Littfinski DatenTechnik (LDT)

4-fold decoder for motor

driven turnouts

from the Digital-Professional-Series !

M-DEC-DC-F Part-No.: 410412

>> finished module <<

Suitable for the DCC-Format:

e.g. Lenz-, Arnold-, Roco-, LGB-Digital, Intellibox,

TWIN-CENTER, Digitrax, Zimo, Märklin-Digital=,

EasyControl, KeyCom-DC, ECoS, DiCoStation and

others

(switching of turnouts via Lokmaus 2® and R3® is possible)

For the digital control of :

⇒Up to four turnout motor drives.

(e.g. drives from Fulgurex, Pilz or Hoffmann/Conrad)

⇒Motor current per output up to 1A.

This product is not a toy! Not suitable for children under 14 years of age!

The kit contains small parts, which should be kept away from children under 3!

Improper use will imply danger of injuring due to sharp edges and tips! Please

store this instruction carefully.

blue point

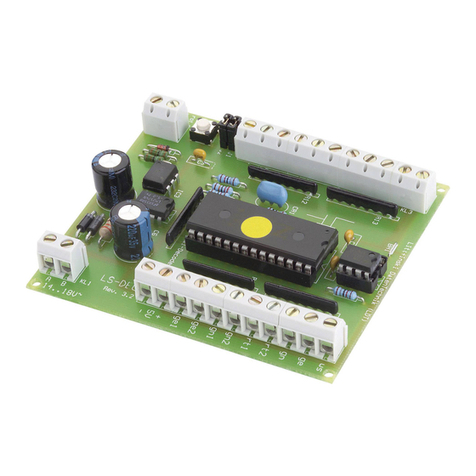

Introduction/Safety instruction:

You have purchased the 4-fold decoder M-DEC-DC for motor

driven turnouts for your model railway as a kit or as finished

module supplied within the assortment of Littfinski

DatenTechnik (LDT).

We are wishing you having a good time using this product.

The M-DEC-DC (receiver device is marked blue) is suitable for

the DCC Data format, used for instance at the systems of

Arnold-Digital, Intellibox, Lenz-Digital Plus, Roco-Digital,

TWIN-CENTER, Digitrax, LGB-Digital, Zimo, Märklin-

Digital=, EasyControl, KeyCom-DC, ECoS and DiCoStation.

The decoder M-DEC-DC can not only switch turnouts via the

turnout addresses but also responds to loc-addresses.

Therefore is it possible to shift turnouts with the keysF1 to F4 of

the Lokmaus 2® or R3®.

The decoder M-DEC-DC is multi digital and can be installed to

the Intellibox and on the TWIN-CENTER without any problems.

The finished module comes with a 24 month warranty.

•Please read the following instructions carefully. Warranty will

expire due to damages caused by disregarding the operating

instructions. LDT will also be not liable for any consequential

damages caused by improper use or installation.

Connecting the decoder to your digital

model railway layout:

•Attention: Before starting the installation switch off the

drive voltage by pushing the stop button or disconnect

the main supply to all transformers.

The decoder receives the digital information via the clamp

KL2. Connect the clamp directly to the command station or to a

booster assuring the supply of digital information free from any

interference.

The DCC-Digital-Systems uses different color codes

respectively indications for the two digital cables. Those

markings are indicated next to the clamp KL2.These markings

have not necessarily to be maintained correct as the decoder

converts the signal automatically to be correct.

The decoder receives the power supply via the two pole clamp

KL1. Voltage in the range of 14 to 18V~ is acceptable (alternate

current output of a model railway transformer).

If you do not want to supply power to the decoder M-DEC from

an external transformer you can connect the clamp KL1 to

KL2 with two wires. In this case the decoder will get the power

supply complete from the digital system.

Programming the decoder address:

To program the decoder-address a motor driven turnout has to

be connected to the output 1 (clamp KL9) of the decoder.

•Switch on the power supply of your model railway.

•Adjust the speed of all connected speed controller to zero.

•Press the programming key S1.

•The turnout drive connected to output 1 will now move a

little every 1,5 seconds. This indicates that the decoder is in

the programming mode.

•Is the motor not moving is it possible that the motor drive

contains directional diodes. In this case switch off the power

supply and turn around the two connection wires on output

1. After switching power on the turnout drive should move at

a 1,5 second interval.

•Switch now one turnout of a group of four assigned to the

decoder via the keyboard of the control unit or via a remote

control unit.

For programming the decoder address you can also release a

turnout switch signal via a personal computer.

