User Guide User Guide

Page 2 Page 2

Fibroptic Thermometer Fibroptic Thermometer

TheLAND UNO range of highaccuracy thermometers and rugged mountingaccessories

is designed to provide precise, non contact temperature measurement solutions.

Internal controls for emissivity or non-greyness together with selectable time functions

allow the thermometer to be configured to suit a wide range of industrial applications.

A comprehensive range of mountings is common to other LAND products maximising

commonality and simplifying sytem upgrades.

1.3 Unpacking the thermometer

The package containing the thermometer will contain the following items:

lEnvelope containing this User Guide.

lUNO Fibroptic thermometer, optic head (fitted with protection cap) and

lightguide.

lDocumentation binder with dividers.

l2.5mm Hex screwdriver.

l2.5mm flat bladed screwdriver.

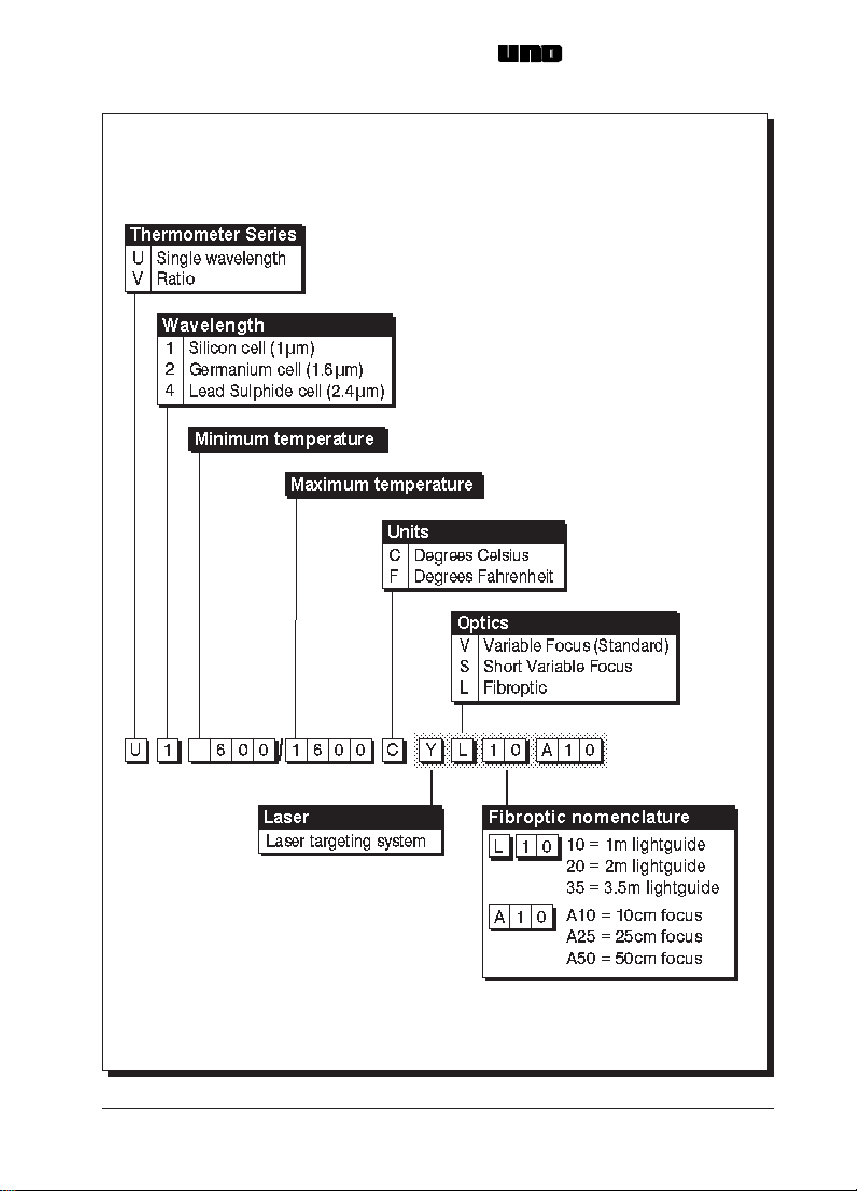

1.4 Nomenclature

The thermometer detail label is on the rear face of the thermometer above the electrical

connector. The thermometer instrument type nomenclature is explained in Fig. 2.

Make a note of your thermometer's instrument type and Serial Number in the space

provided below.

Instrument type:

Serial Number:

The optic head variant (A10, A25 or A50) is determined by the type of spacer fitted.

A10 = Red spacer (15mm long) = 10cm focus distance

A25 = Blue spacer (3mm long) = 25cm focus distance

A50 = No spacer fitted = 50cm focus distance

TheLAND UNO range of highaccuracy thermometers and rugged mountingaccessories

is designed to provide precise, non contact temperature measurement solutions.

Internal controls for emissivity or non-greyness together with selectable time functions

allow the thermometer to be configured to suit a wide range of industrial applications.

A comprehensive range of mountings is common to other LAND products maximising

commonality and simplifying sytem upgrades.

1.3 Unpacking the thermometer

The package containing the thermometer will contain the following items:

lEnvelope containing this User Guide.

lUNO Fibroptic thermometer, optic head (fitted with protection cap) and

lightguide.

lDocumentation binder with dividers.

l2.5mm Hex screwdriver.

l2.5mm flat bladed screwdriver.

1.4 Nomenclature

The thermometer detail label is on the rear face of the thermometer above the electrical

connector. The thermometer instrument type nomenclature is explained in Fig. 2.

Make a note of your thermometer's instrument type and Serial Number in the space

provided below.

Instrument type:

Serial Number:

The optic head variant (A10, A25 or A50) is determined by the type of spacer fitted.

A10 = Red spacer (15mm long) = 10cm focus distance

A25 = Blue spacer (3mm long) = 25cm focus distance

A50 = No spacer fitted = 50cm focus distance