LDM RV 102 Operating and maintenance manual

The instructions for installation and maintenance of valves RV 102, 103 (further in text only RV10x) are binding

for users to ensure proper function of valves. The user must keep the rules said here while installation,

operation and maintenance. Technical details of individual execution are specified in catalogue data sheets.

TECHNICAL DESCRIPTION AND VALVE FUNCTION

1.1 Description

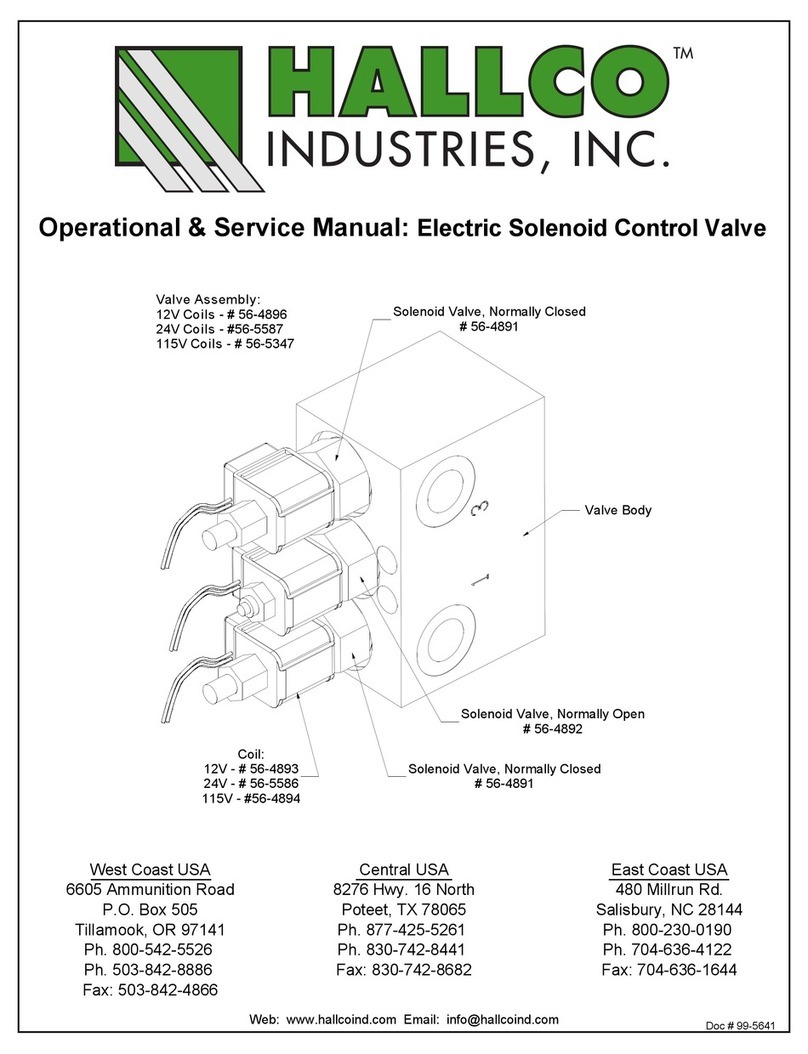

Control valves RV 102 are two-way or three-way valves with threaded connection. Valve body is made of

bronze. Control valves RV 103 are two-way or three-way valves with flanged connection. Valve body is made of

grey cast iron. Flow characteristics, Kvs values and leakage are acc. to international standards.

Valves can be used as : - three-way control valve

- two-way control valve with reversing function

- two-way angular control valve

Valves RV 10x are designed for hand wheel (RV 10x R) or for electric and electrohydraulic actuators as

Siemens (RV 10x EL, HL), Sauter (RV 10x ES, HS), Johnson Controls (RV 10x EC), Honeywell (RV 10x EH),

Belimo (RV 10x EB) and Czech of producers as Ekorex+, ZPANová Paka (RV 10x ER, EN).

1.2 Application

The valves are designed for control circuits PN 16. The valves are accurately designed to regulate pressure and

flow of liquids, gases and steams without abrasive particles as water (except of drinking water ) low-pressure

steam (only RV102) and air. Sort of operating medium has to be compatible with the material body. Acidity,

resp. alkalinity of medium has to be in range from pH 4.5 to pH 9.5. For proper function the producer

recommends to install a filtr into the pipeline in front of the valve .

