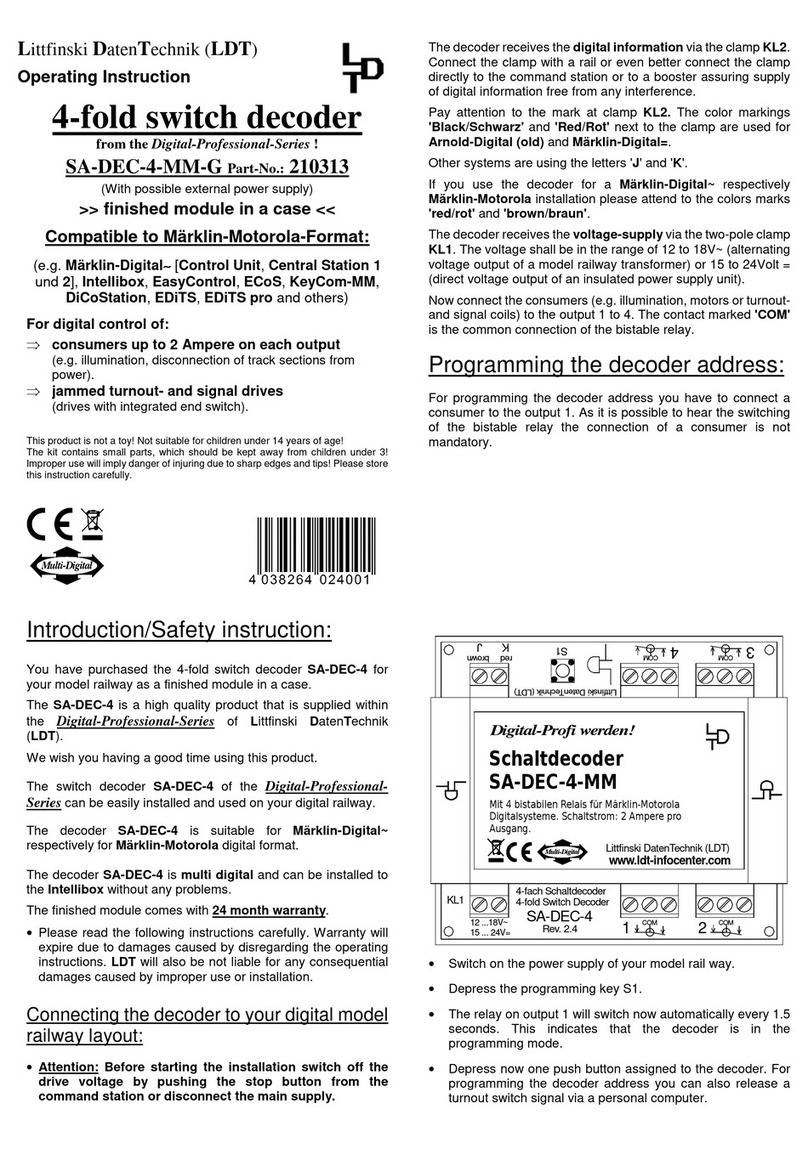

LDT M-DEC-DC-F User manual

L

ittfinski

D

aten

T

echnik (

LDT

)

Operating Instruction

Multi-Digital

4-fold decoder for motor

driven turnouts

with external power supply possibility

from the Digital-Professional-Series !

M-DEC-DC-F

Part-No.:

410412

>> finished module <<

Suitable for the DCC-Format:

e.g. Lenz-, Arnold-, Roco-, LGB-Digital, Intellibox, TWIN-

CENTER, Digitrax, Zimo, Märklin-Digital=, EasyControl,

KeyCom-DC, ECoS, DiCoStation and others

Turnouts can be switched as well via loc-addresses (e.g.

Lokmaus 2® and R3®)

For the digital control of :

⇒Up to four turnout motor drives.

(e.g. drives from Fulgurex, Pilz or Hoffmann/Conrad)

⇒Motor current per output up to 1A.

This product is not a toy! Not suitable for children under 14 years of age!

The kit contains small parts, which should be kept away from children under 3!

Improper use will imply danger of injuring due to sharp edges and tips! Please store

this instruction carefully.

CE Part-No.:

24 00 05

blue point

Introduction/Safety instruction:

You have purchased the 4-fold decoder M-DEC-DC for motor

driven turnouts for your model railway as a kit or as finished

module supplied within the assortment of Littfinski DatenTechnik

(LDT).

We are wishing you having a good time using this product.

