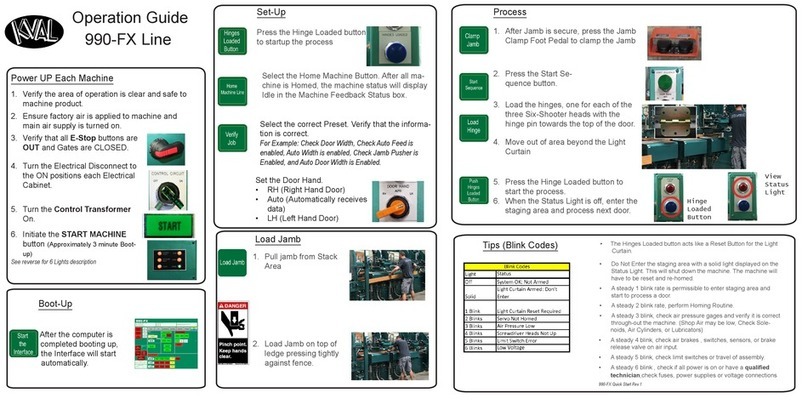

KVAL 990-FX Operation Manual

Hinges Loaded Button (Light Curtain Status Light)...............................2-9

Safety Controls ........................................................................ 2-10

Emergency Shutdown and Recovery .................................................2-10

990-FX Light Curtain...........................................................................2-10

If the Beam is Broken .........................................................................2-10

To Resume Normal Operation after an Beam is Broken.....................2-11

Air Brake on 990-FX Six Shooter........................................................2-12