The valve cannot work in cavitation conditions. RV 103 valves are not suitable for steam and steam

condensate.

1.3 Function

Control Valves serie RV 10x can have equal percentage plug or linear plug. Used actuators allow 3-point

controlling. They can be equipped with the signalization of end positions and transmitters of position.

1.4 Differential pressure

Value Dp is maximum differential pressure when on-off function is always guaranteed. Recommended

max

constant pressure drop should not be higher than 0.6 MPa for valves RV 102. For valves RV 103 pressure drop

should not be higher than 0,4 MPa.

1.5 Valve body specifications

1.

PM - 009/12/01/GB

LDM, spol. s r.o.

Czech Republic

®

RV 102

RV 103

INSTRUCTION FOR INSTALLATION AND MAINTENANCE

CONTROL VALVE

DN 15 - 50 PN 16

Series

Type

Nominal diameter DN

Nominal pressure PN

Body material

Building length

Operating temperature

Connection

Flow characteristic

Kvs values

Leakage

Packing set

RV 102 RV 103

Three-way control valve

Two-way control valve with reversing function

DN 15 - 50

PN 16

Acc. to DIN 3202 - M4

Socket with female thread

Acc. to ÈSN EN ISO 228-1

V - ported

Linear, equal percentage

Class III. acc. to ÈSN EN 1349 (<0.1% Kvs) in way A-AB

O - ring EPDM

Acc. to ÈSN EN 1092-1

Flange with raise face, type B1

Acc. to ÈSN EN 558-1 - F1

3

from 0.6 to 40 m /h

Bronze 42 3135 (CuSn5Pb5Zn5) G EN-JL 1040rey cast iron

Brass 42 3234 (CuZn40Pb2)

Plug material

from 0°C to 150°C

Type of plug

Rangeability 50:1

PM - 009/12/01/GB _ RV 102, 103 1/6

2. DIRECTIONS FOR INSTALLATION

2.

The valves are delivered from the company assembled, adjusted and tested. Before valve´s installation into

pipiline you must check the data on the name-plate with data mentioned in accompanying documentation.

Then check if the valve or the actuator are not damaged and dirty. Pay attention especially to inner spaces and

packing surfaces of valve.

2.2 Dimensions and weights of valves RV 10x

1 Preparation before installation

RV 102

D -with actuators Siemens and

L,B

Belimo

D -with actuators Sauter

S

D -with actuators Johnson Controls

C

D -with actuators Honeywell,Ekorex+

H,E

and ZPA Nová Paka

H - with actuators Siemens, J.Controls,

Honeywell, Belimo, Ekorex+and

ZPA Nová Paka

H -with actuators Sauter

S

RV 102 RV103

DN L1V2

V1HHSDL,B DSDCDH,E m

mm mm mm

mm mm mm mm mm mm mm kg

15

20

25

32

40

50

85

95

105

120

130

150

27

32

41

50

58

70

43

48

53

66

70

80

10 10

16 14

8 M6

M 8x1

0.55

0.65

0.80

1.40

2.00

2.95

1/4´´UNF

C

G 1/2

G 3/4

G 1

G 1 1/4

G 1 1/2

G 2

L1L2L3

9

11

12

14

16

18

mm

12

14

16

18

20

22

S

mm

25

25

25

35

35

42

DN D1D2D3nxd afL1V1V2HHSDL,B DSDCDH,E m

mm mm mm mm mm mm mm mm mm mm mm mm mm mm mm kg

15

20

25

32

40

50

95

105

115

140

150

165

65

75

85

100

110

125

45

58

68

78

88

102

4 x 14

4 x 18

16

18

20

2

3

130

150

160

180

200

230

65

75

80

90

100

115

25

25

25

35

35

42

10 10

16 14

8 M6

M 8x1

3.2

4.3

5.5

7.7

8.5

11.9

1/4´´NF

RV 103 MIX. 2-cest.

m

kg

4.0

5.4

6.8

9.7

10.9

15.6

PM - 009/12/01/GB _ RV 102, 103 2/6

2.3 Installation of valve into pipeline

Valve must be installed into pipeline so that flow of medium is according to arrows on the body. The

actuator can be installed in any position except the position below the valve body. Keep the rules in

instalation and maintenance instructions of actuator too. Protection of actuator against the radiant heat can

be necessary in case of high temperature application. As a basic provision can be made pipeline insulation,

actuator turning aside from vertical position, etc..

