1. The end of the pipe to be flared must be cut square and the outside edge free from burrs.

2. The outside edge of the pipe should be chamfered by 45°

3. Internal bore of the pipe should be de-burred

4. If the pipe is plastic covered or coated in any way only remove the first 3mm maximum of

covering.

N.B. Do not use a file or abrasive materials to do this as the resultant damage will significantly weaken

the flare

5. After flaring remove all debris from inside the pipe.

N.B. To ensure a good flare is made every time ensure dies and punches are clean, dry and free from

oil contamination on assembly.

Instructions for Preparation of Use

Instructions for Preparation of Use

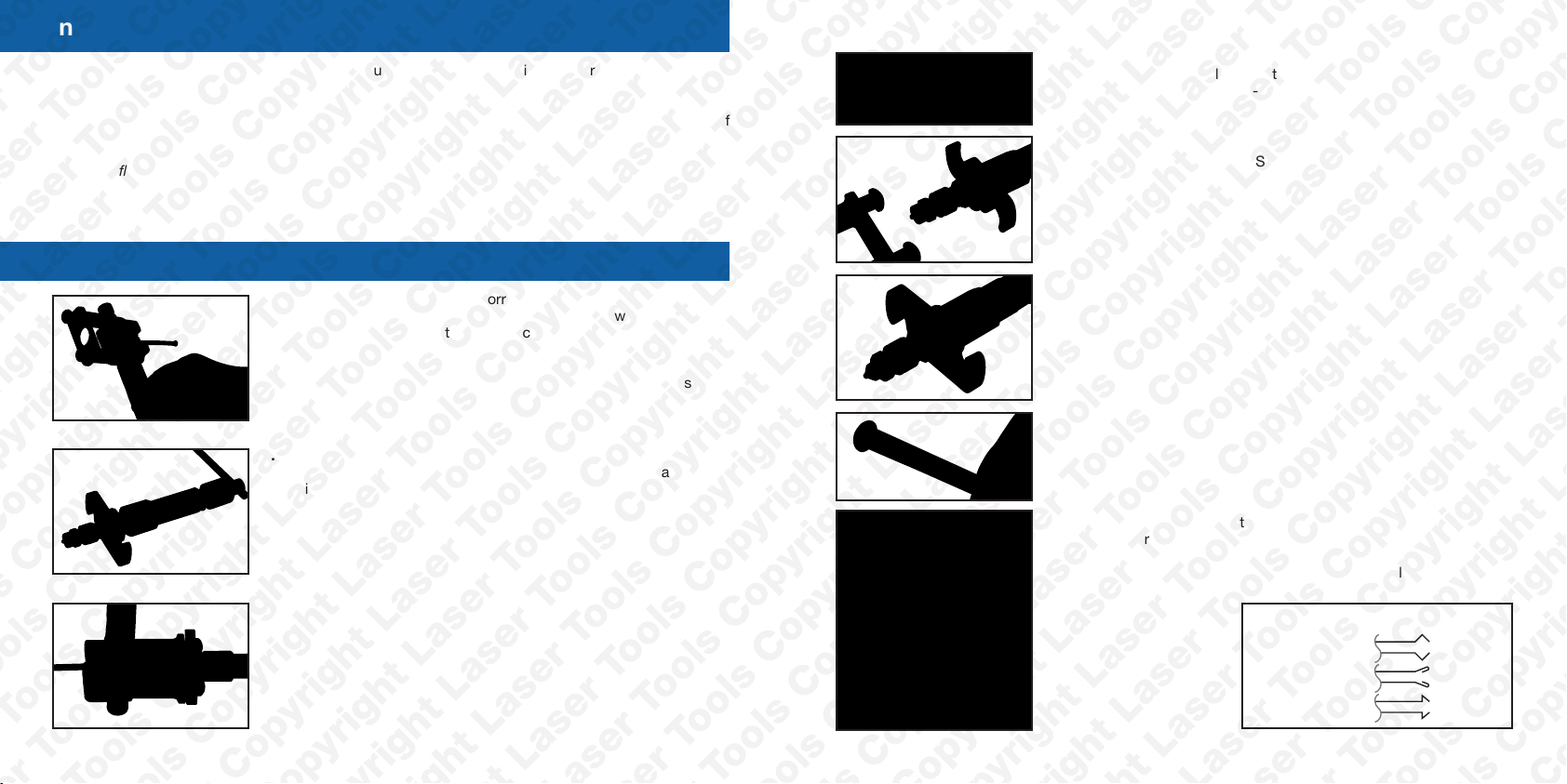

1. Identify and assemble the correct dies for the flare and pipe size

required. Assemble the dies and pipe as shown with the pipe

end flush with top of the dies block,

Note: The dies are marked on their inner faces with SAE at one end

and DIN at the other, ensure the dies are assembled with the

ends matching. Remember the end of the pipe should be square

and free from burs.

2. Select the required punch and fit into quick fit adaptor on the

ram. Fit the “S” shaped “Quick Adaptor” onto the ram and screw

it half way up the rams thread as shown.

