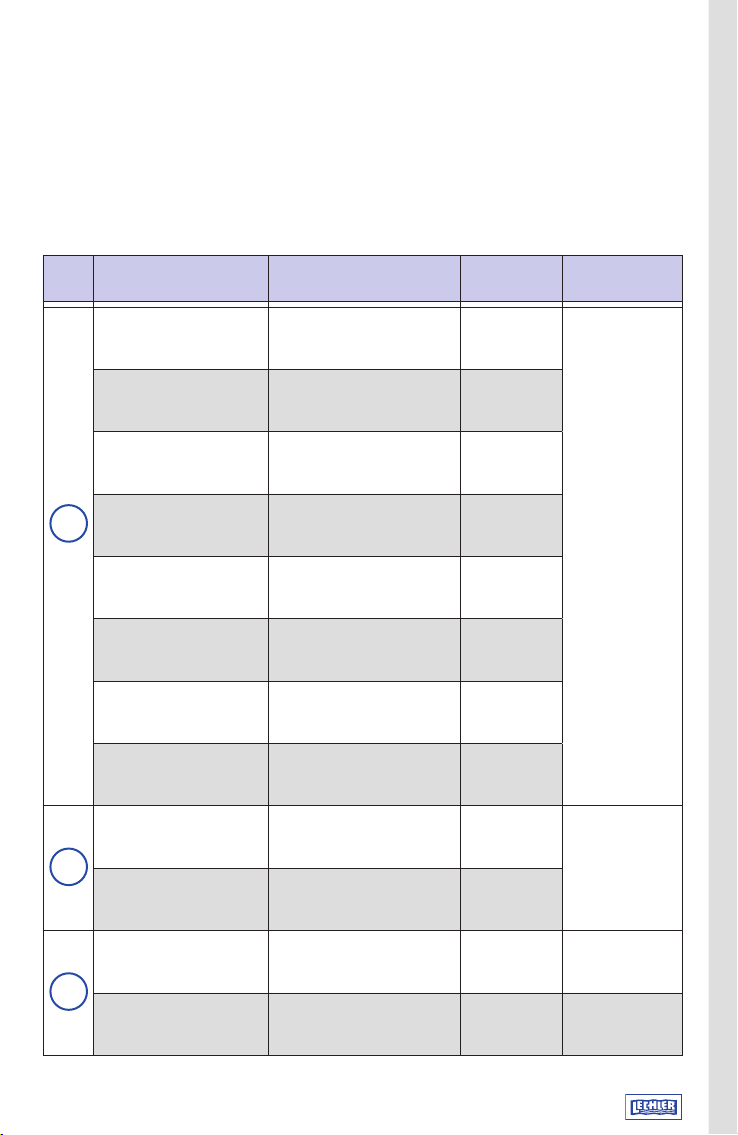

5

#19 - Hex Head Screw /

Sechskantschraube

5TC.000.1C.21.H0.0

Werkstoff: 1.4301

Material: 304

#36 - Cap / Kappe

5TC.000.1Y.33.V0.2

Werkstoff: 1.4404

Material: 316L

#35 - Cover / Deckel

5TM.000.1Y.33.C0.0

Werkstoff: 1.4404

Material: 316L

#15 - Cylinder Head Screw /

Zylinderschraube

5TC.000.1C.02.FR.0

Werkstoff: 1.4301

Material: 304

Gearbox / Getriebe

5TM.000.1Y.30.01.1

#9 - Shaft / Schaft

5TC.000.1Y.11.00.0

Werkstoff: 1.4404

Material: 316L

#34 - Cover / Deckel

5TC.000.1Y.31.00.0

Werkstoff: 1.4404

Material: 316L

#16 - Washer /

Unterlegscheibe

5TC.000.1Y.19.00.0

Werkstoff: 1.4404

Material: 316L

#32 - Bearing / Lager

5TM.000.T7.29.C0.0

Material: PEEK

#15 - Cylinder Head Screw /

Zylinderschraube

5TC.000.1C.02.FR.0

Werkstoff: 1.4301

Material: 304

#10 - Spur Gear / Zahnrad

5TM.000.1Y.12.13.0

Werkstoff: 1.4404

Material: 316L

#29 - Bushing / Buchse

5TM.000.C9.27.L0.0

Material: 316L [Hardened]

#27 - Nozzle Body / Düsenkörper

5TM.000.1Y.27.00.0

Werkstoff: 1.4404

Material: 316L

#25 - Ball Bearing / Kugellager

5TC.000.2R.26.BR.1

Material: PTFE + 302SS

#26 - Bearing Ring / Lagerring

5TC.000.C9.26.R0.0

Material: 316L [Hardened]