For proper function of control valve, below-mentioned instructions must be obeyed :

- no excessive forces can be transfered from pipeline to valve.

- the pipeline must be cleaned from dirt before valve installation.

- the valve can not be installed just behind the bend. Pipeline should be straight min. 6xDN in front of the

valve.

- it is recommended to keep clean space around the valve for easy manipulation and service.

- installation itself must be done precisely. Pipeline flanges must be coaxial with valve flanges.

- it is necessary to use connectioned pipe union for valves with threaded connection during its installation so

that the dismantling of valve from the pipeline will be possible and can be carried out.

2.3.1 Electric actuator or electrohydraulic actuator connection

These work may be carried out by trained personnel only. It is necessary to keep all safety rules relating to

electric machines. Further it is necessary to follow instructions for installation, operation and maintenance of

electric actuators issued by the producer. Position transmitter and signalisation switches, if part of delivery, are

positioned under the actuator cover.

Before valve commissioning, the data, given in the actuator ID plate (especially supply voltage and voltage of

control signal), should be checked/compared with given specification and verify, that the actuator can be

connected to superordinate regulator.

Switching off by torque or power switch is adjusted in upper position for the valves that are equipped only with

the seat in straight way. In position when the straight way is open, the switching the actuator off is adjusted by

limit switch or torque switch with the use of the stop.

In case the actuator is dismantled from the valve body for any reason such as the valve installation into pipeline

etc., it is necessary to check the setting again after the assembly possibly to carry out the complete setting of

actuator again. Producer does not take over the guarantee if the damage was caused by improper setting or

adjusting of the actuator. In case of need, it is possible to ask for such service from service organization of the

producer.

The length of the actuator´s cables shall be selected so that the actuator can be removed from the valve without

disconnection from the terminal board.

2.3.2 Checking after installation

Piping system should be pressured after valve installation and the checked if there is not leak. Check the

packing set tightness as well. Then check the proper function of actuator by doing a few strokes.

2.4 Operating and Maintenance

2.4.1 Packing set

The packing set does not need a lot of servicing in the case that the valve has PTFE or O-ring EPDM packing

set, and also in this case gland bolt may not be tightened nor loosen. If leakage is high, the packing set must be

changed.

2.4.2 Exchange of packing set

If there is need to exchange the packing set because of high leakage, first the actuator must be dismantled and

then the packing screw must be screwed out. The pipeline may not be under pressure during changing of

packing set. After this, there is need to check the state of spindle surface and clean the inside of the packing

box. The surface of spindle must be smooth and not damaged. If necessary, the spindle must be exchanged.

Packing set is filled, by the producer, with a special lubricant acc. to the type of used packing. Such lubricant

ensures the proper function of the packing rings within their service life. The spindle may not be greased

during the operation!

After exchange of packing set, the gland bolt must be tightened to the bottom of packing box.After installation of

actuator, there is necessary to make test as in 2.3.2.

2.4.3 Exchange of plug

When the valve is used for medium with high dirt-content is probability that packing surface of plug will be wear

out and internal leakage of valve will be too high (seat - plug leakage). In this case the professional service must

be called.

Regarding the fact the valve is delivered with its actuator as a complet, the basic adjusting is carried out.

PM - 009/12/01/GB _ RV 102, 103 3/6

2.4.4 Electric actuators

Electric actuators have to be operated according to instructions given in „ Actuator manual ”. In case of

malfunction of actuator, see the instructions or ask for professional repair man.

2.5 Elimination of defects and malfunctions

If a defect is detected on the valve (leakage, leakage of packing or bonnet sealing, etc.), it is necessary to

ensure its repair immediately otherwise a permanent damage may occur to sealing surfaces and other parts

exposed to effects of leaking medium. Prior to any repair work on the valve, make sure that piping system

is free of pressure!

2.5.1 High leakage of valve

High leakage can be caused:

1 - when the valve is used under the higher differential pressure than Dpmax.