The M-DEC-DC (receiver device is marked with a blue dot) is

suitable for the DCC Data format, used for instance within the

systems of Arnold-Digital, Intellibox, Lenz-Digital Plus, Roco-

Digital, TWIN-CENTER, Digitrax, LGB-Digital, Zimo, Märklin-

Digital=, EasyControl, KeyCom-DC, ECoS and DiCoStation.

The decoder M-DEC-DC can not only switch turnouts via the

turnout addresses but also responds to loc-addresses.

Therefore is it possible to shift turnouts with the functional keys

F1 to F4 of the Lokmaus

2® or R3®.

The finished module comes with 24 month warranty.

•Please read the following instructions carefully. Warranty will

expire due to damages caused by disregarding the operating

instructions. LDT will also be not liable for any consequential

damages caused by improper use or installation.

Connecting the decoder to your digital model

railway layout:

•Attention: Before starting any installation switch off all

power supply to the digital layout by pushing the stop

button or disconnect all main supply to the transformers.

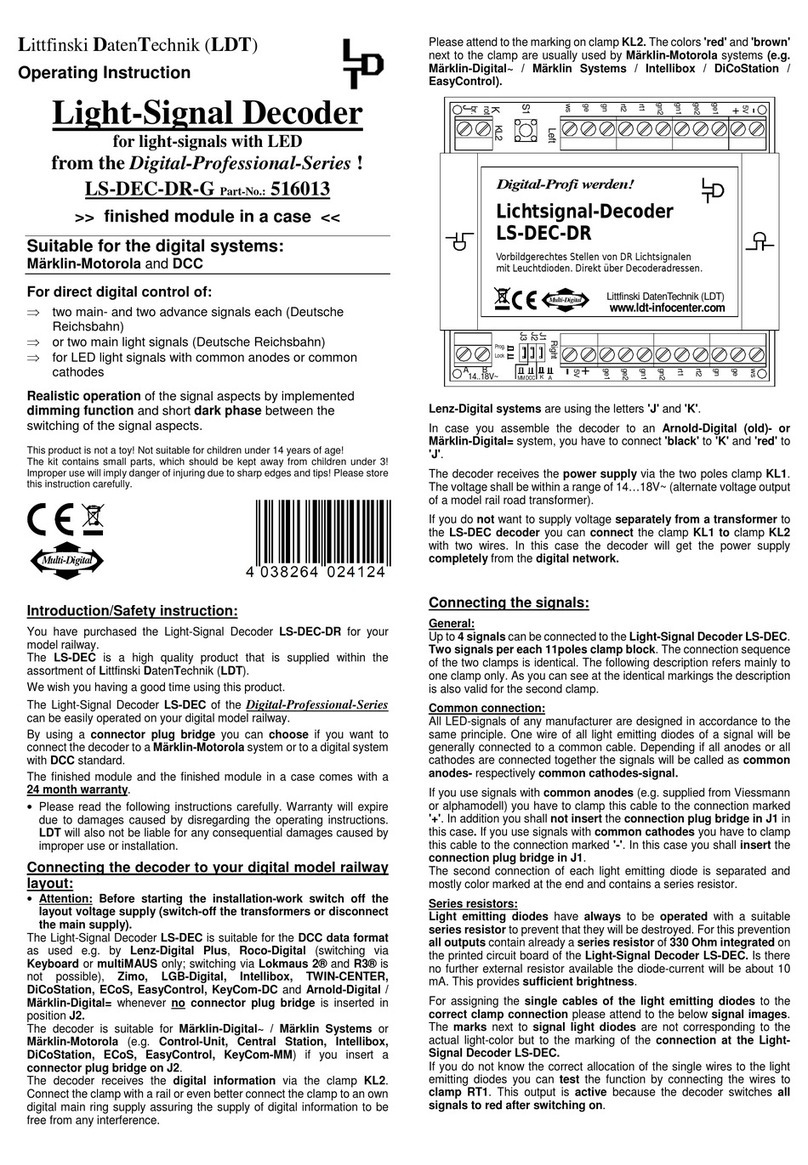

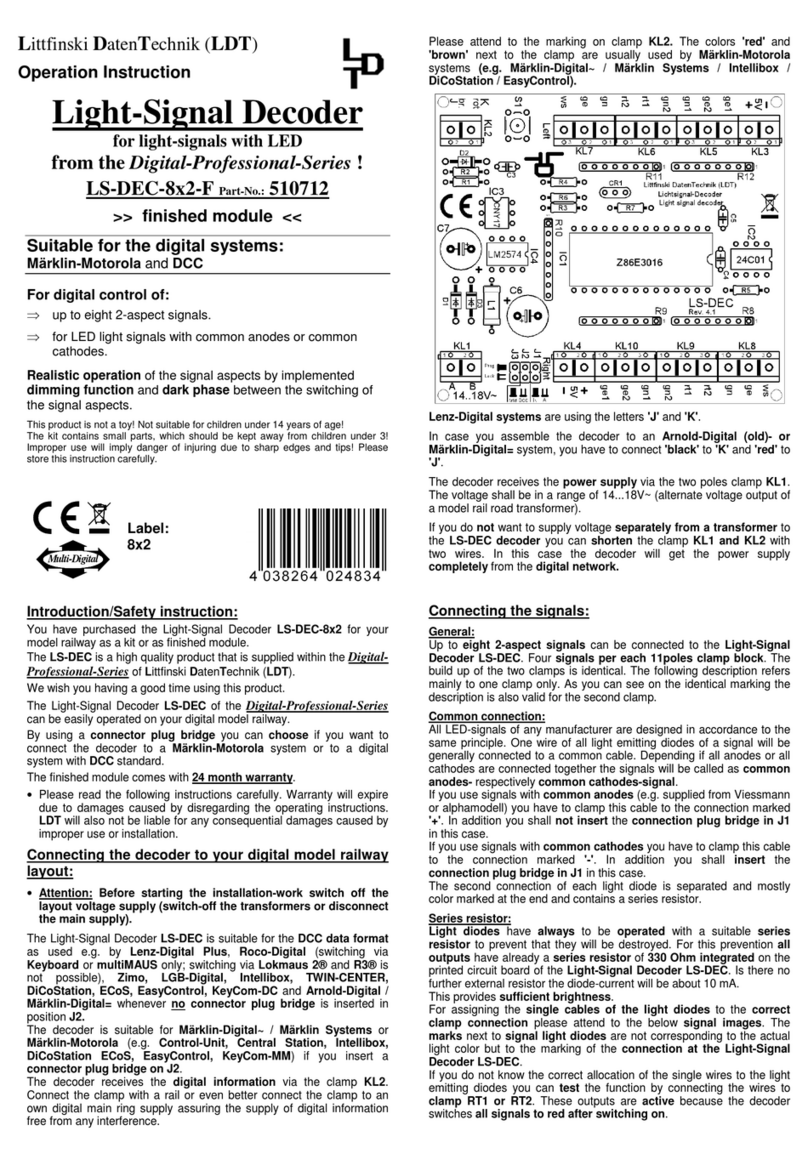

