OMEGA Installation Manual

Omega platform lift page 5 of 46

Drill the mounting holes, starting at the bottom with

Pillar A and working up the system. In concrete, use

a 10 mm diameter masonry bit. Otherwise use a

dowel and drill a 12 mm hole!. When mounting in

wood, use a standard 6 mm wood drill. Pass the lag

bolt (screw materials like lag bolts, nuts, washers,

etc., are not included in Lehner-Lifttechnik delivery-

specification) through a washer, and screw it into the

end of a plug anchor. The anchor can then be

tapped into position using a small hammer. Avoid

spilling dust into the hole.

Check each connection for damage and lightly

grease both ends before joining the tube sections.

Fasten the connection with the splice bolts and nuts

provided.

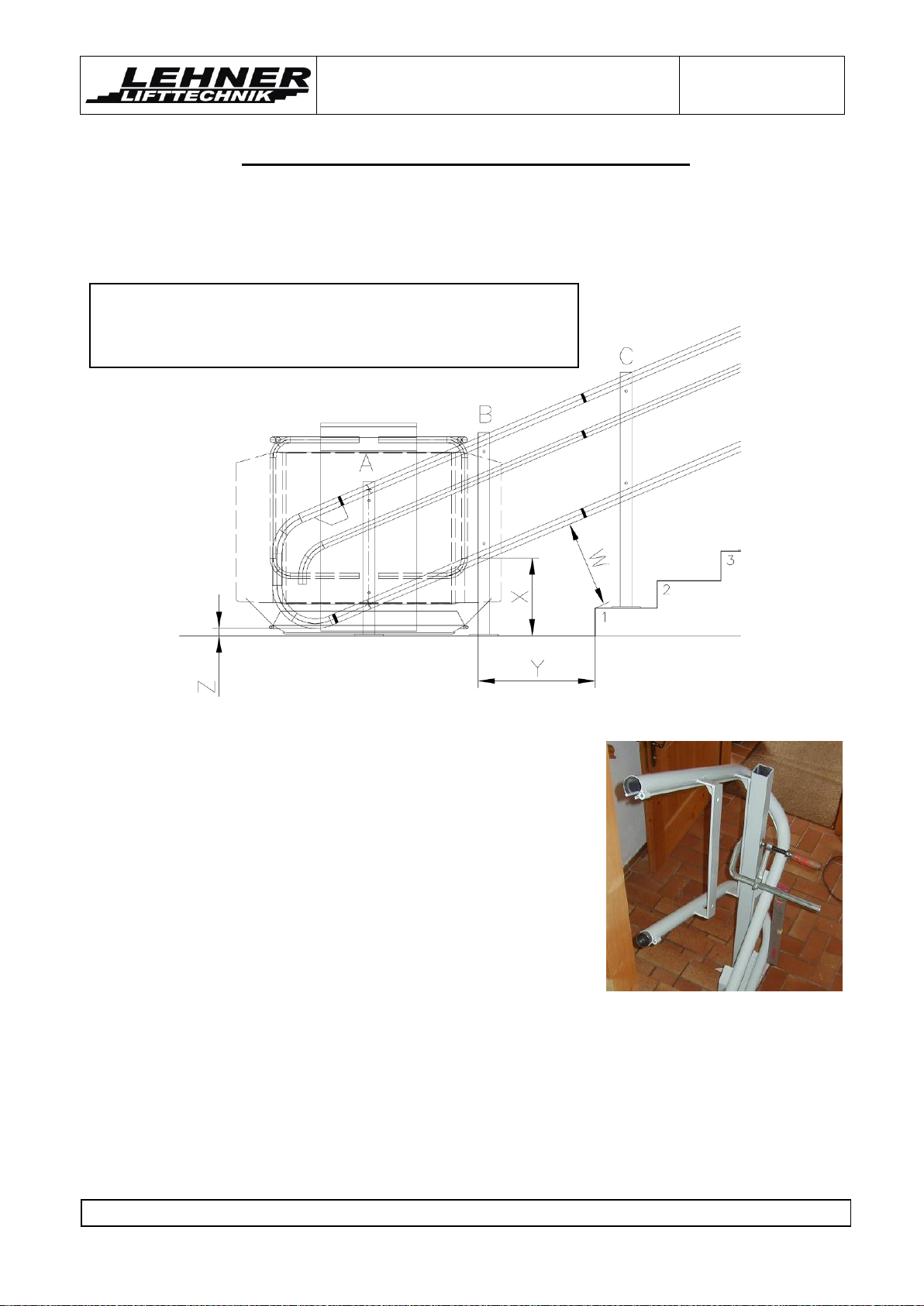

Check the clearance dimensions. Ensure that the

actual measurements correspond with the clearance

dimensions on the layout drawing.

Remember: Vertical clearances are measured from

the centreline of the tube (this is also the lower point

of the bracket on the railway) to the stair nose or to

the floor.

With the tubes in position, check all splice

connections for alignment. Note that the proper fit of

the splices is critical to ensure smooth lift operation.

When fixing the lift in place, smooth out any

misalignment using shims behind the mounting

struts.

On longer lifts some discrepancies may occur. Try

to average them out while making a final check for

landing clearances, splice alignment and fit.

With the system in place, check that all struts and

support pillars are plumb. Use a water level for this

work!

Clean any debris from the inside of the tubes.