Soldering instruction

Provided you have no special experience in soldering electronic

components please read first this soldering instruction before starting

the job. Soldering has to be trained!

1. Never use additional fluxes for soldering electronic circuits which

contain acids (e.g. zinc chloride or ammonium chloride). Those can

destroy components and printed circuits when not washed off

completely.

2. As soldering material only lead free soldering tin with a rosin core

for fluxing should be used.

3. Use a small soldering iron with max 30 Watt heating power. The

solder tip shall be free from scale to assure an excellent heat

transfer to the area to be soldered.

4. The soldering shall be performed on a speedy way because a long

heat transfer can destroy the components. To much or to long

heating can take off the copper pads and copper tracks from the

board.

5. For a good soldering a well tinned solder-tip has to be brought in

contact to the copper-pad and the component wire at the same

time. Simultaneous a little solder-tin shall be applied for heating up.

As soon as the solder-tin starts melting the tin wire has to be taken

away. Just wait until the tin has well wetted the pad and the wire

and take the soldering iron away from the soldering area.

6. Make sure not to move the just soldered component for about 5

seconds after removing the soldering iron. This should create a

silver shining faultless soldering joint.

7. For a faultless soldering joint and well done soldering is a clean

non-oxidized soldering-tip absolutely required. It is not possible to

perform a sufficient soldering joint with a dirty soldering tip.

Therefore please clean the soldering tip from excessive solder-tin

and dirt by using a wet sponge or a silicone cleaning pad after each

soldering process.

8. After completion of the soldering all connection wires have to be

cutted off directly above the soldering joint by using a side cutter.

9. By soldering semiconductors (transistors, diodes), LED`s and IC`s

is it very important never to exceed the soldering time of 5 seconds

to prevent the destruction of the component. It is absolutely

required to attend to the correct polarity of the component before

starting the soldering process.

10. After the board assembly carefully control the pc-board about

correct insertion of the components and the correct polarity. Please

check if no connections or copper tracks are accidentally short

circuited by soldering tin. This can not only result to malfunction of

the module but also result to a destruction of expensive

components.

11. Please take into account that improper soldering joints, wrong

connections, faulty operation or wrong board assembly is not a

matter within our sphere of influence.

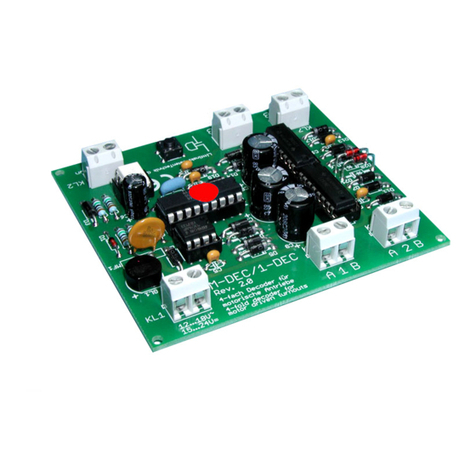

General installation information

The contact-wires of resistors and diodes to be assembled in a lying

position shall be bended in accordance to the raster distance into a right

angular position and assembled into the specified bores (in accordance

to the board assembly plan or the assembly markings). To prevent that

the components will not fall out by turn-over the pc-board please bend

the connection wires about 45° apart and solder them carefully to the

copper pads on the rear side of the board. Finally the excessive wires

shall be cutted off with a small side cutter.

The resistors in the supplied kits are metal-foil resistors. Those have a

tolerance of 1% and are marked with a brown “tolerance-ring”. The

tolerance ring can be identified by the larger margin distance

respectively the larger distance to the other four marking rings.

Normally there are five color rings on the metal-foil resistors. To read

the color code you have to locate the resistor that way that the brown

tolerance ring will be on the right side. The color rings will be red now

from left to right!

Please take care to assemble diodes with the correct polarity (position

of the cathode marking). Take care about a very short soldering time!

The same will apply to the transistors and the integrated circuits (IC`s).

The flat side of the transistors has to correspond with the marking on

the pc-board.

The transistor legs should never be assembled in a crossed position.

Further those components should have a distance of about 5mm to the

board. Attend to the short soldering time to prevent the damage of the

component by excessive heat.

Capacitors shall be assembled into the respective marked bores, the

wires to be bent a little apart and careful soldered to the copper pad. By

the assembly of electrolytic capacitors (electrolytic cap) it has to be

attended to the correct polarity (+,-)! Wrong-way soldered electrolytic

capacitors can explode during the application! Therefore is it very

important to check the correct polarity two-or even better three-times.

In addition it has to be attended to the correct capacitor values, e.g. n10

= 100pF (not 10nF!).

A careful and clean assembly will drastically reduce the possibility that

anything will not be in correct function. Check every step and every

soldering joint two times before carrying on! Attend closely to the

assembly list! Perform the described step not different and do not skip

any step! Mark each step as done at the foreseen column after

assembly and careful check.

Take your time. Private work is no piece-work because the time for

careful assembly work is much less than an extensive fault diagnosis.

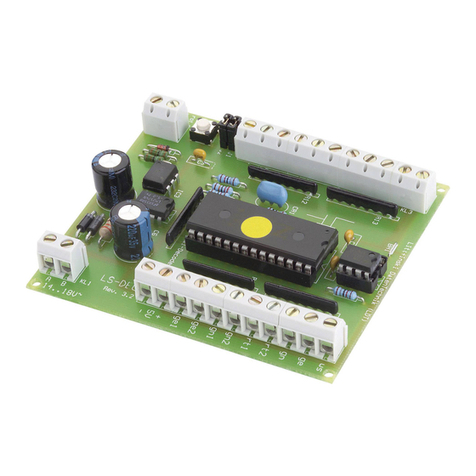

Final assembly

Sockets and integrated circuits (IC´s) of the kits will be supplied on a

piece of foam to assure safe transport.

This foam shall never be used below or between components as this

foam is electrical conductive.

In case the kit will be taken into operation the conductive foam can

produce a short circuitry and destroy the complete kit. Anyhow the

function of the module will not be as expected.

Warranty

As we have no influence to the proper and correct assembly we have to

limit our warranty to the complete supply and the faultless quality of the

components.

We guarantee the function of the components in accordance to the

identified values within a non-assembled condition of the parts and the

compliance of the technical data of the circuit by attending to the

respective soldering instruction and the specified start of operation of

the module including connection and operation.

Further demands are not accepted.

We are not taking over any warranty nor any liability for any harm or

sequential damage connected to this product.

We reserve our right for a repair, rework, supply of replacement or

refund of the purchase price.

The following criteria will result to a non-repair respectively to a lost of

right to claim under guarantee:

•if acid-containing soldering tin or fluxes with corrosive content and

others have been used

•if the kit has been improper soldered or assembled

•by alterations or repair-trials on the device

•by own circuit amendments

•by construction of non-intended improper displacement of

components, free wiring of components etc.

•application of other non-original kit-components

•by damaging of copper tracks or soldering copper pads on the

board

•by wrong assembly and the sub sequential damages

•overloading the module

•by damages caused by intervention of foreign persons

•by damages caused by disregarding the operation manual

respectively the connection plan

•by connecting a wrong voltage respectively a wrong current

•by wrong polarity connection of the module

•by wrong operation or damages caused by negligent usage or

abuse

•by defects caused by bridged or wrong fuses.

All such cases will result to a return of the kit to your expenses.

Subject to technical changes and errors. 05/2013 by LDT