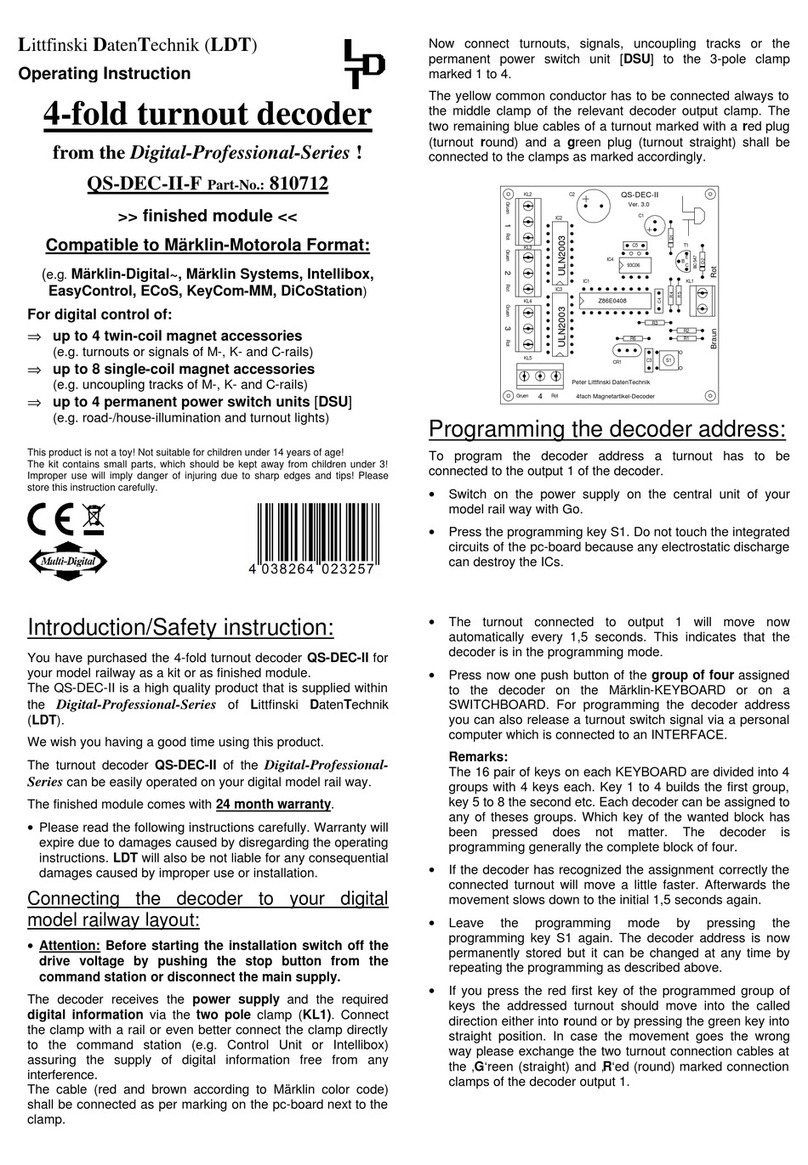

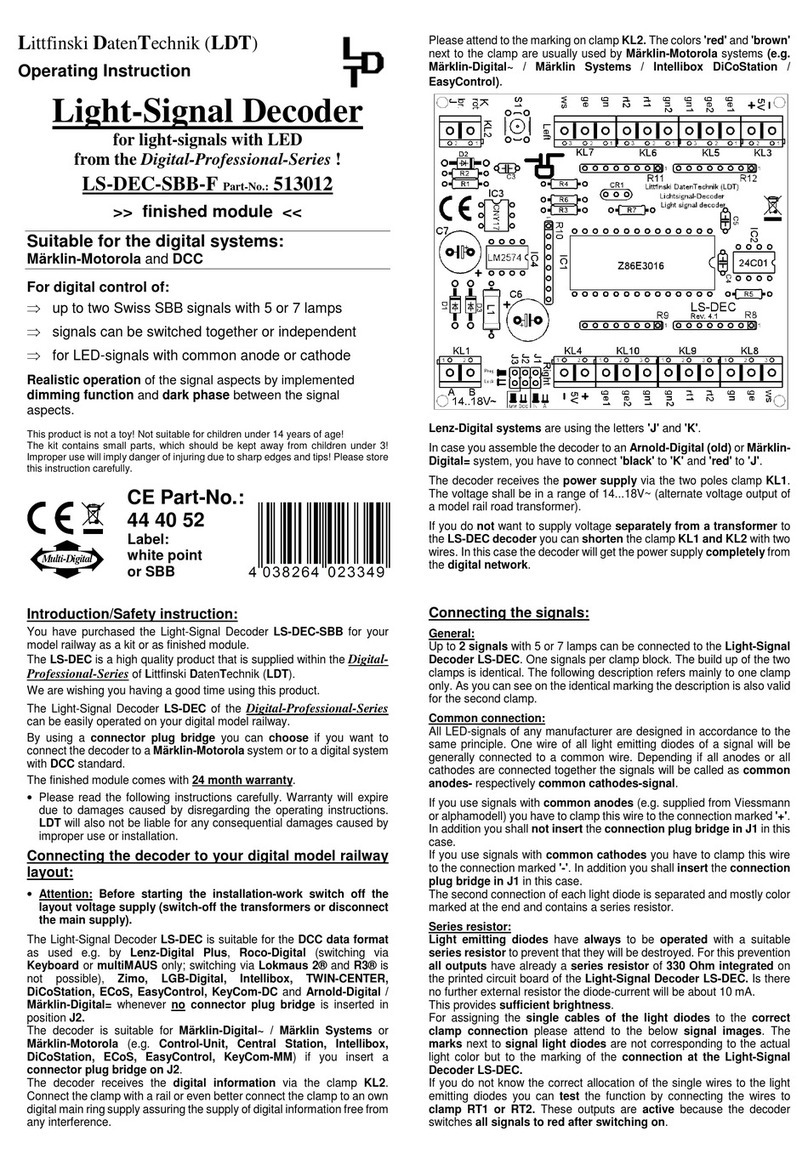

The decoder receives the digital information via the clamp KL2.

Connect the clamp directly to the command station or to a

booster assuring the supply of digital information free from any

interference.

The DCC-Digital-Systems uses different colorcodes respectively

indications for the two digital cables. Those markings are

indicated next to the clamp KL2.These markings have not

necessarily to be maintained correct as the decoder converts the

signal automatically to be correct.