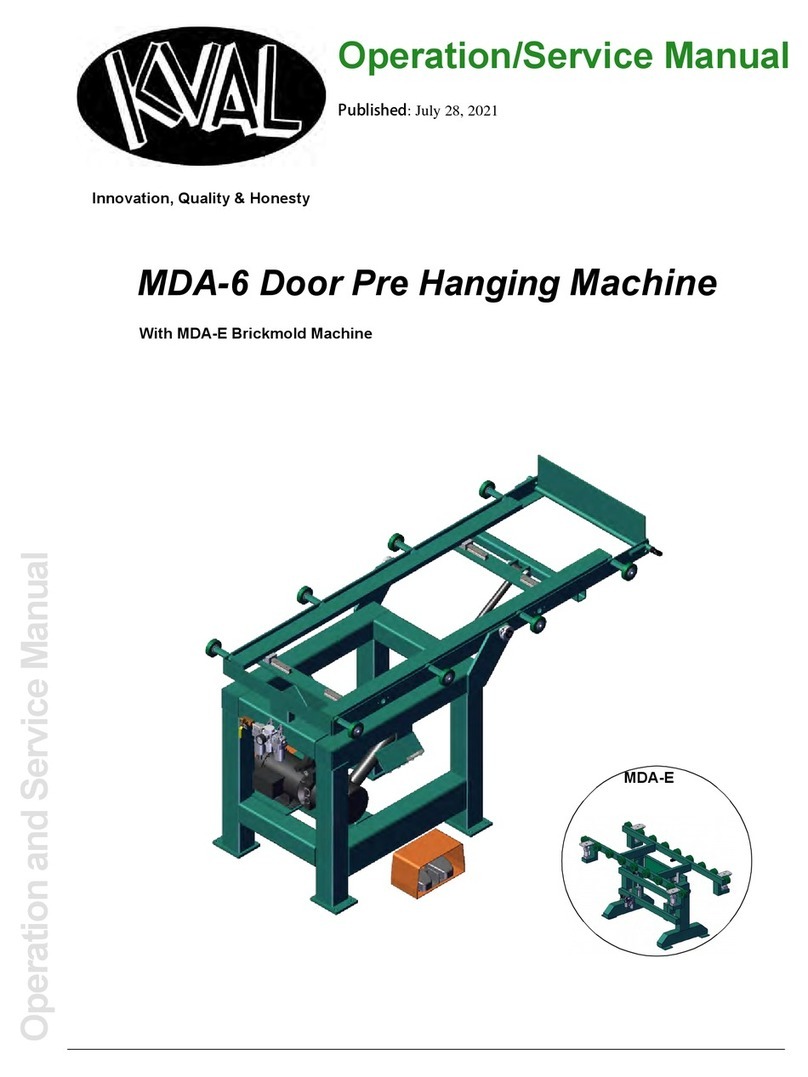

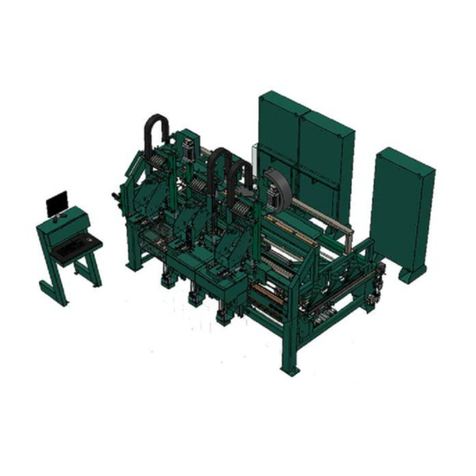

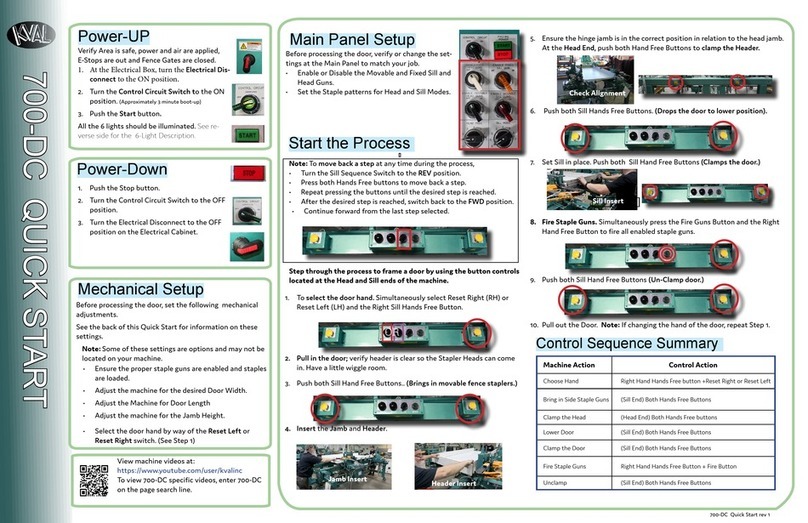

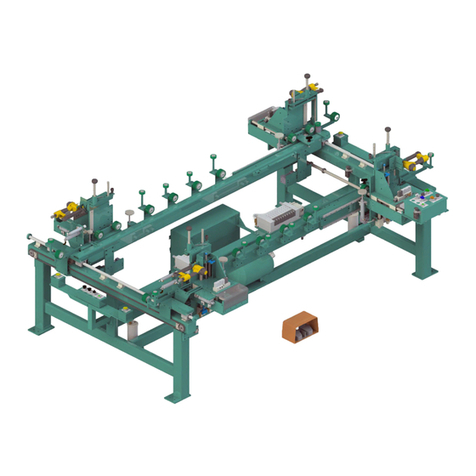

