4

1. Unpacking

Open the box carefully and remove the top covers.

First remove the armbase and prepare it for fixing onto the turntable. Be sure that the

armboard on the turntable has the correct cut-out (main central hole must be 40 mm in

diameter).

2. Basic set up

Armbase:

Mount the armbase on the turntable. If the pre-cut has a thread, then use three screws and fix

them from the top through the armbase into the armboard thread. A second way is to use a

ring underneath and fix three screws into this ring, which will then hold the armbase very

tightly. Be sure that you position the armbase so as to give access to an Allen key for fixing

arm into the armbase (towards the back of the turntable). Also check, when mounting the arm

on other turntables, that you allow enough clearance for counterweights and correct position

of the tube in relationship to the platter.

VTA arm tower:

Insert the VTA arm tower into the armbase. Ensure that the height is such, that the bottom

surface of the platform holding the cueing device is at the same height as the record. Fix it

with an Allen key. Also check that the VTA adjustment is in the middle position, to allow fine

VTA adjustment up and down 5 mm each way.

With 1.5 mm Allen key, release the small ring which is on the fixing pillar below the VTA

arm tower. Now it will drop down and touch the armbase. Fix the ring again and release the

VTA arm tower. You now have the correct height but you can freely rotate the VTA arm

tower horizontally. Rotate it to such a position that the distance from the centre of the record

to the centre of the horizontal bearing is 300 mm. Now fix VTA arm tower.

3. Setting up the tonearm

Connecting tonearm:

Check the horizontal movement of the tube to ensure that the headshell will reach the inner

grooves.

Due to the high tonearm mass, turntable levelling and suspension should be checked and

adjusted according to the turntable manual.

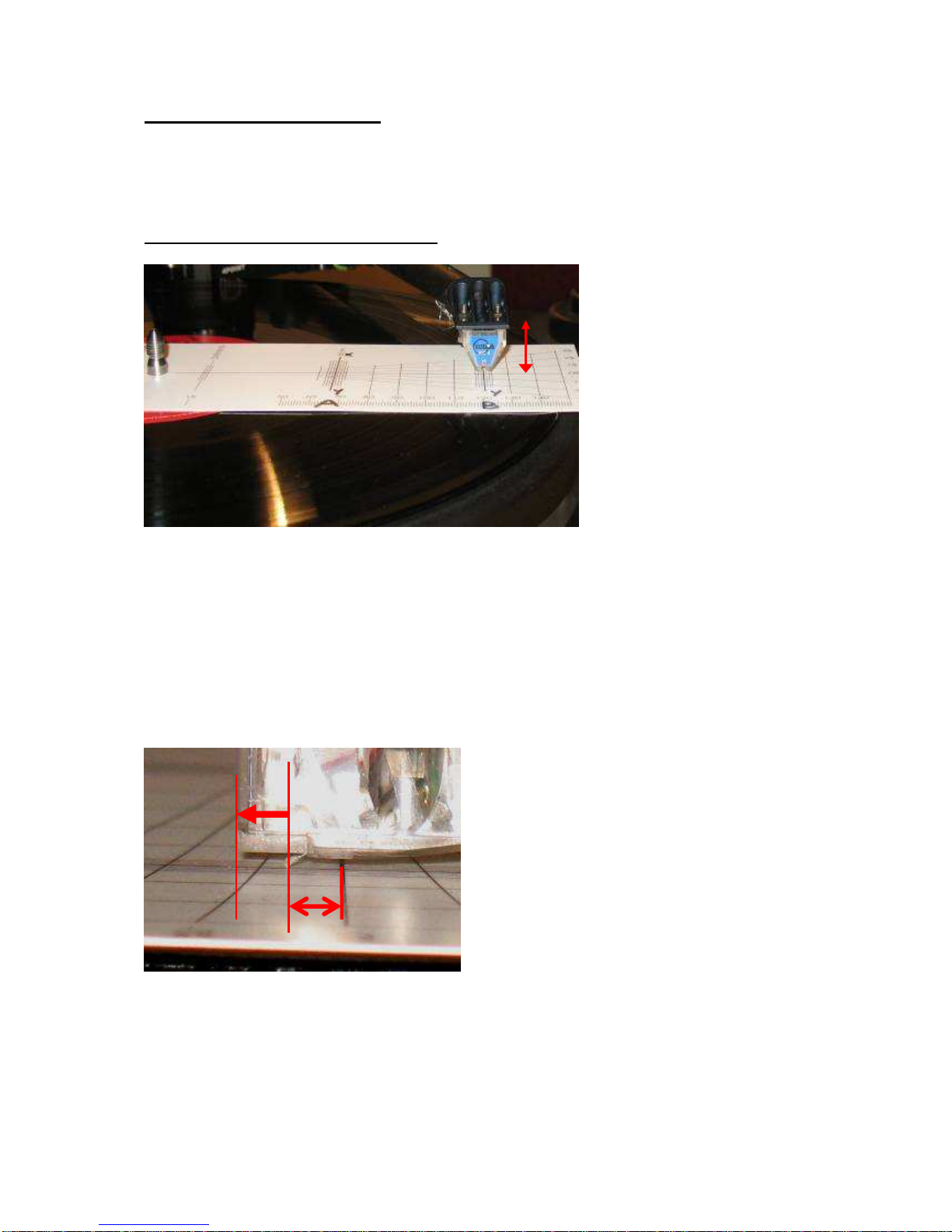

Cartridge mounting:

Mount the cartridge with the appropriate set of 2.5 mm screws and check its travel above the

record with cueing device in upper position!