EN

English Operating instructions 4

Contents

1. SEAMTEK W-AT............................................................................................................................................................ 4

1.1 Using this Manual ............................................................................................................................................... 4

2. Overview of Important Safety Instructions .................................................................................................................. 5

2.1 Important Safety Instructions ............................................................................................................................... 5

2.2 Intended Use ...................................................................................................................................................... 6

2.3 Improper Use...................................................................................................................................................... 6

2.4 Welding Vapors................................................................................................................................................... 6

2.4.1 Extraction ............................................................................................................................................... 6

2.5 Operating Modes ................................................................................................................................................ 6

2.6 Specialists and Training....................................................................................................................................... 6

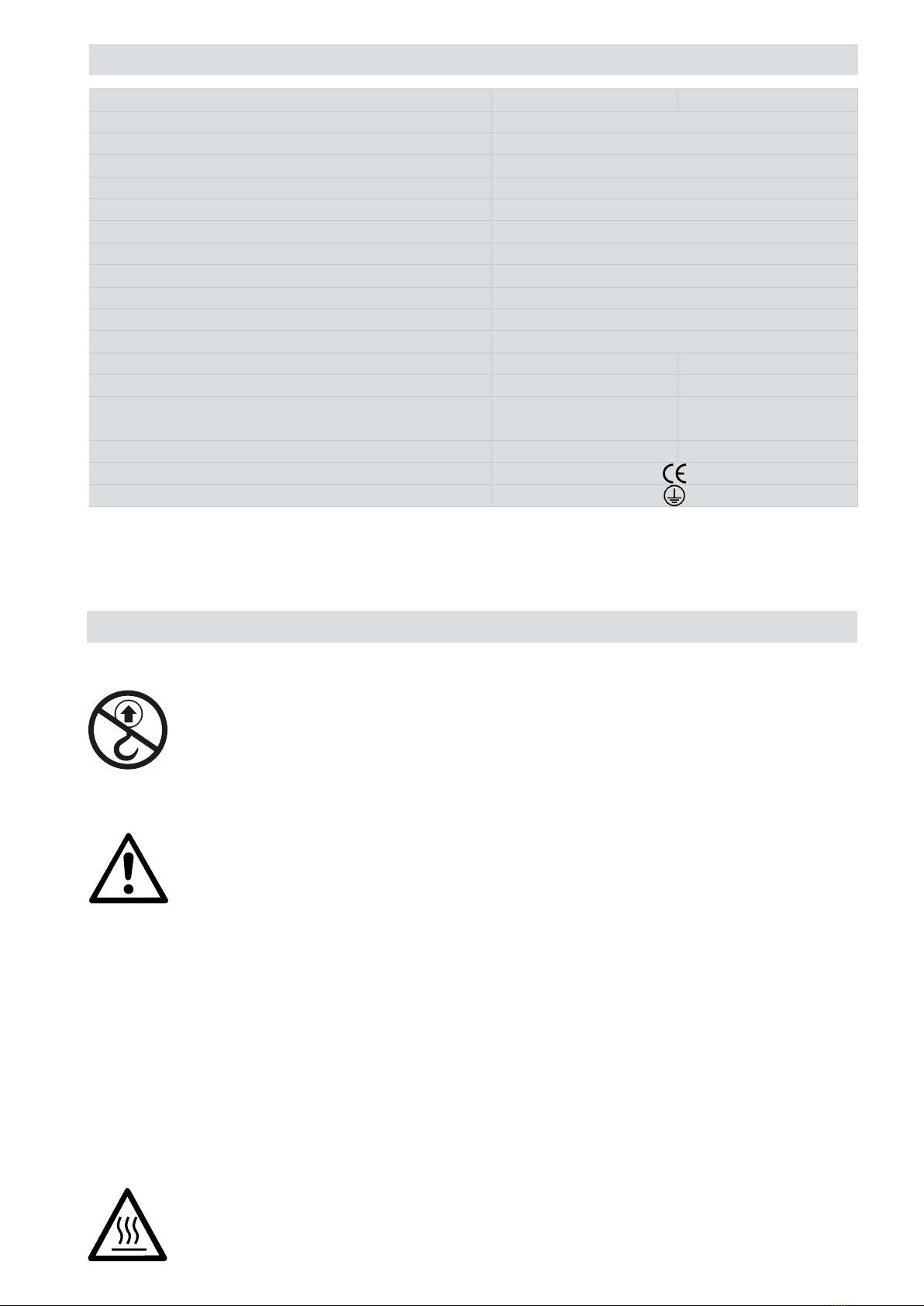

3. Technical Data ............................................................................................................................................................. 7

4. Transport and Commissioning ..................................................................................................................................... 7

4.1 Delivery.............................................................................................................................................................. 7

4.2 Unloading the Machine from the Transport Crate................................................................................................... 7

4.3 Transportation on the Company’s Premises........................................................................................................... 7

4.4 Transportation outside of the Company’s Premises................................................................................................ 8

4.5 Work Environment............................................................................................................................................... 8

4.6 Workplace and Workplace Environment................................................................................................................ 8

4.7 Securely Positioning the Machine......................................................................................................................... 9

4.8 Commissioning the Machine................................................................................................................................ 9

4.8.1 Power Supply.......................................................................................................................................... 9

5. Your SEAMTEK W-AT.................................................................................................................................................. 10

5.1 Type Plate and Identification .............................................................................................................................. 10

5.2 Scope of Delivery (standard model in transport box) ............................................................................................ 10

