G-17, Bharat Industrial Estate, T. J. Road, Sewree (W), Mumbai - 400 015. INDIA.

Sales Direct.: 022 -24156638, Tel. : 022-241224540, 24181649, Fax : 022 - 24149659

An ISO 9001:2008 Company

®

All Specifications are subject to change without prior notice

Navin.com/D.drive/sandeep gupta/New catlog Dec 2011/ 500HP.cdr275HP-

An ISO 9001:2008 Company

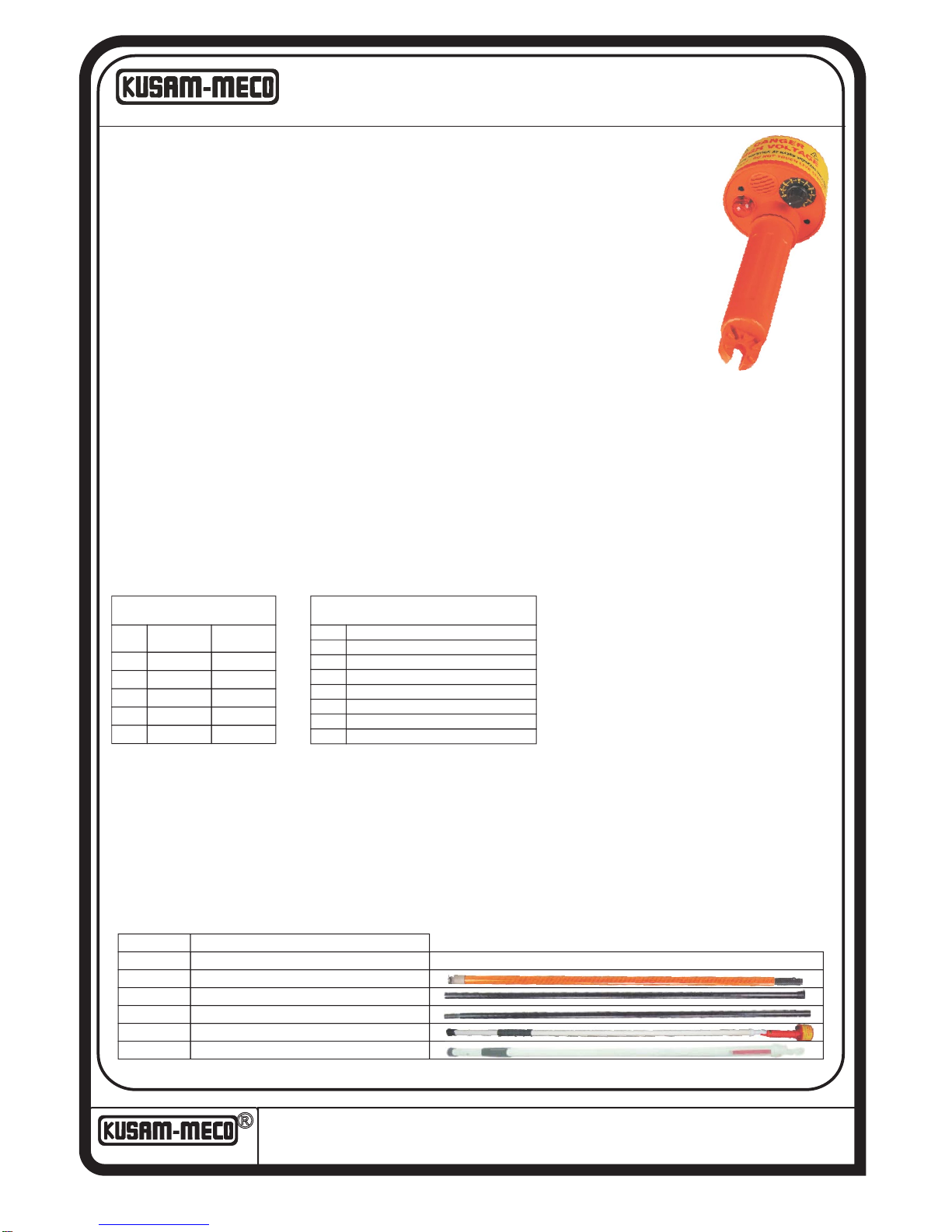

®HIGH VOLTAGE PROXIMITY DETECTOR

Model 275 HP (Upto 275KV) / 500 HP (Upto 500KV)

The 275HP / 500HP is a HIGH VOLTAGE proximity detector. 275HP has eight voltage detection settings from 240Vac to 275KVac. & 500HP

has 10 Voltage detection settings from 240V to 500KV. The 275HP / 500HPconsists of an internal pickup sensor plate, a sensitivity selector,

a visual and a sound annunciator. With the 275HP / 500HP physical contact with electrical conductors is not necessary when testing for live

lines. This tester works by proximity.

