moving the cartridge in the grooves. Of course this also happens in pivoted

arms but due to differences in construction ie. loose bearings vibration of

bearings and other parts.

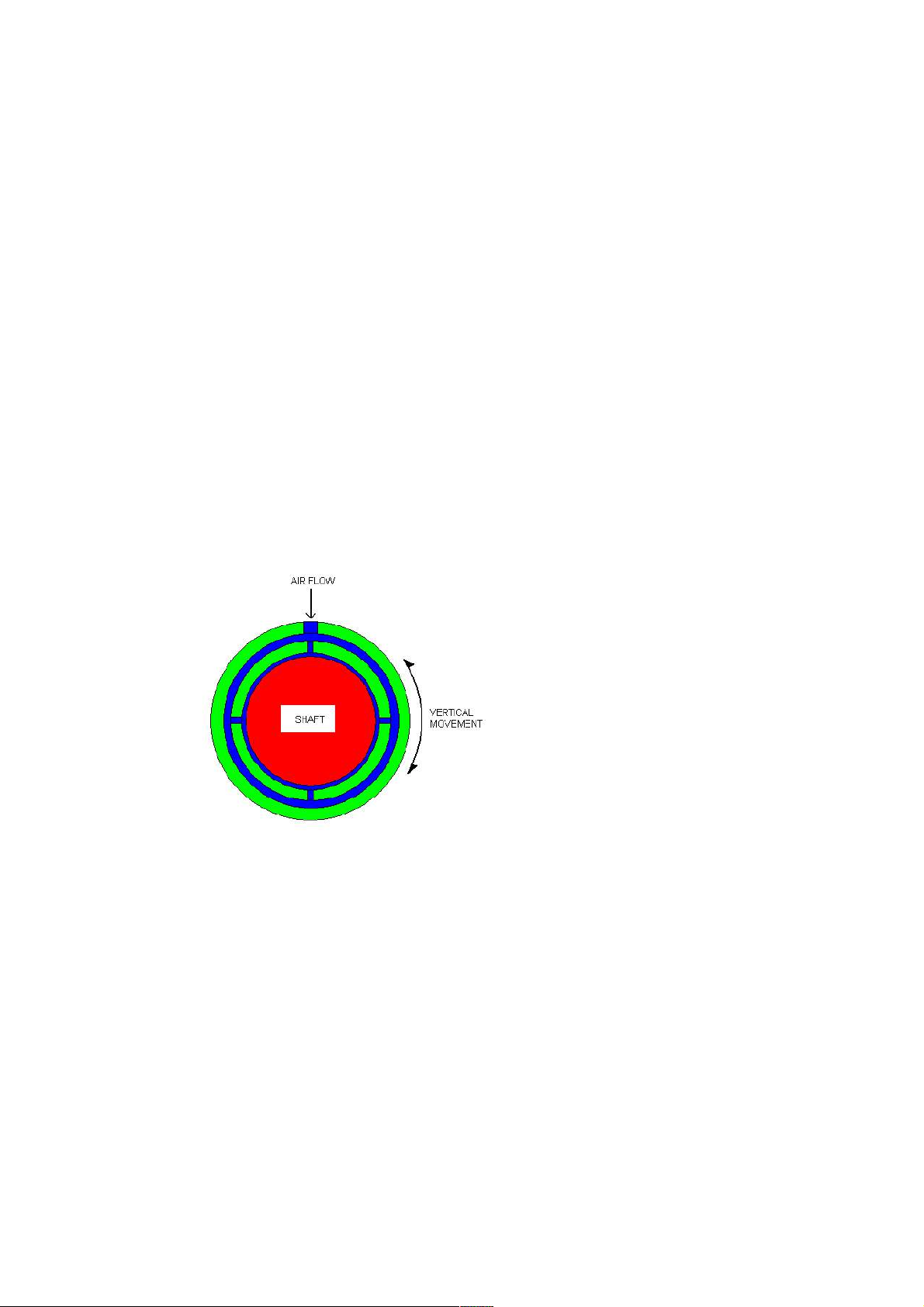

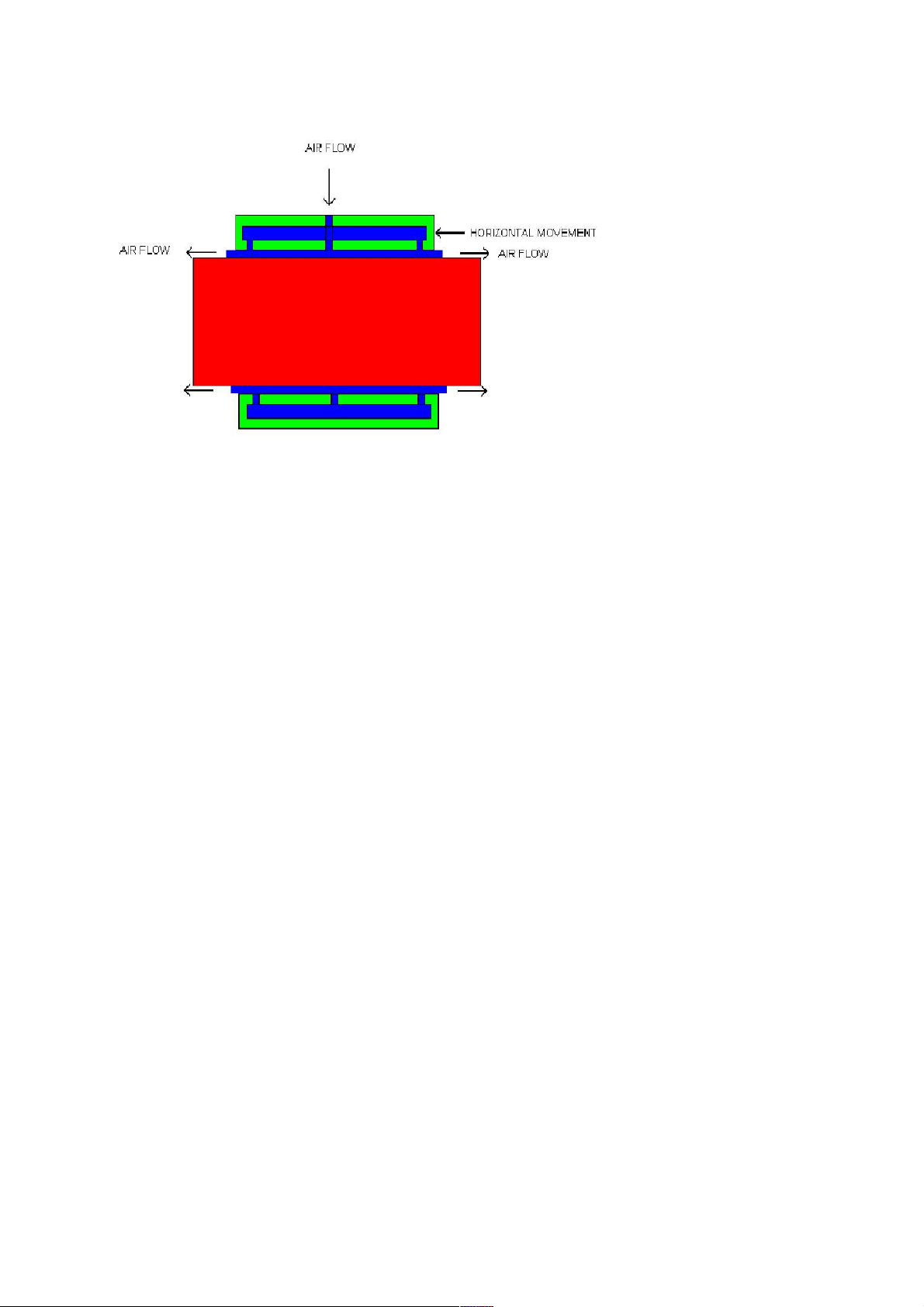

To practically avoid this effect we must use a stiff bearing which automatically

reacts to these external forces. Construction of a stiff airbearing is dependent

on the air gap air pressure and bearing surface. Higher air pressure means a

stiffer bearing which can carry a heavier load. The same effect can be achieved

by a small air gap between the moving parts of the bearing. In the best bearings

the gap is limited to a construction of 10 microns. This is actually less than in

most pivoted tonearms which have air slack in their bearings to move!!

A stiff bearing will not in itself stop the tonearm bearing from moving closer to

one side of the bearing shaft when force is applied to one side. The bearing

must be constructed in such a way that it is self-centering. That means in

practice if force is applied to one end the gap will decrease but a properly

constructed bearing will respond to this by increasing airflow to the smaller

gap restoring the equilibrium.

In practice the gap stays the same if forces are not overloading the bearing and

the cartridge position under dynamic conditions remains stable. If we apply

force to one end of the bearing sleeve we have the same problem. To have a

self-centering effect along the axis as well as along the diameter of the rod the

airbearing must be properly designed.

An airbearing has few holes through which air is forced but most such bearings

behave poorly under dynamic conditions. If the bearing were to have only a

few holes then the bearing would twist moving the cartridge away from a

tangential line.

The best solution is an almost infinitessimal number of holes which can be

obtained by use of porous material with holes of 10-20 microns in size. This

makes the most stable bearing and in our case forces equivalent to a few kilos

applied to the tonearm will maintain the gap as a stiff bearing with practically

zero friction.

Another positive aspect of the tangential tonearm is its lack of bias forces.

Close inspection shows that the forces pulling the cartridge along the groove are

dependent on the modulation of the groove the flatness of the record and the

eccentricity of the grooves. In a tangential tonearm all these forces are pulling

straight forward along the tube and the cartridge can not move along the axis of