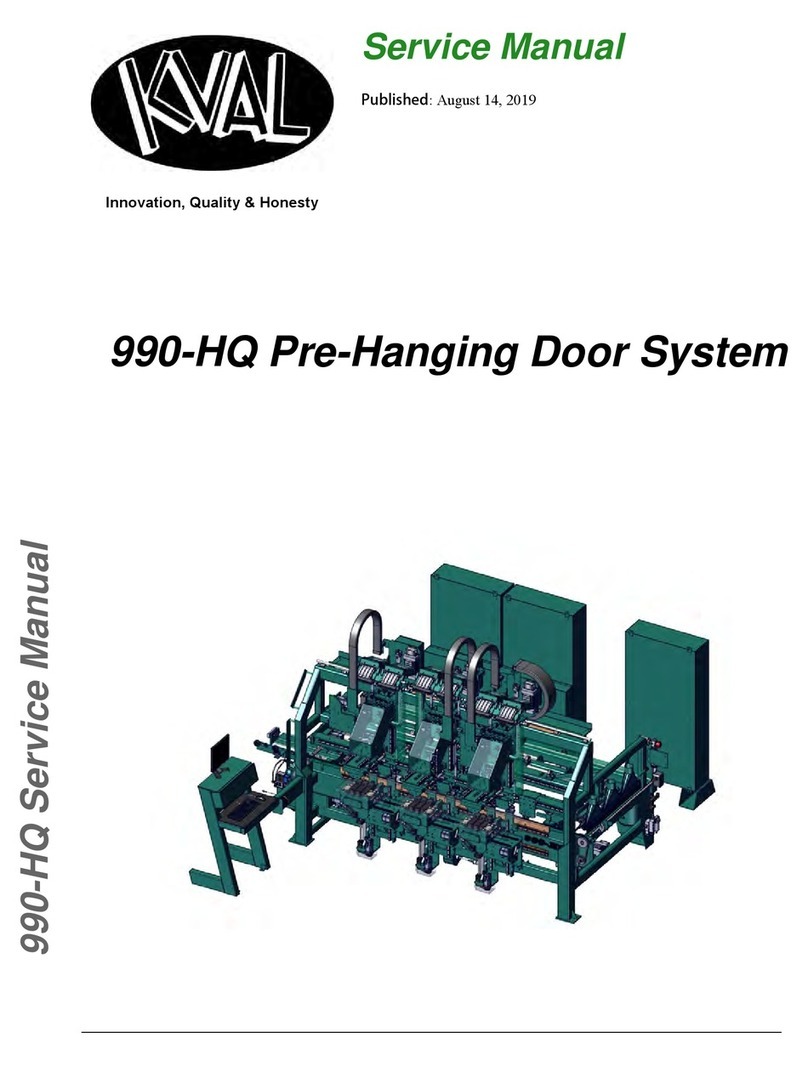

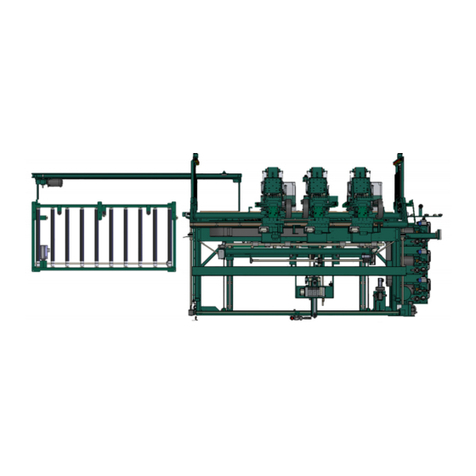

Tour of the Machine ................................................................2-13