The decoder receives the power supply via the two pole clamp

KL1. Voltage within the range of 12…18V~ is acceptable

(alternate current output of a model railway transformer) or

15...24 V= (direct voltage from a switched mode mains power

supply).

If you do not want to supply power to the decoder M-DEC from

an external transformer you can connect the clamp KL1 to

KL2 with two wires. In this case the decoder will get the power

supply complete from the digital system.

Programming the decoder address:

To program the decoder-address a motor driven turnout has to

be connected to the output 1 (clamp KL9) of the decoder.

•Switch on the power supply of your model railway.

•Adjust the speed of all connected speed controller to zero.

•Press the programming key S1.

•The turnout drive connected to output 1 will now move a little

every 1.5 seconds. This indicates that the decoder is in the

programming mode.

•Is the motor not moving is it possible that the motor drive

contains directional diodes. In this case switch off the power

supply and turn around the two connection wires on output 1.

After switching power on the turnout drive should move at a

1.5 second interval.

•Switch now one turnout of a group of four assigned to the

decoder via the keyboard of the control unit or via a remote

control unit.

For programming the decoder address you can also release a

turnout switch signal via a personal computer.

Remarks: The decoder-addresses for magnet accessories

are combined in groups of four. The address 1 to 4 build the

first group. The address 5 to 8 build the second group etc.

Each M-DEC-DC decoder can be assigned to any of these

groups. Which turnout of a group will be activated for the

addressing does not matter.

•If the decoder has recognized the assignment correctly the

connected turnout will move a little faster. Afterwards the

movement slows down to the initial 1.5 seconds again.

•Leave the programming mode by pressing the programming

key S1 again. The decoder address is now permanently

stored but it can be changed at any time by repeating the

programming as described above.

•If you press the first key of the programmed group of keys or

you send a switch signal for this turnout from a PC the

addressed turnout drive should move into the called direction

until end-stop.

Switching turnouts via loc-addresses

(e.g. Lokmaus 2® or R3®):

The decoder M-DEC-DC makes it possible to switch motor driven

turnouts via loc-addresses. For example switching with the

functional keys F1 to F4 of the Lokmaus

2® or R3®.

The function key F1 will shift the drive at the output 1 and the

key F2 will shift the turnout at the output 2 etc.

Each stroke on a function key will shift the respective turnout

from round to straight or vice versa.

Also for programming the loc-addresses a turnout motor-drive

has to be connected to the output 1 of the decoder.

•Switch the power supply of your model rail way on.

•Adjust the speed of all connected speed controller

respectively Lokmauses to zero (center position of the

adjusting dial).

•Press the programming key S1.

•The motor drive connected to output 1 shall move now

automatically every 1.5 seconds. This indicates that the

decoder is in the programming mode.

•Adjust now on one of the Lokmauses the required address

and turn the speed adjusting dial off from the center

position. If the decoder has recognized the assignment

correctly the connected turnout drive will move now a little

faster. The decoder M-DEC-DC will accept loc-addresses

between 1 and 99.

•Adjust the speed now to zero again. The turnout will move

now a little slower.

•Press the programming key S1 again for leaving the

programming mode.

•If you press functional key F1 you can shift the turnout of

the output 1 with each stroke. If there are turnouts

connected on output 2 to 4 of the decoder M-DEC-DC you

can shift the respective registered turnouts with the

programmed loc-addresses with each stroke of the function

keys F2 to F4.

Please attend to the following:

•All 4 decoder outputs can supply a motor current of 1

Ampere. As the moving time of the drives is only some

seconds the tracking time of the decoder output is adjusted

to 10 seconds. This indicates that the respective output will

be switched voltage free 10 seconds after the end of the

switch command. This assures that a defect end-switch will

not destroy a drive with continuous current.

•The motors of turnout drives can create considerable

electromagnetic interference. Normally the decoder

M-DEC will not be influenced by this interference. But in case

the decoder will be influenced please check the turnout drive

installation cables. Those cables should not wrap or cross

the decoder closely. Install the cables that way that they go

straight away from the clamps of the decoder. If limited space

requires a bad installation layout and the function of the

decoder will be disturbed please push about 5 ferrous pearls

onto each motor cable.

These ferrous pearls are available at electronic shops or at

LDT with the order code `FP`.

Another possibility is to solder an interference capacitor

(between 1nF and 10nF) across each motor. Fulgurex drives

need this capacitor in any case.

