2 / 12 Service Manual for KEA 201 ERSY –File: SA_KEA 201 ERSY_EN_Ver 2016-07-01.doc 2 / 12

Changes without further notice

reserved.

An der Kleinbahn 39, D-21423 Winsen (Luhe)

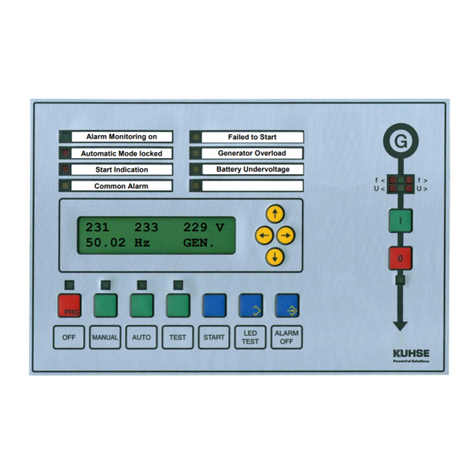

1.2. Analogue Readouts

Actual values:

-Voltages

-Currents

-Active and apparent load

-Power factor

-Speed

-Battery voltage,

-Actual values of the four analogue channels

-Actual status of the digital inputs of the relay unit RZ 071-D

-Actual status of the output relays

Timers' status.

2. Amendments

- Technical Data: Corrected: Optical fibre or USB interface –with automatic switching –

for parameterisation 2. Removed: Option in preparation: GSM modem

- Last page: Added: Drilling Template, Scale 1:1 (was down-scaled before)

3. Contents

1. Design ..................................................................................................................................... 1

1.1. Parameterisation ...................................................................................................................... 1

1.2. Analogue Readouts................................................................................................................... 2

2. Amendments ........................................................................................................................... 2

3. Contents .................................................................................................................................. 2

4. Safety Instructions ................................................................................................................. 3

4.1. Regulations and Instructions ..................................................................................................... 3

4.2. Installation and Commissioning ................................................................................................. 3

4.3. Connections ............................................................................................................................. 3

4.4. Battery and Supply voltage ....................................................................................................... 3

4.5. Inductors ................................................................................................................................. 3

5. Connections............................................................................................................................. 4

6. Operating the Display ............................................................................................................. 5

7. Setting the Display Contrast ................................................................................................... 5

8. PIN Number, Ident-Number ................................................................................................... 5

9. Parameterisation Menu structure ........................................................................................... 6

10. Connections on Relay Unit RZ 071-D ...................................................................................... 6

Terminals 1–14: Input for alarms signals. .................................................................................................................. 6

Terminal 15: Feedback signal: MAINS IS OFF. ............................................................................................................... 6

Terminal 16: Feedback signal: GENERATOR IS OFF. ........................................................................................................ 6

Terminal 17: Operation mode selection is locked. .................................................................................................... 6

Terminal 18: Remote start with load transfer. .......................................................................................................... 6

Terminal 19: IMMEDIATE STOP....................................................................................................................................... 7

Terminal 20: Overlapping synchronisation active...................................................................................................... 7

Terminal 21 ................................................................................................................................................................ 7

Terminal 22 ................................................................................................................................................................ 7

Terminal 23: Sprinkler mode...................................................................................................................................... 7

Terminal 24: Start enable input. ................................................................................................................................ 7

Terminal 25: Remote start without load transfer. ..................................................................................................... 7

Terminal 26: External command :GENERATOR OFF........................................................................................................ 7

Terminal 27 ................................................................................................................................................................ 7

Terminal 28 ................................................................................................................................................................ 7

Terminal 29: Charging Dynamo, terminal D+............................................................................................................. 7

11. Technical Data......................................................................................................................... 8