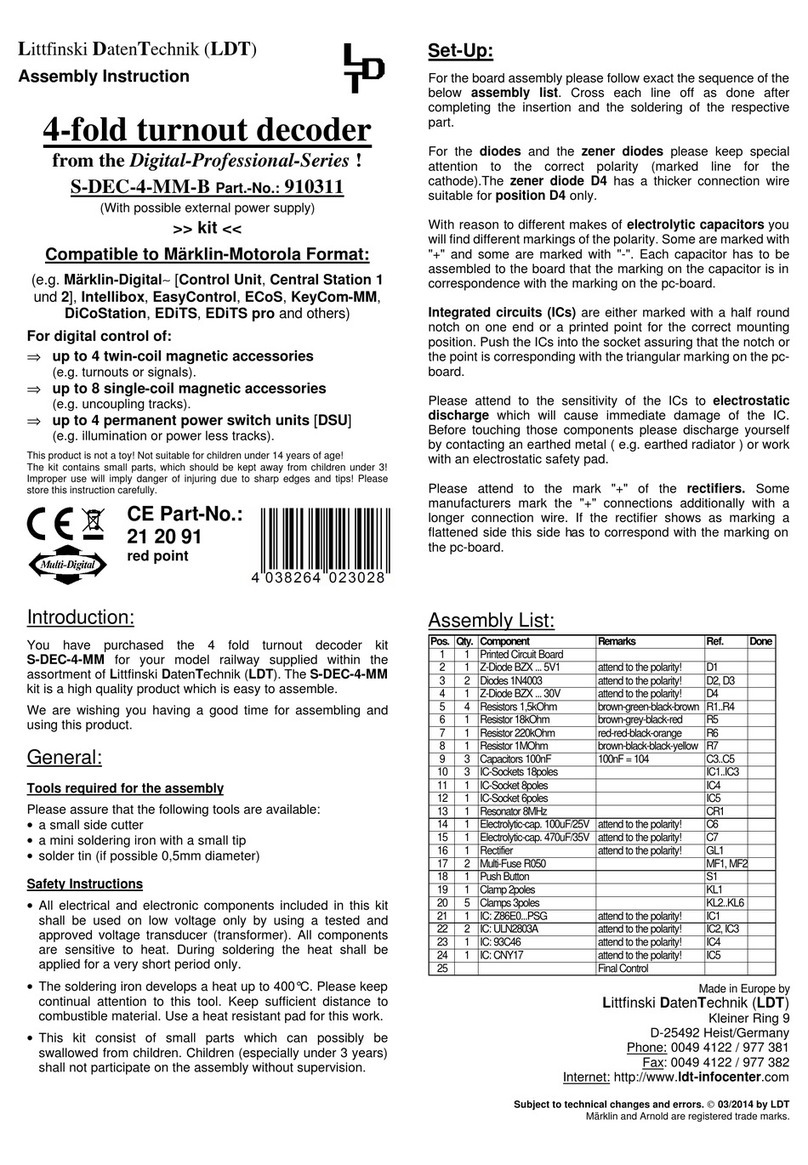

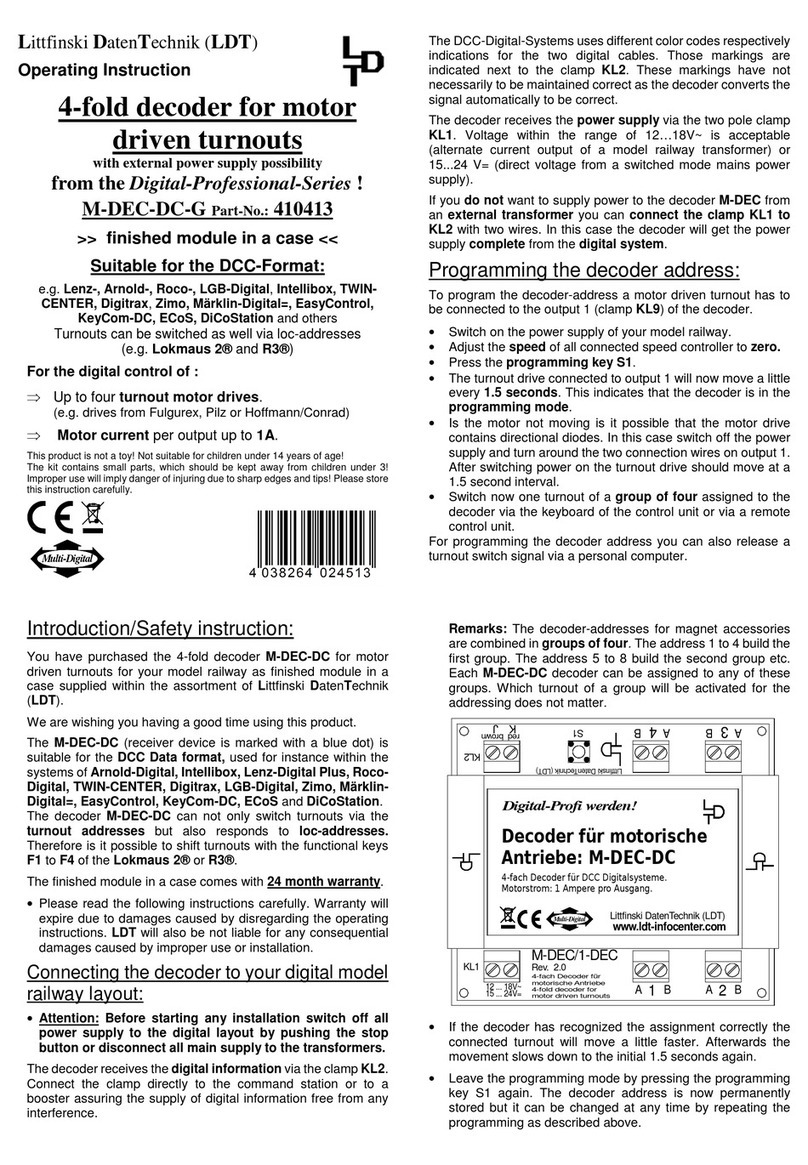

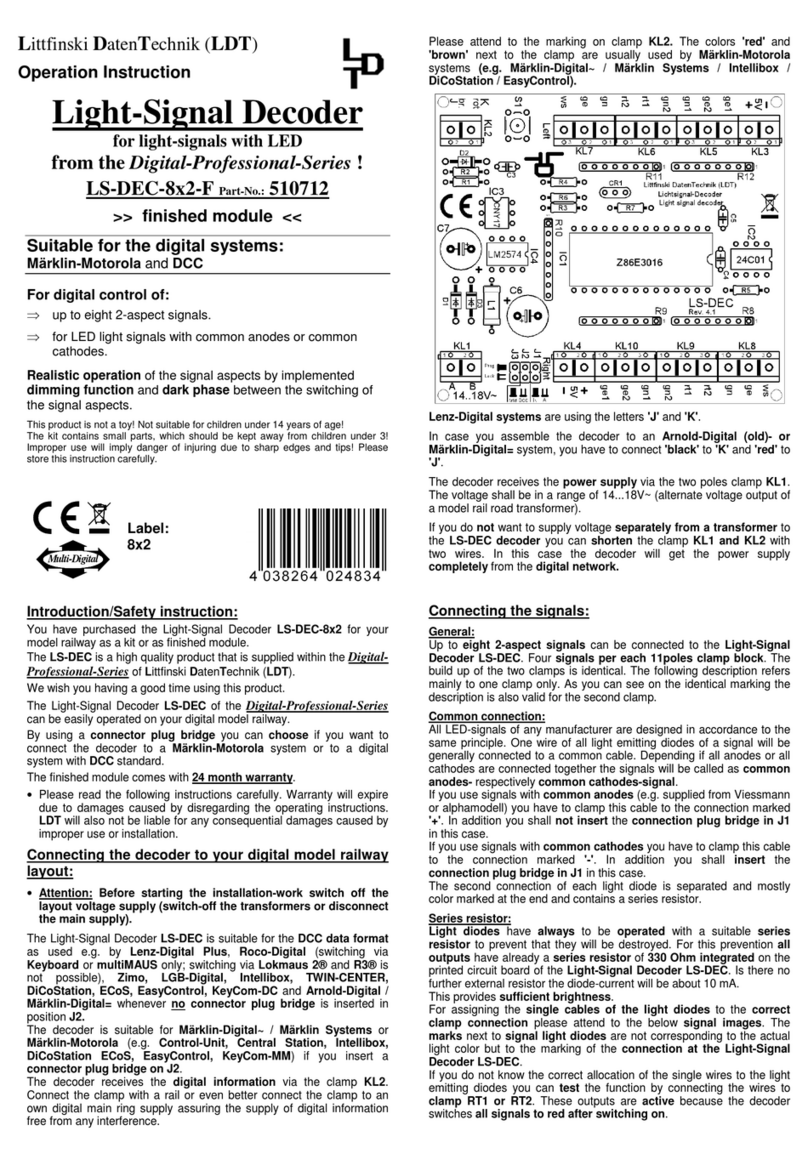

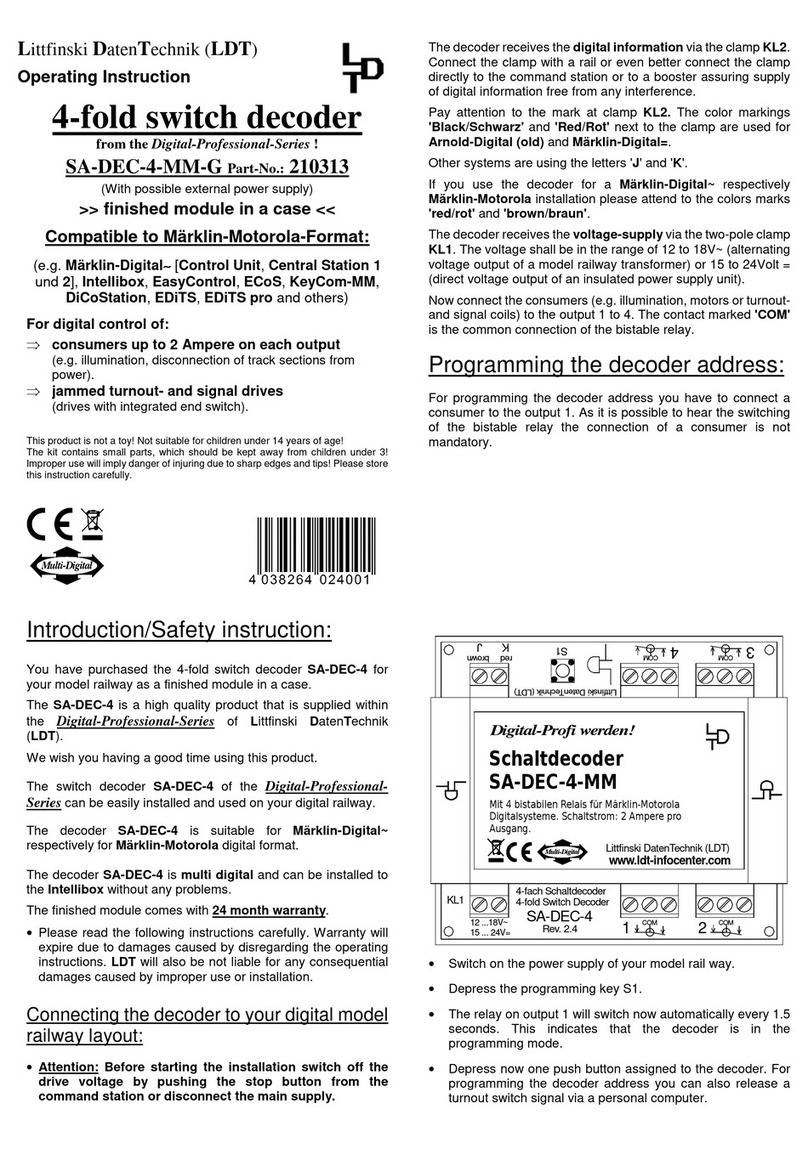

D16

D9

R7

D21

S1

C3

C5

C4

93C06IC4

D4

D5

R2

R1

D10

D11

Z86E0408

IC1

R6

B80C1500

GL1

D1

L293B

IC3

L293B

IC2

C7

D6

KL1

KL2

R5

MF1

C6

4N25

IC5

D20

R4

R3

D7

D8

D15

D14

D19

D18

D13

D12

D17

KL8KL9

KL7KL6

C9

D3

D2

C10

C11

C8

CR1

Ver. 1.3

Littfinski DatenTechnik (LDT)

14..18V~

B

A

B

A

B

A

B

A

M-DEC

BR2

BR1

3

4

2

1

rot braun

KJ

fuer

motorische Antriebe

4fach Decoder

Rot

Schwarz

Remarks: The decoder-addresses for magnet accessories

are combined in groups of four. The address 1 to 4 build

the first group. The address 5 to 8 build the second group

etc. Each M-DEC-DC decoder can be assigned to any of

these groups. Which turnout of a group will be activated for

the addressing does not matter.

•If the decoder has recognized the assignment correctly the

connected turnout will move a little faster. Afterwards the

movement slows down to the initial 1,5 seconds again.

•Leave the programming mode by pressing the programming

key S1 again. The decoder address is now permanently

stored but it can be changed at any time by repeating the

programming as described above.

•If you press the first key of the programmed group of keys or

you send a switch signal for this turnout from a PC the

addressed turnout drive should move into the called

direction until end-stop.