CALIBRATION PROCEDURE

NI PXIe-5170R

This document contains the verification and adjustment procedures for the NI PXIe-5170R

(NI 5170R). Refer to ni.com/calibration for more information about calibration solutions.

Contents

Required Software.....................................................................................................................1

Related Documentation.............................................................................................................2

Test Equipment..........................................................................................................................2

Test Conditions..........................................................................................................................5

Password................................................................................................................................... 6

Calibration Interval................................................................................................................... 6

As-Found and As-Left Limits................................................................................................... 6

Measurement Uncertainty......................................................................................................... 6

Calibration Overview................................................................................................................6

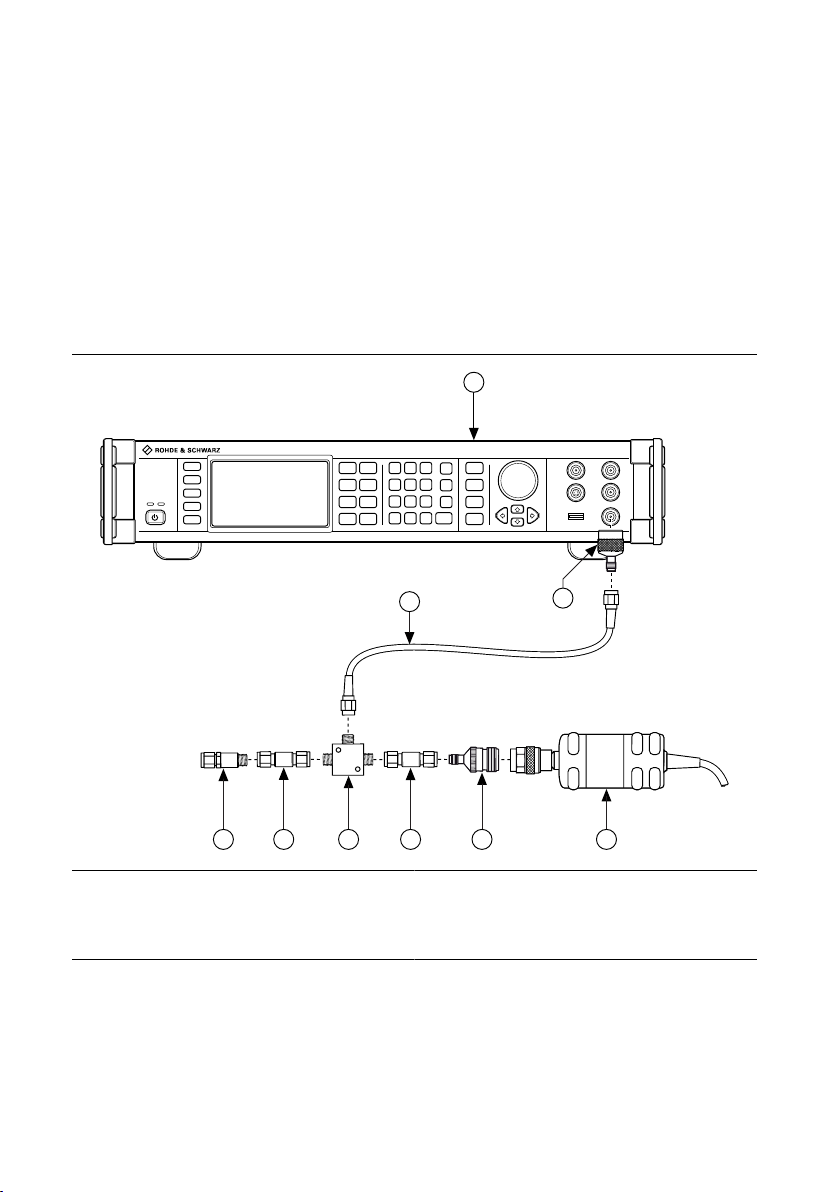

Test System Characterization....................................................................................................7

Zeroing the Power Sensor................................................................................................. 7

Characterizing Power Splitter Amplitude Imbalance....................................................... 7

Verification..............................................................................................................................10

Verifying Timebase Accuracy......................................................................................... 11

Verifying DC Accuracy...................................................................................................12

Verifying AC Amplitude Accuracy.................................................................................14

Verifying Flatness and Bandwidth.................................................................................. 18

Adjustment.............................................................................................................................. 21

Adjusting DC.................................................................................................................. 21

Adjusting Timebase.........................................................................................................22

Reverification..........................................................................................................................23

Updating Verification Date and Time..................................................................................... 23

Worldwide Support and Services............................................................................................ 23

Required Software

Calibrating the NI 5170R requires you to install the following software on the calibration

system:

• LabVIEW Instrument Design Libraries for Reconfigurable Oscilloscopes. The NI 5170R

was first supported in LabVIEW Instrument Design Libraries for Reconfigurable

Oscilloscopes 14.0.

You can download all required software from ni.com/downloads.