Accessory

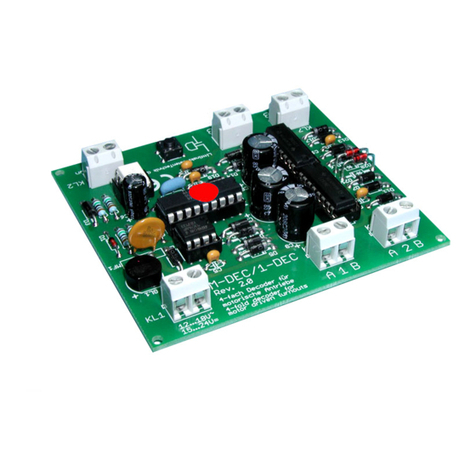

For the assembly of the M-DEC below your layout base plate is

our assembly set MON-Set recommended. For the ready

assembled kits and the finished modules from version 2.0 we

offer a suitable case under the order code LDT-01.

Sample Connections:

Spannungsversorgung

12 ... 18V~

15 ... 24V=

3

4

1

2

Fulgurex

Pilz/Tillig

M-DEC

Digitalinformationen

(von Steuereinheit oder Booster)

Hoffmann

Conrad

The above draft provides an example how to connect the

different drives directly to the M-DEC-DC without any additional

circuitry.

Further application examples can be found in the Internet on our

Web-Site (www.ldt-infocenter.com) at the section

downloads/sample connections.

Trouble shooting:

What to do if something is not working as described above?

If you have purchased the decoder as a kit please check carefully

all parts and soldered joints.

Here some possible functional errors and possible solutions:

1. During programming of the decoder addresses the motor

moves within 1.5 seconds, but does not confirm the

programming with faster movement by pressing any key.

•Interfered digital information at KL2 respectively

considerable lost of voltage at the tracks or at the

installation! Connect the decoder directly with cables to the

digital control unit or to the booster instead to the tracks.

•Eventually the clamps have been tightened to strong and

therefore the clamps got loose at the soldering to the pc

board. Check the soldering connection of the clamps at

the lower side of the pc-board and re-solder them if required.

•For kits: Is IC4 and IC5 correct inserted into the socket?

Has resistor R6 actually 220kOhm or has this resistor been

mixed-up with the 18kOhm resistor R5?

2. The turnout connected to output 1 will move always at a faster

sequence after activating the programming key S1.

•Start programming the decoder for motor driven turnouts

M-DEC-DC immediately after switching-on the digital

central unit before any loc is traveling on the track.

•Perform a RESET of the digital central unit. All stored data

will be preserved but the address-repeating-memory will

be deleted. For Intellibox and TWIN-CENTER please

switch-on the unit and press the keys GO and STOP

simultaneous until the report “reset” can be red at the

display.

3. The drive moves not until the end switch but stops after a

short movement. The decoder does not show any reaction after

some commands.

•This can happen especially by Fulgurex-drives without

interference capacitor. Solving: solder an interference

capacitor (1nF) directly to the motor connection clamps.

Made in Europe by

Littfinski DatenTechnik (LDT)

Bühler electronic GmbH

Ulmenstraße 43

15370 Fredersdorf / Germany

Phone: +49 (0) 33439 / 867-0

Internet: www.ldt-infocenter.com

Subject to technical changes and errors. 05/2019 by LDT

Arnold, Märklin, Lenz, Digitrax, Roco and Zimo are registered trade marks.