2 - by insufficient thrust of actuator. There is need to test the function of actuator again.

3 - by damaged seating faces of plug and seat. In this case the professional service must be called.

2.5.2 High leakage of packing set

In the case of high leakage of the packing set, points 2.4.1. and 2.4.2. must be done or professional service

must be called.

2.6 Spare parts

Spare parts are not part of valve delivery. They must be ordered separately. For the spare parts order, following

data must be written: type of a valve, nominal diameter DN, Serial valve´s number, name of a spare part.

2.7 Guarantee conditions

The producer does not guarantee the operation and safety of the product under conditions different from data

given in the catalogue data sheet. Any using of the valve under different conditions shall be consulted with the

producer. Defects of the valve caused by impurities in process medium shall be considered as out of guarantee

terms. The producer does not take over the guarantee if any change was made by the user without prior written

consent from the producer.

2.8 Waste disposal

Packaging and the valves (after their scrapping) shall be disposed off in the common way, e.g. by handing over

to a specialized company for a disposal (body and metal parts - metal scrap, packaging + other non-metallic

parts - communal waste).

PM - 009/12/01/GB _ RV 102, 103 4/6

1. Valve Control valve

2. Type of valve Valve from bronze - threaded

Valve from grey cast iron - flanged

Electric actuator

Electrohydraulic actuator

Hand wheel

Two-way threaded

Two-way threaded angular

Three-way threaded mixing (distributing)

Two-way flanged

Two-way flanged angular

Three-way flanged mixing (distributing)

5. Body material Grey cast iron

Bronze

6. Flow characteristic Linear

Equal percentage

7. Kvs values Column number acc. to table Kvs values

8. Nominal pressure PN PN 16

9. Operating temperat. °C

10. Nominal diameter DN

XX XXX XXX XX XX XX / XXX - XX

3. Actuator

4. Connection

RV

102

103

EXX

HXX

RXX

1

2

3

4

5

6

3

5

1

2

X

16

140

150

XX

RV 103

RV 102

Valve complete specification No. for ordering RV 10x

Ordering example: Three-way valve DN 25, PN 16, with electric actuator SQX 32.00, body material bronzthreaded

3

connection G 1, linear characteristic, Kvs = 10 m /h, is marked as: RV 102 ELA 3511 16/140-25

Maximum permissible working pressure [MPa]

Temperature [°C]

Material PN

120 150 200 250 300

16

16

Grey cast iron EN-JL 1040

Bronze 42 3135

1.60

1.60

1.44

1.09

1.28

0.73

1.12

-- 0.96

--

PM - 009/12/01/GB _ RV 102, 103 5/6

ADDRESS OF FACTORY

REGIONAL OFFICES

LDM SUBSIDIARIES ABROAD

LDM, spol. s r.o.

Litomyšlská 1378

560 02 Èeská Tøebová

Czech Republic

tel.: +420 465 502 511

fax: +420 465 533 101

E-mail: [email protected]

http://www.ldmvalves.com

LDM Armaturen GmbH

Wupperweg 21

D-51789 Lindlar

Deutschland

tel: +49 2266 440333

fax: +49 2266 440372

mobile: +49 1772960469

Guarantee and after guarantee service provided.

®

LDM, spol. s r.o. reserves the right to modify or improve the designs or specifications of such products at any time without notice

LDM, spol. s r.o.

Office in Ústí nad Labem

Ladova 2548/38

400 11 Ústí nad Labem - Severní Terasa

Czech Republic

tel.: +420 602708257

E-mail: [email protected]

LDM, spol. s r.o.

Office in Prague

Podolská 50

147 01 Praha 4

Czech Republic

tel.: +420 241087360

fax: +420 241087192

E-mail: [email protected]

LDM, Bratislava s.r.o.

Mierová 151

821 05 Bratislava

Slovakia

tel: +421 243415027-8

fax: +421 243415029

http://www.ldm.sk

LDM, Polska Sp. z o.o.

ul. Modelarska 12

40-142 Katowice

Polska

tel: +48 327305633

fax: +48 327305233

mobile: +48 601354999

E-mail: [email protected]

LDM Bulgaria Ltd.

z.k.Mladost 1

bl.42, floor 12, app.57

1784 Sofia

Bulgaria

tel: +359 2 9746311

fax: +359 2 8771344

mobile: +359 888925766

www.ldmvalves.com

SERVICE ORGANIZATION

LDM servis, spol. s r.o.