#19 - Hexagon Head Screw /

Sechskantschraube

5TC.000.1C.21.H0.0

Werkstoff: 1.4301

Material: 304

#18 - Gasket / Dichtung

5TC.000.55.21.G0.1

Material: PTFE

#21 - Nozzle / Düse

5TM.009.1Y.23.YS.0

Werkstoff: 1.4404

Material: 316L

#23 - Nozzle Seat / Düsenaufnahme

5TM.000.1Y.24.04.1

Werkstoff: 1.4404

Material: 316L

#24 - Grub Screw / Gewindestift

5TC.000.1Y.24.S0.0

Werkstoff: 1.4404

Material: 316L

#17 - Cover / Deckel

5TC.000.1Y.21.00.0

Werkstoff: 1.4404

Material: 316L

#20 - Bevel Gear / Kegelrad

5TC.000.1Y.22.00.0

Werkstoff: 1.4404

Material: 316L

#22 - Connecting Piece /

Verbindungsstück

5TC.000.1Y.24.C0.0

Werkstoff: 1.4404

Material: 316L

#30 - Bushing / Buchse

5TC.000.C9.27.H0.0

Material: 316L [Hardened]

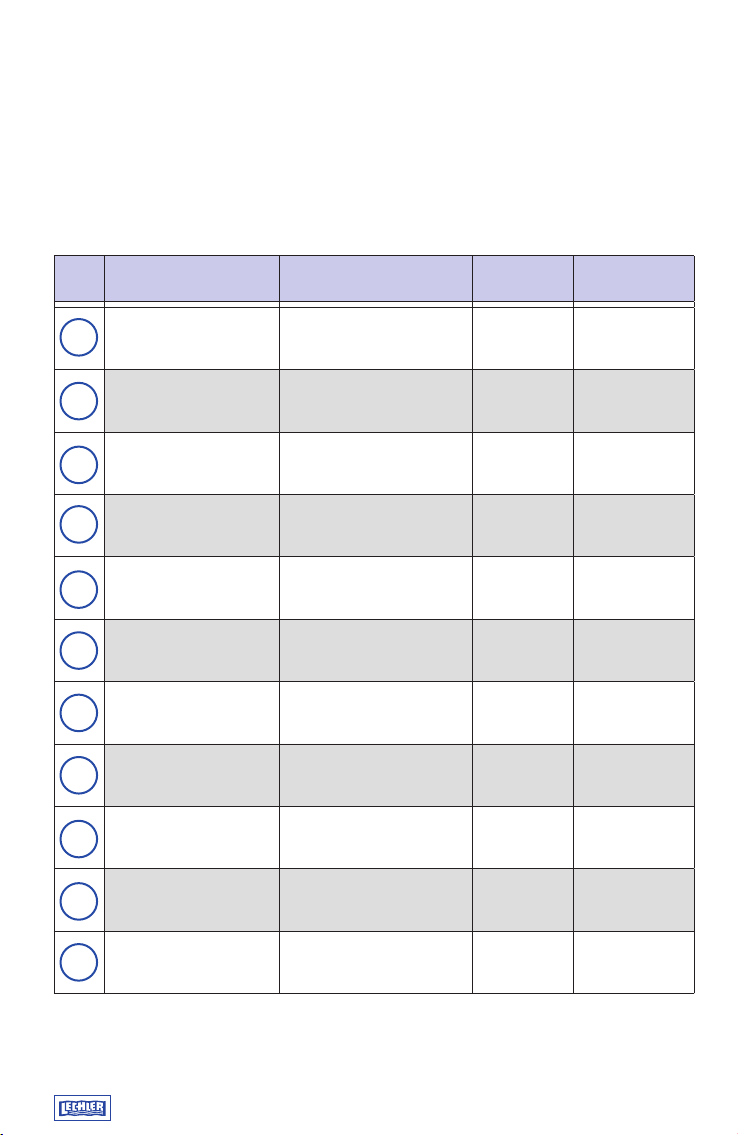

#6 - Bearing Ring / Lagerring

5TM.000.C9.26.R0.0

Material: 316L [Hardened]

#8 - Bushing / Buchse

5TM.000.T7.09.00.0

Material: PEEK

#5 - Ball / Kugel

5TM.000.R6.4V.R0.0

Material: 302SS

#28 - Bushing / Buchse

5TC.000.C9.27.U0.0

Material: 316L [Hardened]

#15 - Cylinder Head Screw /

Zylinderschraube

5TC.000.1C.02.FR.0

Werkstoff: 1.4301

Material: 304

#16 - Washer / Unterlegscheibe

5TC.000.1Y.19.00.0

Werkstoff: 1.4404

Material: 316L

#7 - Impeller / Flügelrad

5TC.000.1Y.05.00.0

Werkstoff: 1.4404

Material: 316L

#4 - Shaft / Schaft

5TC.000.1Y.04.00.0

Werkstoff: 1.4404

Material: 316L

#3 - Guide Wheel / Leitrad

5TC.000.1Y.03.00.0

Werkstoff: 1.4404

Material: 316L

#1 - 1-1/2" NPT

Connection Piece / Anschlussstück

5TM.000.1Y.02.BS.0

Werkstoff: 1.4404

Material: 316L

#2 - Cylinder Head Screw /

Zylinderschraube

5TC.000.1C.02.FS.0

Werkstoff: 1.4301

Material: 304