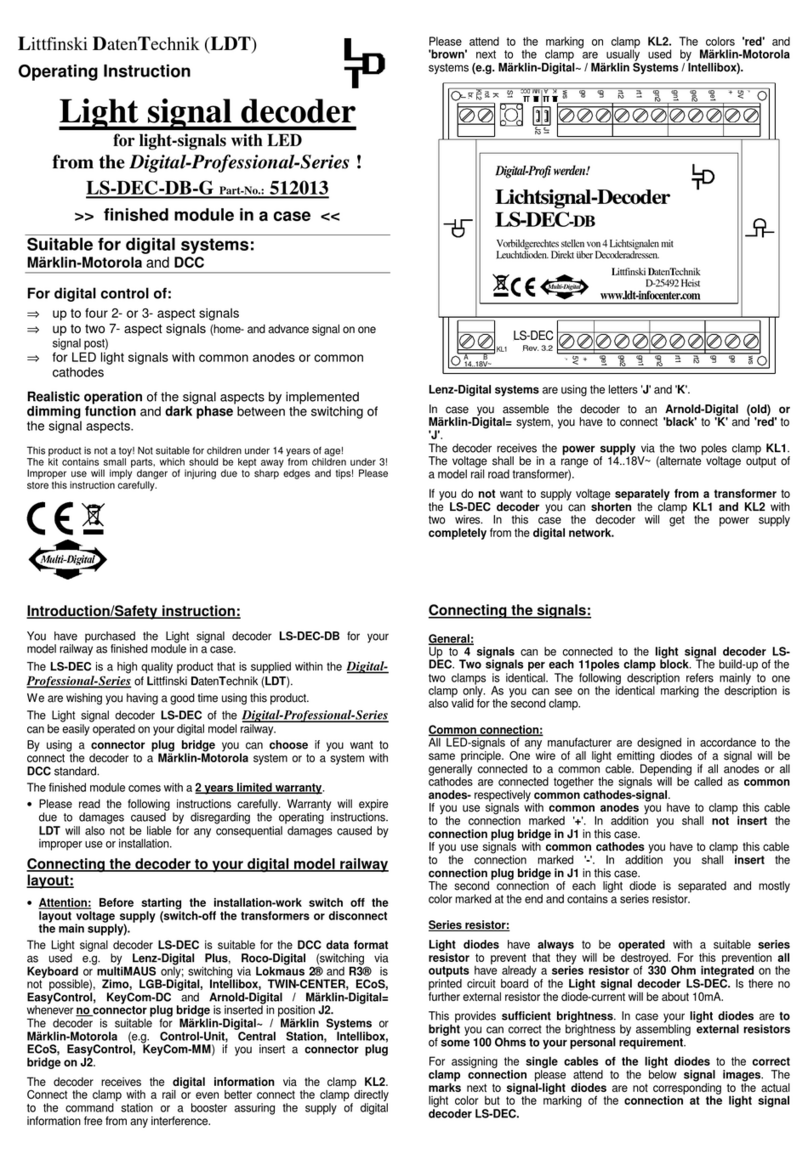

This manual suits for next models

1

Other LDT Media Converter manuals

LDT

LDT SA-DEC-4-MM-G User manual

LDT

LDT LS-DEC-USA User manual

LDT

LDT S-DEC-4-MM-B User manual

LDT

LDT S-DEC-4-DC-G User manual

LDT

LDT M-DEC-MM-F User manual

LDT

LDT M-DEC-DC-G User manual

LDT

LDT LS-DEC-DR-F User manual

LDT

LDT Digital Professional Series User manual

LDT

LDT LS-DEC-CSD-F User manual

LDT

LDT LS-DEC-DB-F Technical manual