Checking or proofing the tester is easy. Switch the sensitivity to 240V AC and place the dome against a low voltage live conductor or rub the dome with a cloth or

against an item of clothing as this generates a static DC which triggers the detection of circuit. The light and beeper should go “on” as if a live wire is being approached.

Approaching the dome near a computer screen or a TV screen (not liquid crystal display type) should also trigger the tester while on 240V selection.

Its sensor senses the radiated field which surrounds live conductors. Radiated field strength increases with voltage & decreases quickly with

distance or earth shielding. The radiated field from a cable of closely bunched conductors supplied by three phase power tends to cancel

(See “Limitations of use” paragraph). Detecting distance of a 250Vac single live wire is approximately 10cm. With a bunched neutral and

earth cable, as in a flexible cable, the distance is reduced to 5cm.

Some of the typical users are : identify and check live cables; find fault in flexible cables; check earth equipment; service neon lightning;

trace live wires; check high frequency radiation ; detect residual or induced voltages. For example, faults in damaged flexible cables are

found by applying low voltage to each conductor. Earthing the remainder and moving the tester along the cable until the change in condition

is obtained. (Flexible cables which are used in mining and building industries, are readily repairable when the break in the cable is located.)

When using for high voltage, the rotary switch (attenuator) is used to identify and differentiate various HV live cables. The tester must be

used in conjunction with a long and insulating rod when measuring high voltage (KV). However, the 275 HP / 500HP is a non contact

tester and it is advised that the tester should never come in to contact with cables (KV) as this tester is merely a non-contactAC proximity

tester.

FEATURES :

SAFETY:

?Meets EN61000-3-2; EN61000-3-3; EN61326-1; EN55011 EN61000-4-2; EN61000-4-3; EN61000-4-4; EN61000-4-5; EN61000-4-6; EN61000-4-11.

Typical observation of test

results made in the fields

11KV

22KV

33KV

132KV

275KV

Range MinDetection

Voltage (MDV)

MDV as % of

Line Voltage

1KV

2KV

3.1KV

12.5KV

22.5KV

9.1%

9.1%

9.4%

9.5%

8.2%

Expected test results

(laboratory testing):

Range Operated From

240V

2KV

6KV

11KV

22KV

Variable from 80V or depending on the type of source

250V

500V

33KV

132KV

1000V

1500V

4000V

8000V

LIMITATIONS OF USE :

It is recommended that the 275HP / 500HPis not used in HV yards of mixed voltages. In the presence of mixed voltages, the tester can become unreliable.

Problems can arise when the tertiary circuit of a 275/133/11KV transformer is tested. The electric field of the HV and MV bus bars can trigger the detector when it is

above 3m above the ground. This is common with most of the electric field voltage detectors, and the users should be aware of it. The tester can pick up adjacent

circuit to the one being tested and indicate the wrong information to the user.

8 Voltage Settings : 240V , 2KV, 6KV, 11KV, 22KV, 33KV, 132KV and 275KVAC (Model 275HP).

?10 Voltage Settings : 240V, 3.3KV, 11KV, 22KV, 33KV, 66KV,110KV, 220KV, 330KV, 500KV (Model 500HP).

?Self test selection.

?High bright LEDs visual indication.

?Sound indication.

?

?Non-contact work by proximity.

?Detect low voltage on any systems.

?Compatible with most link sticks.

?Use 3 x 1.5V “C” batteries

?Easy access to batteries.

?High impact nylon casing.

?Sealed by “0” rings

?Suitable for indoor and outdoor use.

?Light weight, robust, & compact.

?Weight :Approx. 500g.

The distance for detection of the voltage depends upon the

range selected & actual Voltage of the conductor.

e.g. If the range selected is PC11KV, the minimum distance for

detection of the PC11KV voltage is 22cm. But if the range

selected is PC22KV, you need to be closer (14cm) to detect

the PC11KV conductor.

HOT STICK Model HSR - 120 / 120A / 120B / 120C / 121 / 122

“KUSAM-MECO” Hot Stick is suitable for use with Non Contact High Voltage Detector Model 275HP & 500HP. It’s construction is Telescopic. It is constructed from

highly insulating reinforced Fibre Glass rod. The reinforcement gives high mechanical strength. It has a rubber gripper for holding it firmly when making

measurements of H.T. Lines. It is supplied with carry bag.

Model Length

HSR 120

HSR 120A

HSR 120B

HSR 120C

HSR 121

HSR 122

1 x 1.2m Orange stick & 3 x 1.8m Black stick.

1 x 3.0m Retractable stick.

1 x 5.0m stick.Retractable

1 x 1.2m Orange stick

1 x 1.8m Black stick

1 x 1.8m Black stick with handle

Combination of 3 Models Sticks HSR 120A, 120B & 120C