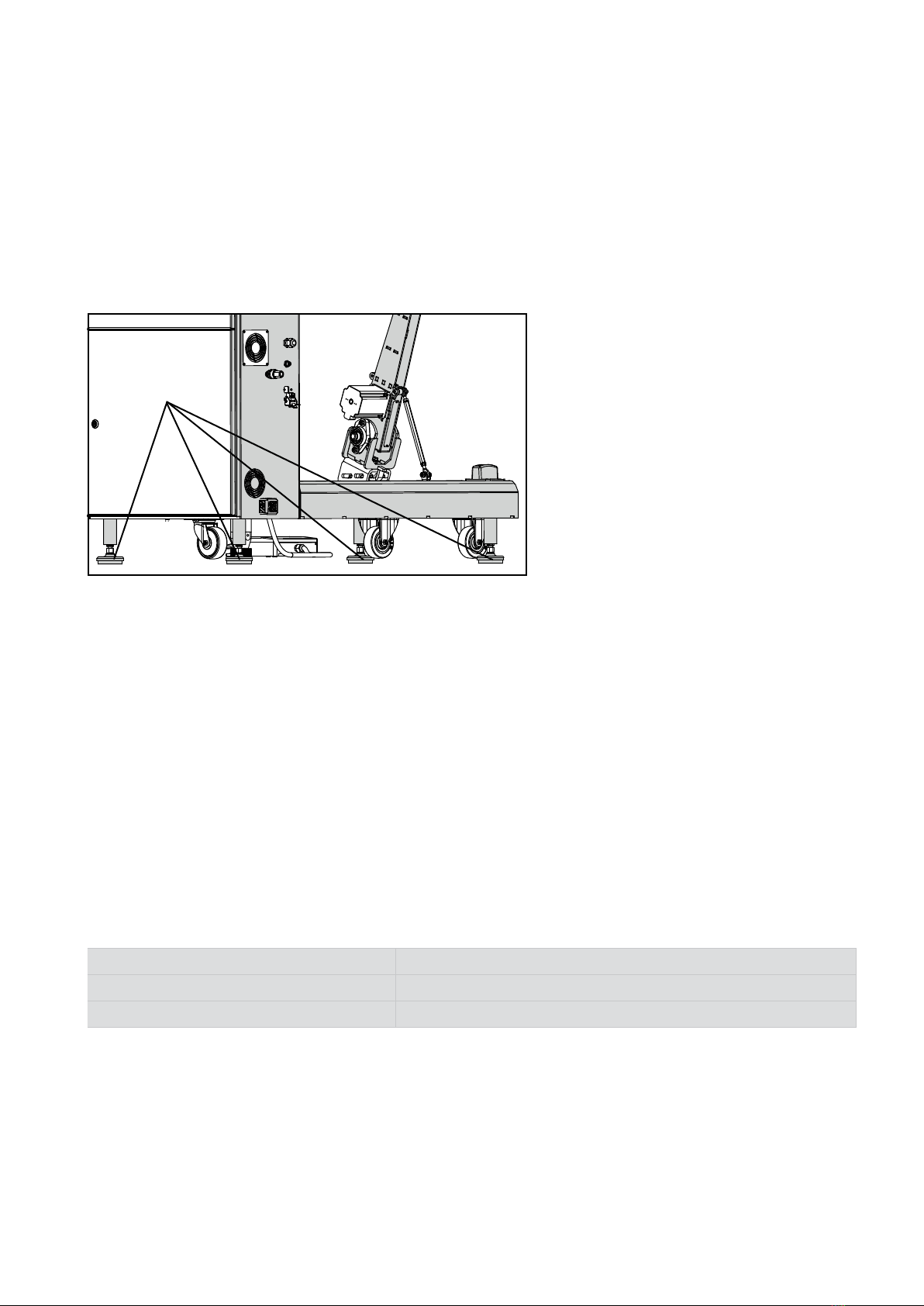

6. Overview of Machine Elements ................................................................................................................................. 11

6.1 Front View ........................................................................................................................................................ 11

6.2 Back View ........................................................................................................................................................ 12

6.3 Switch Cabinet.................................................................................................................................................. 12

6.4 Outlets for Accessories...................................................................................................................................... 12

6.5 Optional Accessories......................................................................................................................................... 13

6.5.1 Quickarm.............................................................................................................................................. 13

6.5.2 Tape Delivery System ............................................................................................................................ 13

7. Operation and Operating Elements............................................................................................................................ 13

7.1 Hot-Wedge Holder............................................................................................................................................. 13

7.2 Air Outlet for Switch Cabinet Cooling.................................................................................................................. 14

7.3 Touch Panel Operating Unit................................................................................................................................ 14

7.4 Emergency Stop Button ..................................................................................................................................... 14

7.4.1 Emergency Stop Button Function............................................................................................................ 15

7.5 USB Connection................................................................................................................................................ 15

7.6 Main Switch ..................................................................................................................................................... 15

7.7 Feet ................................................................................................................................................................. 16

7.8 Pedal Unit......................................................................................................................................................... 16

7.9 Changing Welding Arm and Welding Arm Options ............................................................................................... 17

7.9.1 Changing Welding Arm.......................................................................................................................... 17

7.9.2 Pedestal ............................................................................................................................................... 17

7.9.3 Quickarm.............................................................................................................................................. 18

7.10 Transport Rollers............................................................................................................................................... 18

7.10.1 Changing the Transport Rollers............................................................................................................... 19

7.11 Guide Holder..................................................................................................................................................... 20