DELTA

Installation Manual

Edition July 2013

DELT

∆

∆∆

∆

platform lift page 8 of 24

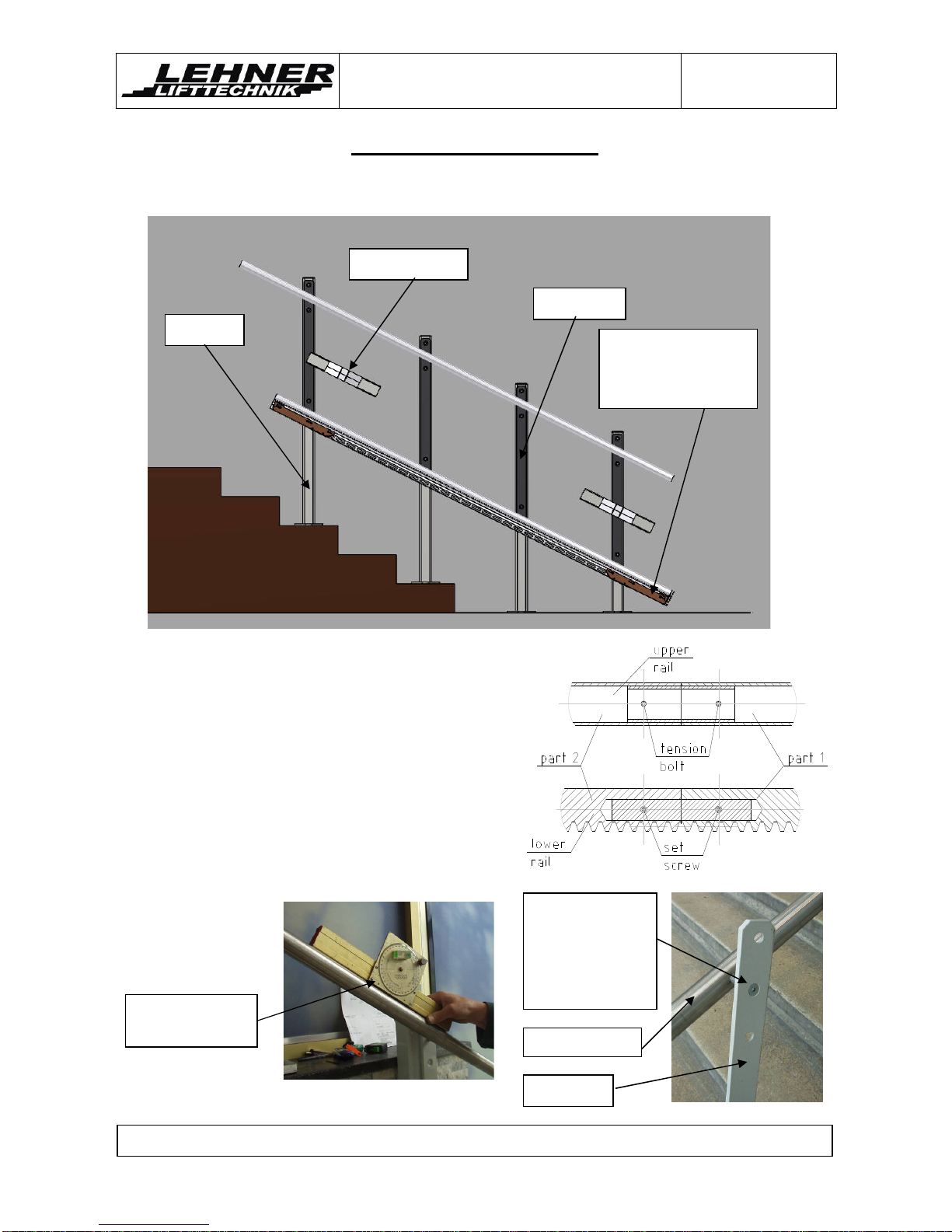

Installation of the platform onto the rail

If you wish to reduce the weight of the complete unit, you can dismantle the platform floor

from the carriage. Please see chapter “Changing the platform floor” for the detailed

explanation. If you can manage to lift the platform with 2 or more people continue as

outlined here elow:

Step 1: The upper charging station and the upper cam

have to e removed from the rail

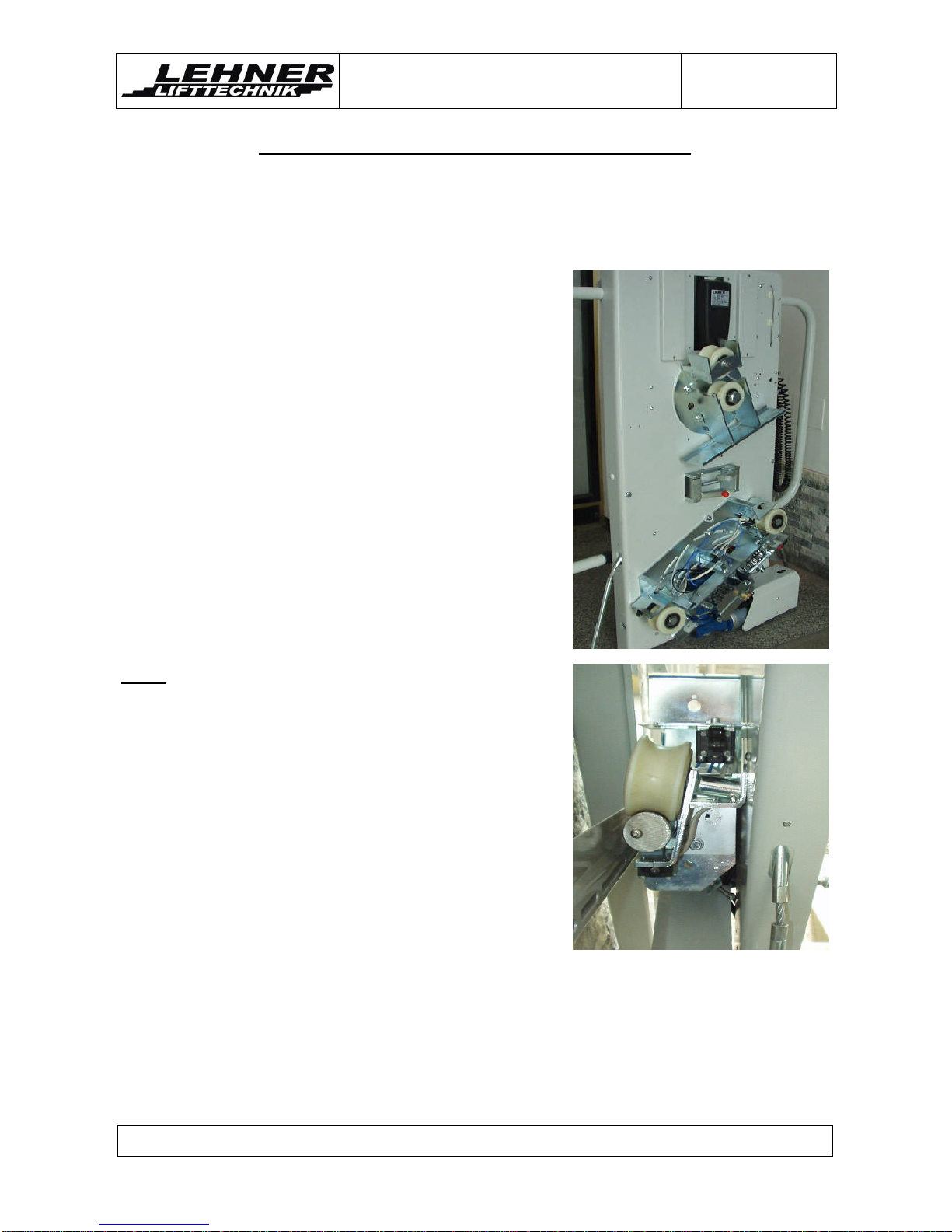

Step 2: Dismantle the covers from the upper and lower

carriages. The ackside of the sidewall should look as

shown on the picture eside.

Step 3: Carefully lift the carriage on upper rail end,

guiding the upper carriage rollers onto the upper rail.

Then the lower carriage will e approached carefully to

the lower rail.

Step 4: Insert the hand wheel into the drive motor,

loosen the reak of the motor and turn the hand wheel

into the downwards direction.

