Zone

Zone

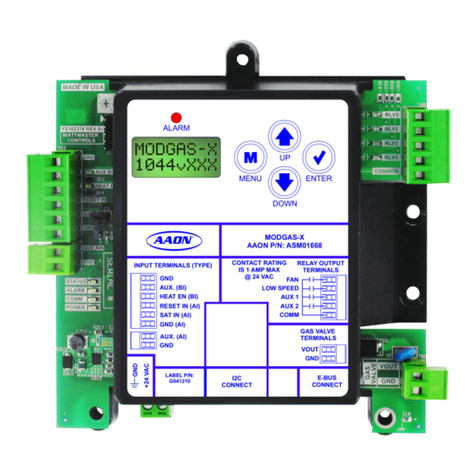

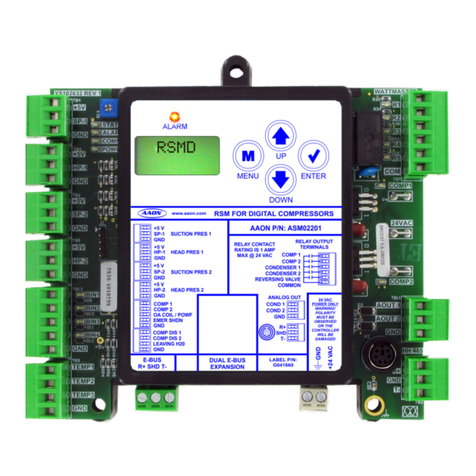

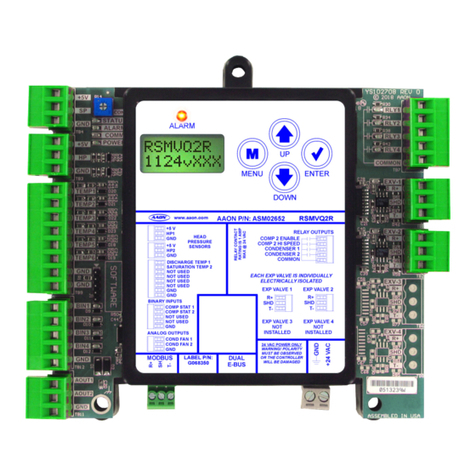

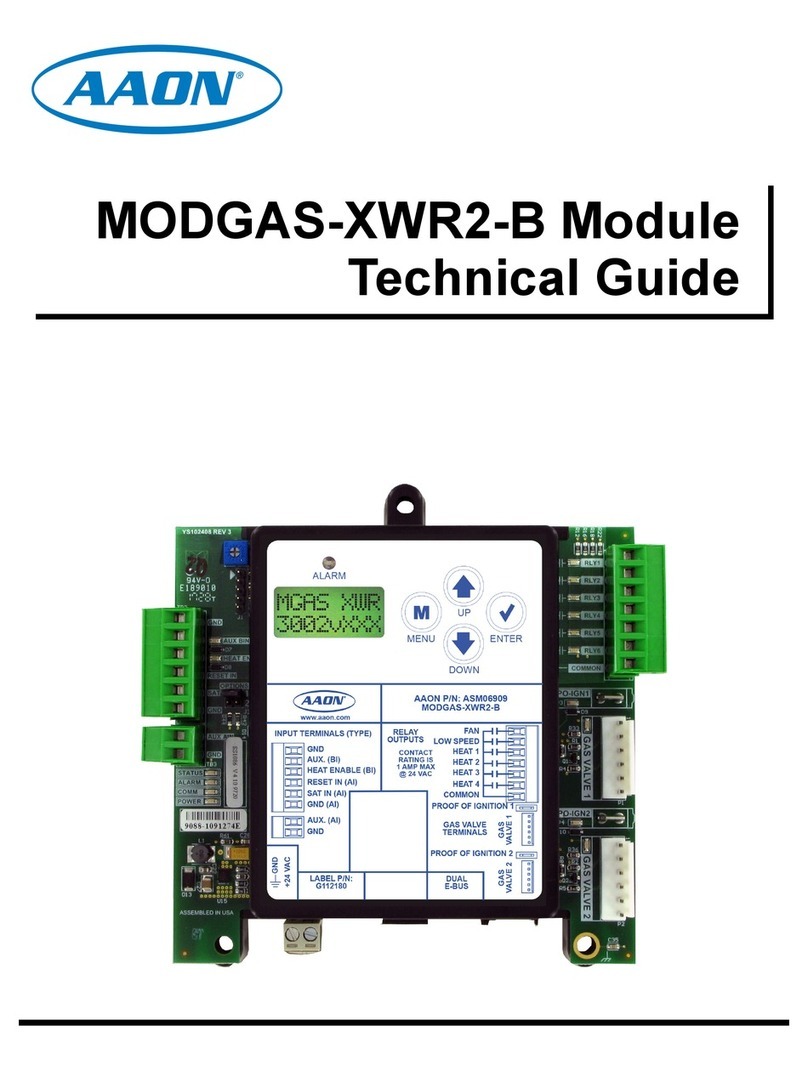

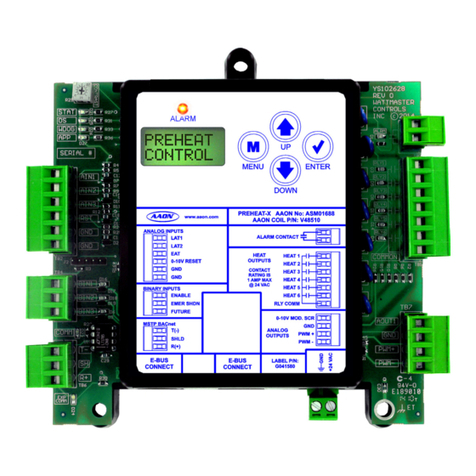

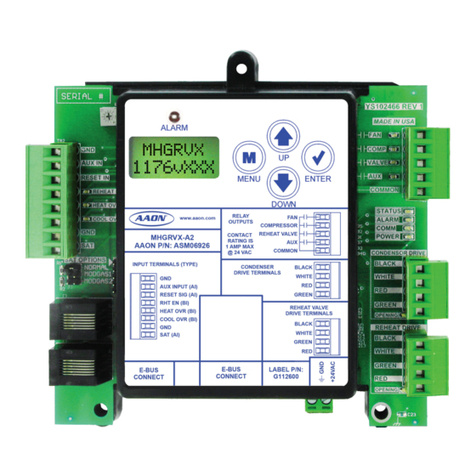

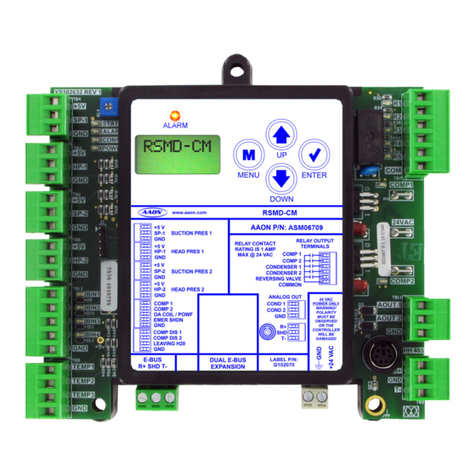

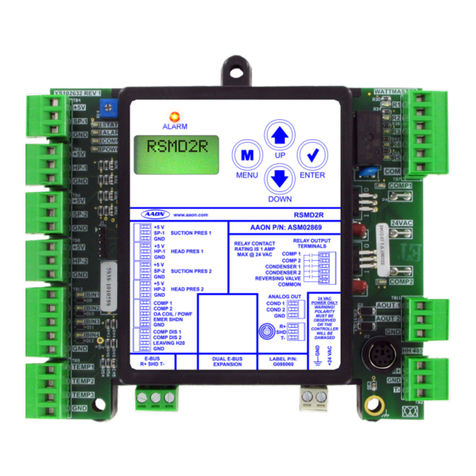

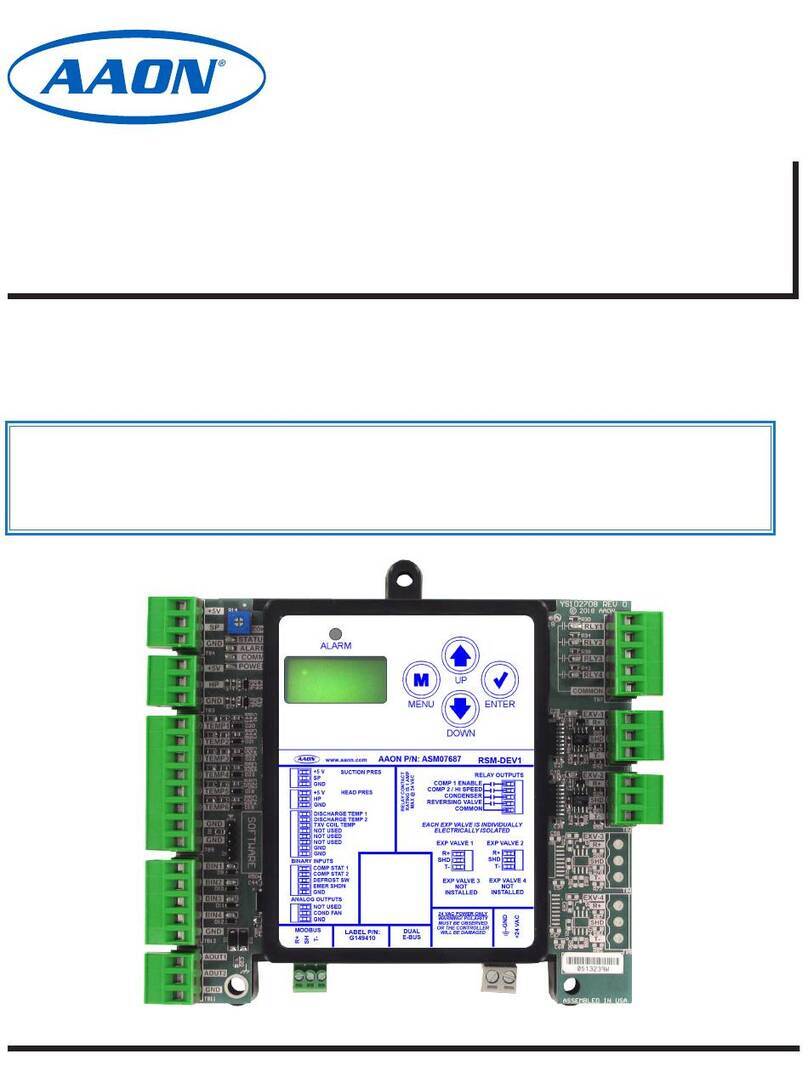

INTERFACE OVERVIEW

Operator Interfaces SD

6

System Manager SD Keys and Buttons

Operator Interfaces

In order to confi gure and program the Orion System controllers,

you must have an Operator’s Interface or a personal computer with

the Prism 2 computer front-end software installed. Three diff erent

Operator Interfaces are available for programming of the Orion

Controls System—the Modular Service Tool SD, the Modular Sys-

tem Manager, the System Manager TS II (all controllers except

VCC-X & VCCX2). These devices allow you to access the status

and setpoints of the controllers on your communications loop. This

manual describes the Modular Service Tool SD. If using the Modular

System Manager or System Manager TS II, please see the VCM-X

/ RNE Operator Interfaces Technical Guide or the System Manager

TS II Technical Guide. If using Prism 2, please see the Prism 2

