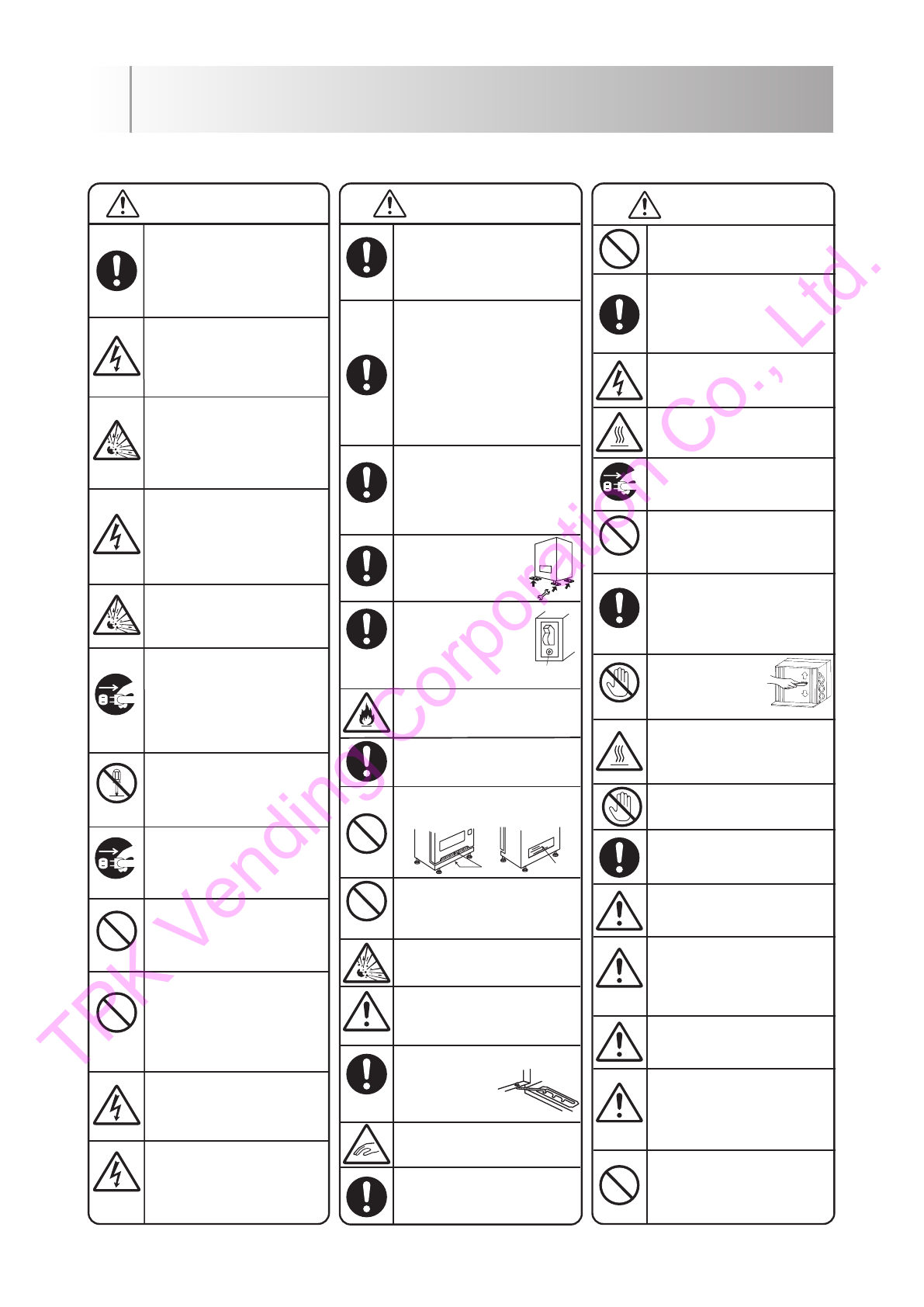

Important contents on safety. Read it carefully before using.

WARNING

Use special outlet for power, be sure

to insert the plug until it reaches the

base.Use specified power capacity.

!Extension cords and octopus

wiring may cause fires.

When leakage breaker is working, do

not switch ON, request for inspection.

!Forced Switch ON may cause

electric shock or fires.

