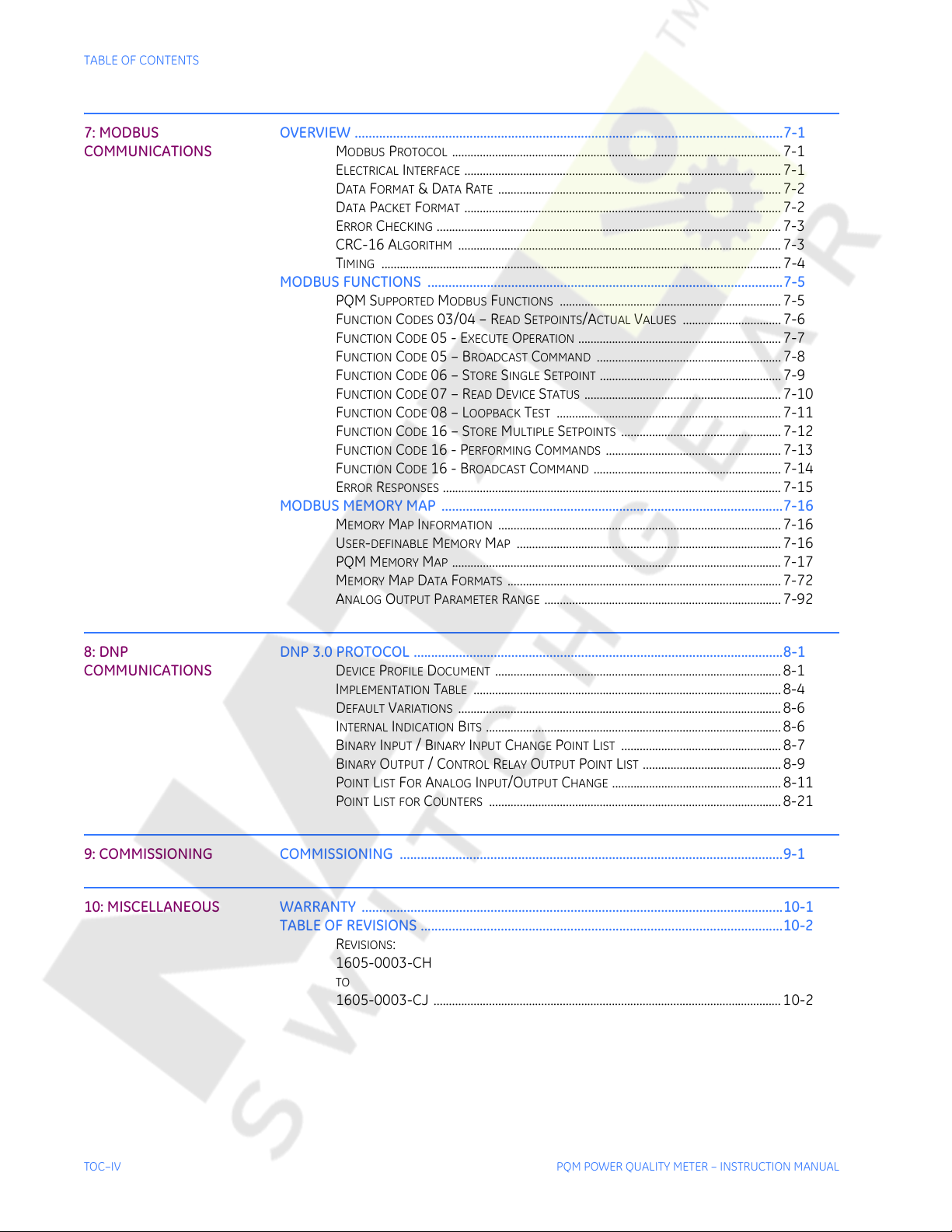

6: SOFTWARE INTRODUCTION .................................................................................................................6-1

OVERVIEW ............................................................................................................................ 6-1

HARDWARE CONFIGURATION ............................................................................................ 6-2

ENERVISTA PQM SETUP INSTALLATION ......................................................................6-4

CHECKING IF INSTALLATION/UPGRADE IS REQUIRED .................................................... 6-4

INSTALLING/UPGRADING ENERVISTA PQM SETUP ....................................................... 6-4

CONFIGURING ENERVISTA PQM SETUP COMMUNICATIONS ........................................ 6-6

ENERVISTA PQM SETUP MENUS ....................................................................................6-8

DESCRIPTION ........................................................................................................................ 6-8

UPGRADING FIRMWARE ..................................................................................................6-9

DESCRIPTION ........................................................................................................................ 6-9

SAVE/PRINT PQM SETPOINTS TO AFILE ......................................................................... 6-9

LOADING NEW FIRMWARE INTO THE PQM .................................................................... 6-9

FIRMWARE UPGRADE RECOVERY ...................................................................................... 6-11

LOADING SAVED SETPOINTS INTO THE PQM .................................................................. 6-13

USING ENERVISTA PQM SETUP .....................................................................................6-14

ENTERING SETPOINTS ......................................................................................................... 6-14

VIEWING ACTUAL VALUES ................................................................................................. 6-15

SETPOINT FILES .................................................................................................................... 6-15

GETTING HELP ..................................................................................................................... 6-15

POWER ANALYSIS .............................................................................................................6-17

WAVEFORM CAPTURE ......................................................................................................... 6-17

HARMONIC ANALYSIS ......................................................................................................... 6-18

TRACE MEMORY ................................................................................................................... 6-20

DATA LOGGER ...................................................................................................................... 6-22

Courtesy of NationalSwitchgear.com