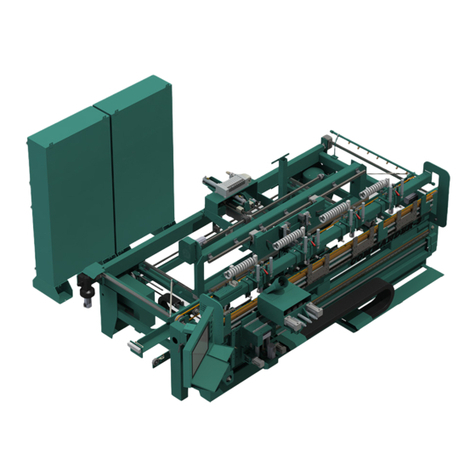

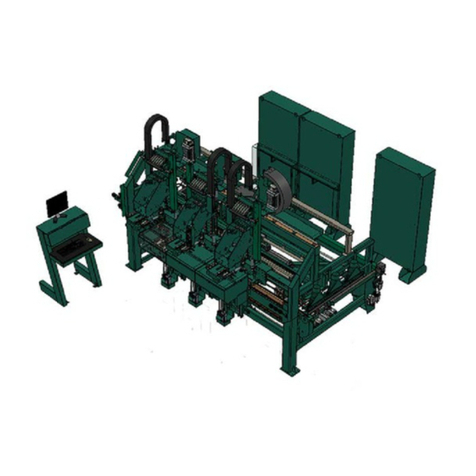

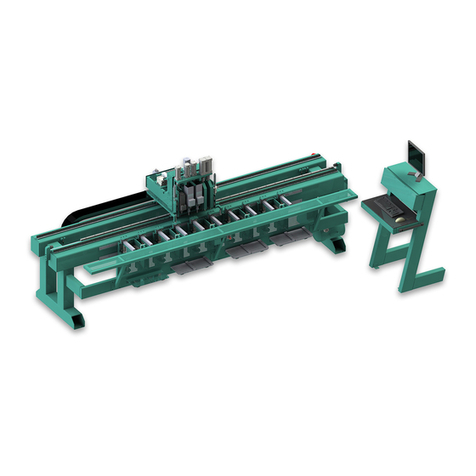

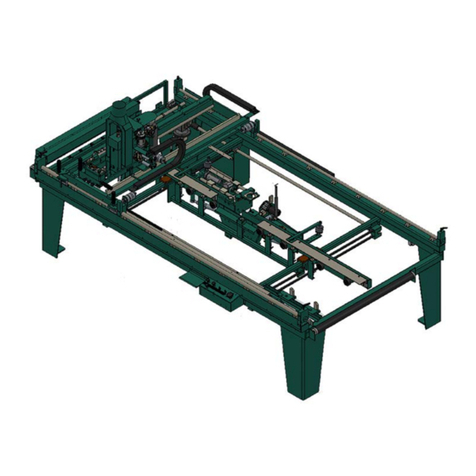

About the In-Feed Section ..................................................................2-13

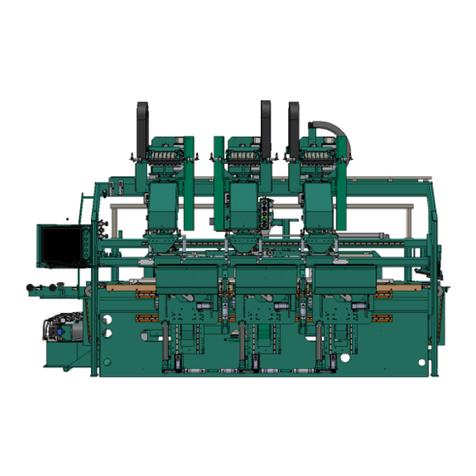

About the Front Section......................................................................2-14

About the Hinge Carriage ...................................................................2-15

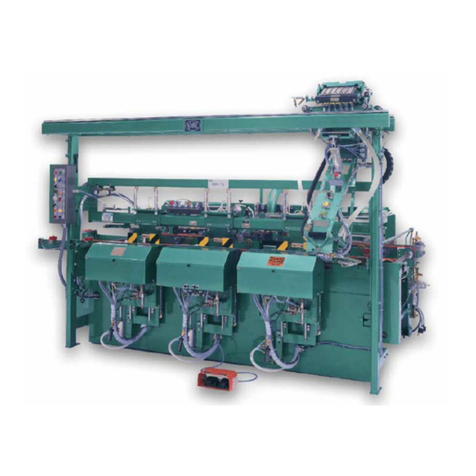

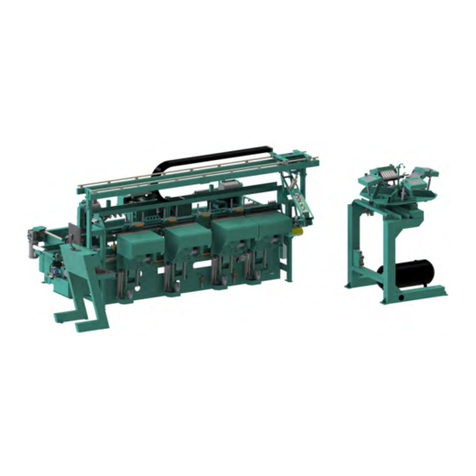

About the Six Shooter System............................................................2-16