Do not install nor use flammable

substance (e.g. thinner) or gas or

highly volatile material near

the machine.

!May cause fire or explosion.

Soda drink cannot be warmed.

!Container may burst and it is very

dangerous.

In abnormal conditions, immediately

unplug the power, and contact

professional repairers or technicians.

!Continue operating under abnormal

conditions, may cause electric

shock or fire.

Do not overhaul or repair, unless by

professional.

!May cause injury, electric shock,

or fire.

When the machine is submerged,

immediately unplug power.

!May cause fire or electric shock.

Do not use water washed electrical

components and wiring anymore.

!May cause fire or electric shock.

Store vending machine in a warehouse

and lock the vending machine and

the warehouse.

!May be used for children

playground and cause fall

accident.

Do not operate electric plug and

switch using wet hands.

!May cause electric shock.

During product replenishment on

rainy or snowy days, beware not to

make internal electrical components

wet.

!May cause electric shock.

Do not modify, pull, place heavy

object on top, or damage the

power code.

!May cause fire or electric shock.

Clean and renew the warning

indication in order to be able read it

correctly.

!May cause accident if it can not be

read correctly.

When installing on the following

locations, discuss first with the fire

department.

!Get in the way of traffic or disaster

prevention

!

Around the fire extinguishing facilities

!

Area that handle flammable materials

or gas

!Gasoline station

!Passage and facilities for evacuation

When installing on the following locations,

discuss first with the supplier.

!Area exposed to briny air & corrosive

gases

!Area with great amount of shakes

and vibrations.

Regularly inspect installation

surface and its brackets.

!Incomplete installation

may cause fall accident.

Check operation of leakage

breaker more than

1x/month by pressing

the test button.

!Abnormal operation may

cause electric shock

Periodically clean the power plug, and

insert plug until it reaches the base.

!

Dust on the poor merge may cause fire.

Use only specified voltage and frequency.

!Operating under unspecified voltage

and frequency may cause accident.

Don’t block air inlets and outlets.

!

Poor ventilation may cause

accident.

Keep heating device away from the

power cord.

!May cause fire, electric shock if the

cord melts.

Use products without contents for display.

!

May explode as temperature increase,

and cause injury.

Be careful of passers or vehicles when

opening the door.

!May cause accident by passers or

vehicles.

When the opening the door,

fix it not to close.

!May cause injury

if the door suddenly

close due to wind.

When opening and closing the door,

be careful of fingers.

Test button

Load only the given products.

!Loading unspecified product may

cause accident.

CAUTION

This machine is designed for domestic

use only. Do not use in foreign country.

!Due to difference in voltage, may

cause fire, smoke, or burnout.

When disposing the machine, delete

device features for notes, cards,

coins identification.

!May cause criminal fraud and

forgery.

Do not look straight in to the LED

lighting for long time.

!May have bad effect on your eyes.

Do not load leaked or deformed products.

!May cause accident.

Use protective gears (gloves, long

sleeves) when touching column or

detaching components, except for

product packing or column setting.

!May cause injury.

㩷

Turn power off when replacing

fluorescent tubes(LED lamp).

!May cause electric shock.

Replace fluorescent tubes (LED lamp)

after cooling down.

!May cause burning.

Turn power off during cleaning and

inspection.

!

May cause electric shock and injuries.

During maintenance, do not apply water

directly by water hose or bucket.

!

May cause electric shock or

machine failure.

While cleaning the condenser, when

opening the cover, do not touch

the edges, use the holes on the left

and right side.

!May cause injury.

While cleaning the

condenser, do not touch

the fins.

!May cause injury.

Do not touch the delivery chute, when

compartment is heated.Turn off power,

wait untill it cools down.

!May cause burning.

Don’t touch moving part.

!May cause injury.

Destroy the key when disposing the

machine.

!May cause abuse.

When disposing the machine, Fluorescent

tubes, Freon, nickel-cadmium batteries

must be disposed of in accordance with

the prescribed method.

!

May cause environmental destruction

While cleaning the front panel and

display, beware of the projections.

!May cause injury.

CAUTION

1 SAFETY CHAPTER

- 2 -

Inlet outlet

TPK Vending Corporation Co., Ltd.