LDT

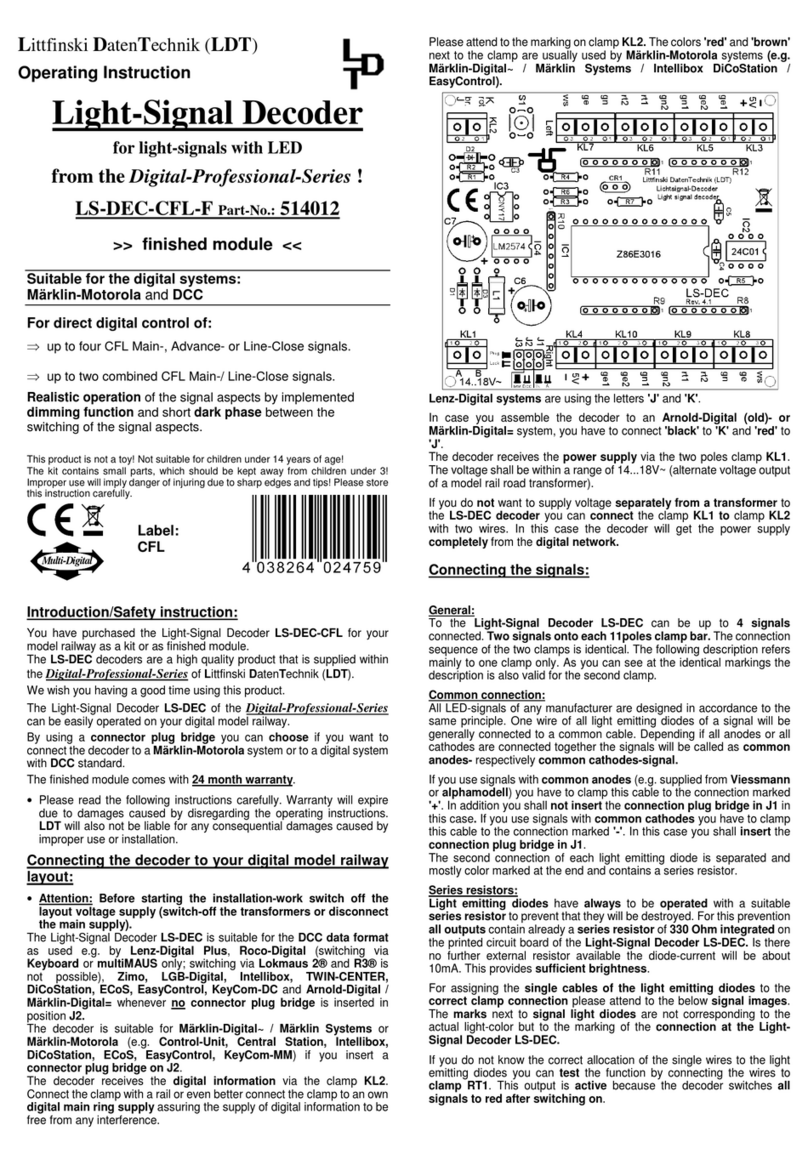

LDT LS-DEC-CFL-F User manual

LDT

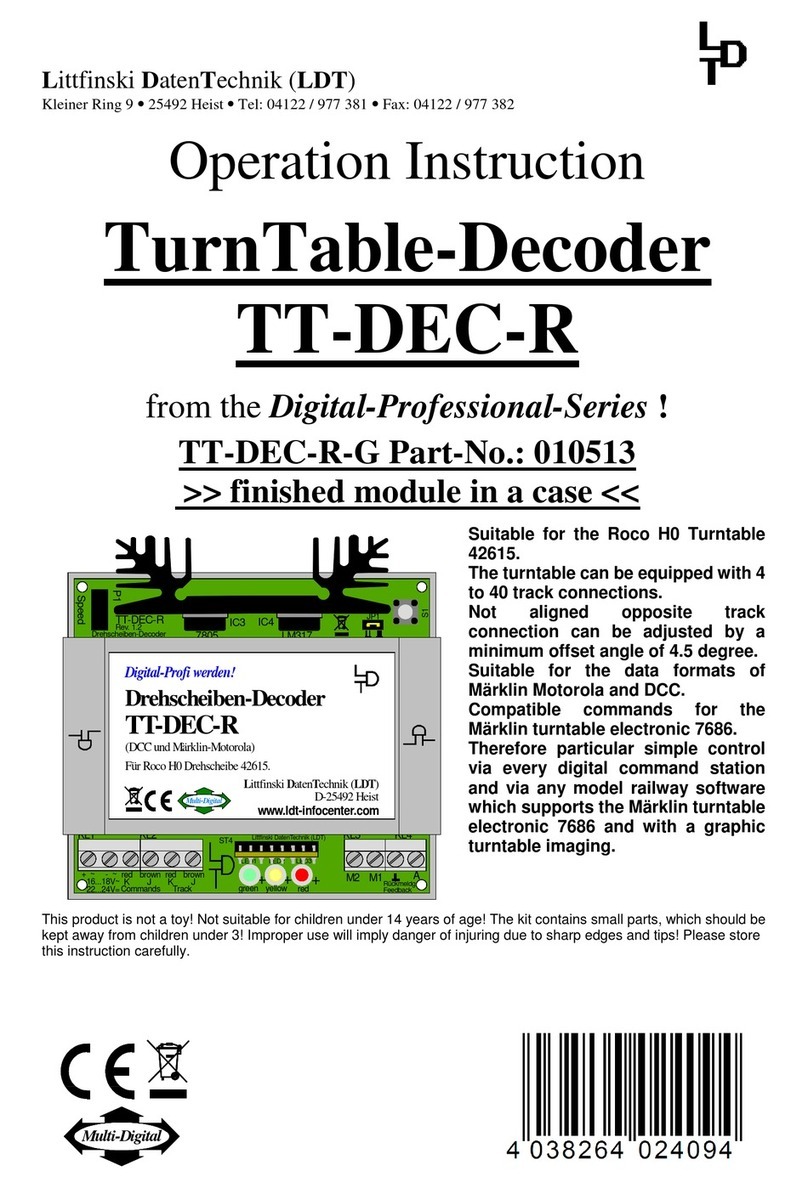

LDT TT-DEC-R User manual

LDT

LDT S-DEC-4-DC-G User manual

LDT

LDT LS-DEC-NS-F User manual

LDT

LDT SA-DEC-4-DC-G User manual

LDT

LDT SA-DEC-4-DC-G User manual

LDT

LDT SA-DEC-4-DC-B User manual

LDT

LDT LS-DEC Series User manual

LDT

LDT QS-DEC-II-F User manual

LDT

LDT Digital Professional Series User manual