3. Insert the punch/ram combination into the yoke and turn the “S

Quick Adaptor” so it locates on to the yoke and screw the ram

body fully in to the “S Quick Adaptor” ensuring the punch end

aligns with and enters the end of the pipe.

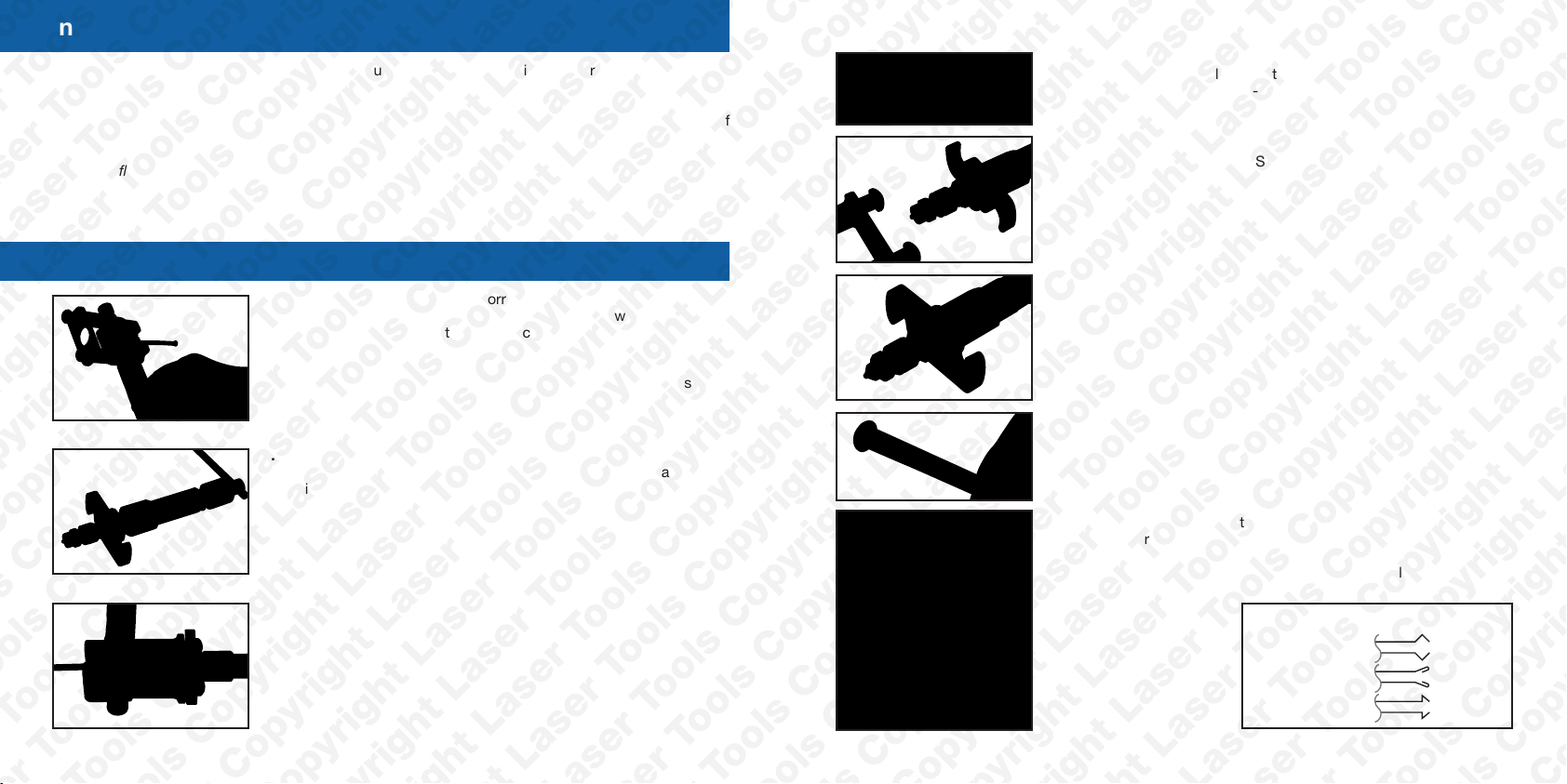

4. Turn the Hydraulic T handle in a clockwise direction until the

rubber seal makes light contact with the seal cover as shown.

Do not overtighten the O-ring.

5. Wind the T bar fully back (anticlockwise) and separate the ram

from the yoke using the “S Quick Adaptor”.

6. If an Operation 2 is required, remove the existing OP1 punch by

pulling back on the Ram end sleeve. Now fit OP2 punch and re-

assemble the tool.

7. Wind the T bar clockwise again to form the reverse cone flare.

8. Where space is limited the 4938 kit is provided with a mechanical

force screw (K) that can be used with an appropriate ratchet

wrench.

(Keep the force screw thread lubricated with oil).

SAE

Single Flare = = OP1

Double Flare = = OP2

DIN =