Litomyšlská 1378

560 02 Èeská Tøebová

Czech Republic

tel: +420 465502411-13

fax: +420 465531010

PM - 009/12/01/GB _ RV 102, 103 6/6

1015

OOO "LDM Promarmatura"

Jubilejniy prospekt, dom.6a, of. 601

141407 Khimki

Moscow Region

Russia

tel.: +7 495 7772238

fax: +7 495 7772238

mobile: +7 9032254333

e-mail: inforus@ldmvalves.com

TOO “LDM”

Shakirova 33/1, kab. 103

100012 Karaganda

Kazachstan

tel.: +7 7212566936

fax: +7 7212566936

mobile: +7 7017383679

e-mail: [email protected]

This manual suits for next models

1

Table of contents

Other LDM Control Unit manuals

Popular Control Unit manuals by other brands

Contec

Contec ADI16-4(FIT)GY manual

MC Crypt

MC Crypt 59 11 57 instruction manual

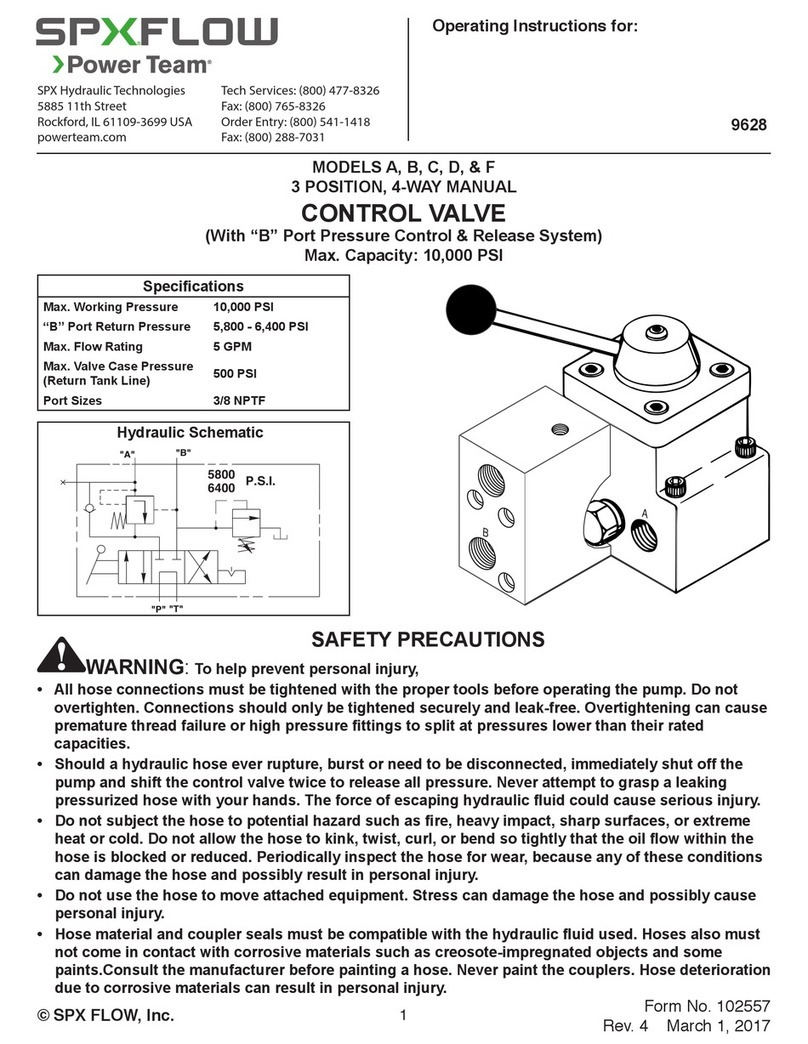

SPX FLOW

SPX FLOW APV DELTA DKR2 instruction manual

Goldline

Goldline AQL-BASE-RF Installation and operation guide

SPX FLOW

SPX FLOW Power Team A operating instructions

American Flow Control

American Flow Control 2500 Series product manual