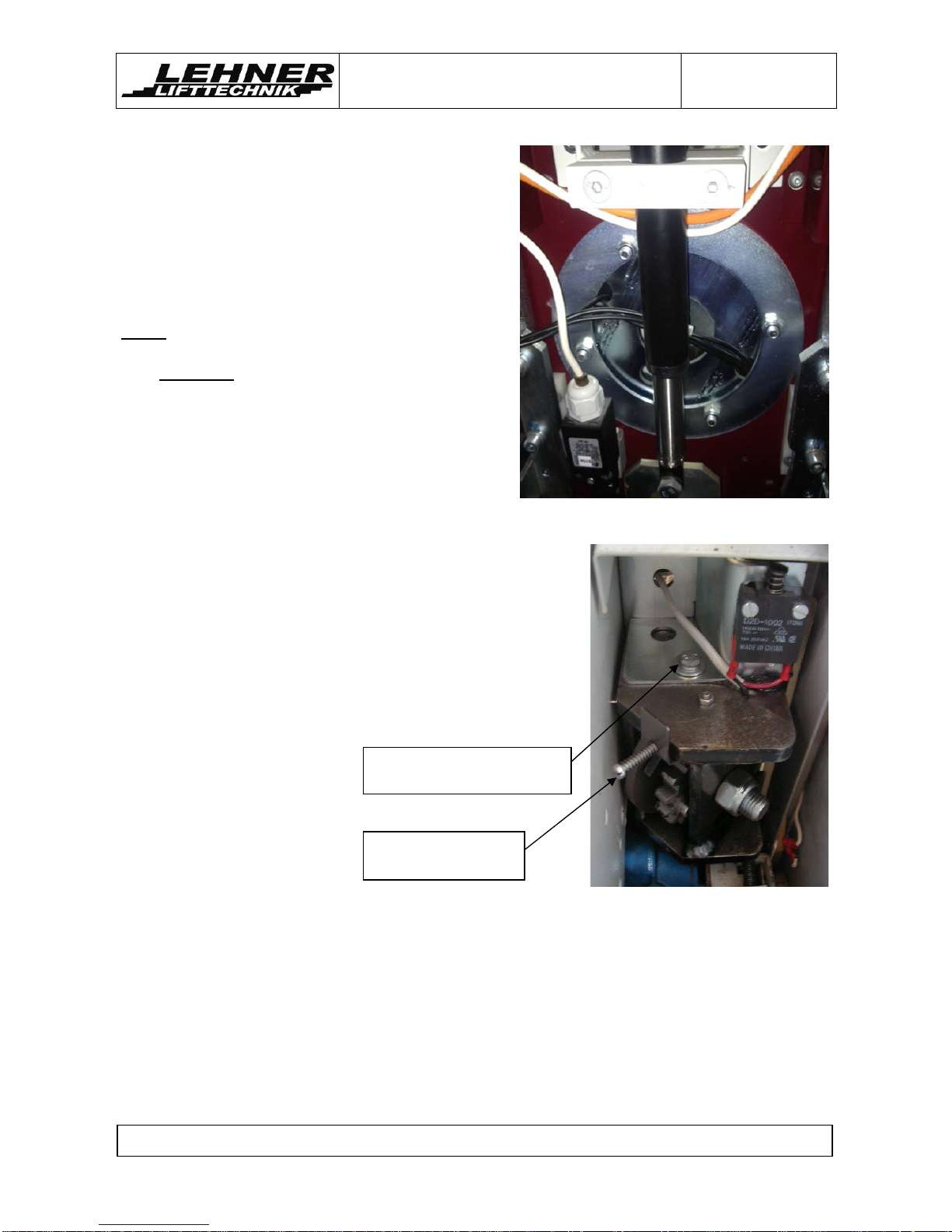

Note: Always watch the interference of the tooth wheels

(drive wheel and overspeed governor) and the rack.

Have a look at the illustration to the right – if it does not

go smoothly dismantle the platform again and insert it

new! Do not use the motor for riding the carriage onto

the rails! The tooth wheels of the drive and the

overspeed governor can e damaged!

Step 5: Install the atteries on the ackside of the

carriage (in case they have een removed). Check if the

attery is connected correctly and switch on the main

power switch.

Step 6: Open the platform carefully so that the arrier arms and platform floor are

horizontal. Now you can drive the platform further down y using the handset on spiral

ca le.