About the Six Shooter Assembly ........................................................2-18

Driver Assembly..................................................................................2-19

About the Back Section ......................................................................2-20

Back View of Rear Section .................................................................2-21

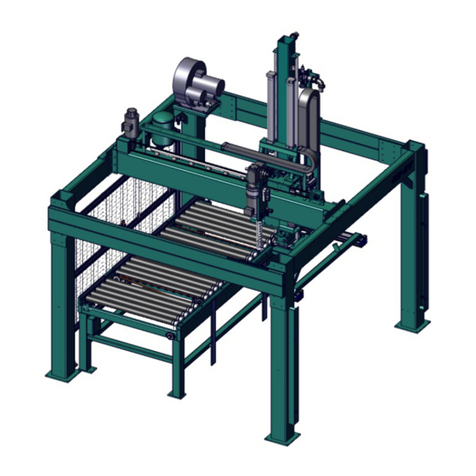

About the Out-Feed: ...........................................................................2-22

About the Electrical Panels.................................................................2-23

Description of the Six Light Panel ........................................... 2-25

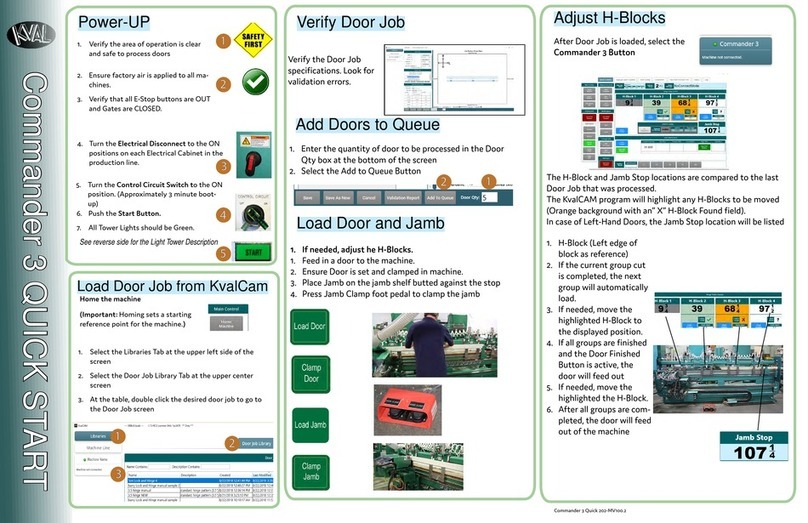

Machine Start Summary .......................................................... 2-26

Initial Powering Operations for the 990-FX Line ...................... 2-29

How to Power Up the Line ..................................................................2-29

Home the 990-FX ...............................................................................2-30

How to Power Down the Machine.......................................................2-31

Emergency Shutdown and Recovery .................................................2-31

To Resume Normal Operation after an E-Stop ...................................2-31

Description of User Interface Screens ..................................... 2-32

Screen Selection Menu Map...............................................................2-32

Machine Feed Back ............................................................................2-33

About the Main Screen ............................................................ 2-34

Machine Controls................................................................................2-35

Lock Group .........................................................................................2-38

About Manual Operation.......................................................... 2-39

Jog Controls........................................................................................2-40

Screw..................................................................................................2-41

Carousel .............................................................................................2-41

Lock ....................................................................................................2-41

Feed....................................................................................................2-42

About the Setup Screen........................................................... 2-43

Enter a Positive or Negative Number .................................................2-43