Technical Guide.

The Modular System Manager SD allows you to view any input or

output status and change any setpoint to fi ne-tune the operations of the

total system. All keypad operations are simple and straightforward,

Display Screens & Data Entry Keys

See the chart below for a list of the keypad descriptions and functions.

Keypad

Description

Key Function

Modular System Manager SD

PREV Use this key to access the

Setup Screens.

ESC Use this key to exit from screens or from data

entry or to return to the Main Screen from any

screen in the system.

ENTER Use this key to enter a new value.

Clear If a data entry mistake is made, press this key

to clear the data entry fi eld and start over.

Minus If a setpoint with a negative value is required,

press this key for the minus sign.

DEC Press this key when entering data that requires

a decimal point.

Use these keys to change values in the

Confi guration Screens as prompted.

Use these keys to step backward or forward

through the screens.

Mode Selection Buttons

The Modular System Manager is provided with “Mode Selection

Buttons.” These buttons give you instant access to the specifi c mode

desired without having to scroll through several menu screens to

get there.

Button

Description

Modular System Manager SD

STATUS Pressing this button takes you directly

to the controller “Status” screens.

SETPOINTS Pressing this button takes you directly

to the controller “Setpoints” screens

and “Confi guration” menu.

SCHEDULES Pressing this button takes you directly

to the controller “Schedules” screens.

OVERRIDES Pressing this button takes you directly

to the controller “Overrides” screen.

See the “Override Button” section on

page 11 for a description of this func-

tion. See Notes 1 & 2 below.

ALARMS Pressing this button takes you directly

to the controller “Alarms” screen. See

the “Alarms Button” section on page

11 for a description of this function.

See Notes 1 & 2 below.

Notes:

(1) This button only functions when the system is confi gured

for “Network Mode” or “Multiple MGRS Mode.” It will

not function in “Stand Alone Mode.”

(2) The “Search for Units” function must be performed on

the System Manager upon initial system setup before this

function will be available. See the “Network Mode & Mul-

tiple Managers Loop Search” on page 10 of this manual for

complete instructions on performing a loop search.

Table 1: Keypad Descriptions

Table 2: Button Descriptions