6 - manual Lekker bikes manual Lekker bikes - 7

Chapter 1 | General warnings

Bicycling involves risk of injury, damage, or death. By choosing to ride a bicycle, you

assume the responsibility for that risk. Proper use and maintenance of your bicycle re-

duces risk of injury. This Manual contains many “Warnings” and “Cautions” concerning

the consequences of failure to maintain or inspect your bicycle and of failure to follow

safe cycling practices. It is impossible to anticipate every situation, or condition which

can occur while riding, this Manual makes no representation about the safe use of the

bicycle under all conditions. There are risks associated with the use of any bicycle which

cannot be predicted or avoided, and which are the sole responsibility of the rider.

MECHANICAL SAFETY

Check Routinely check the condition of your bicycle before every ride.

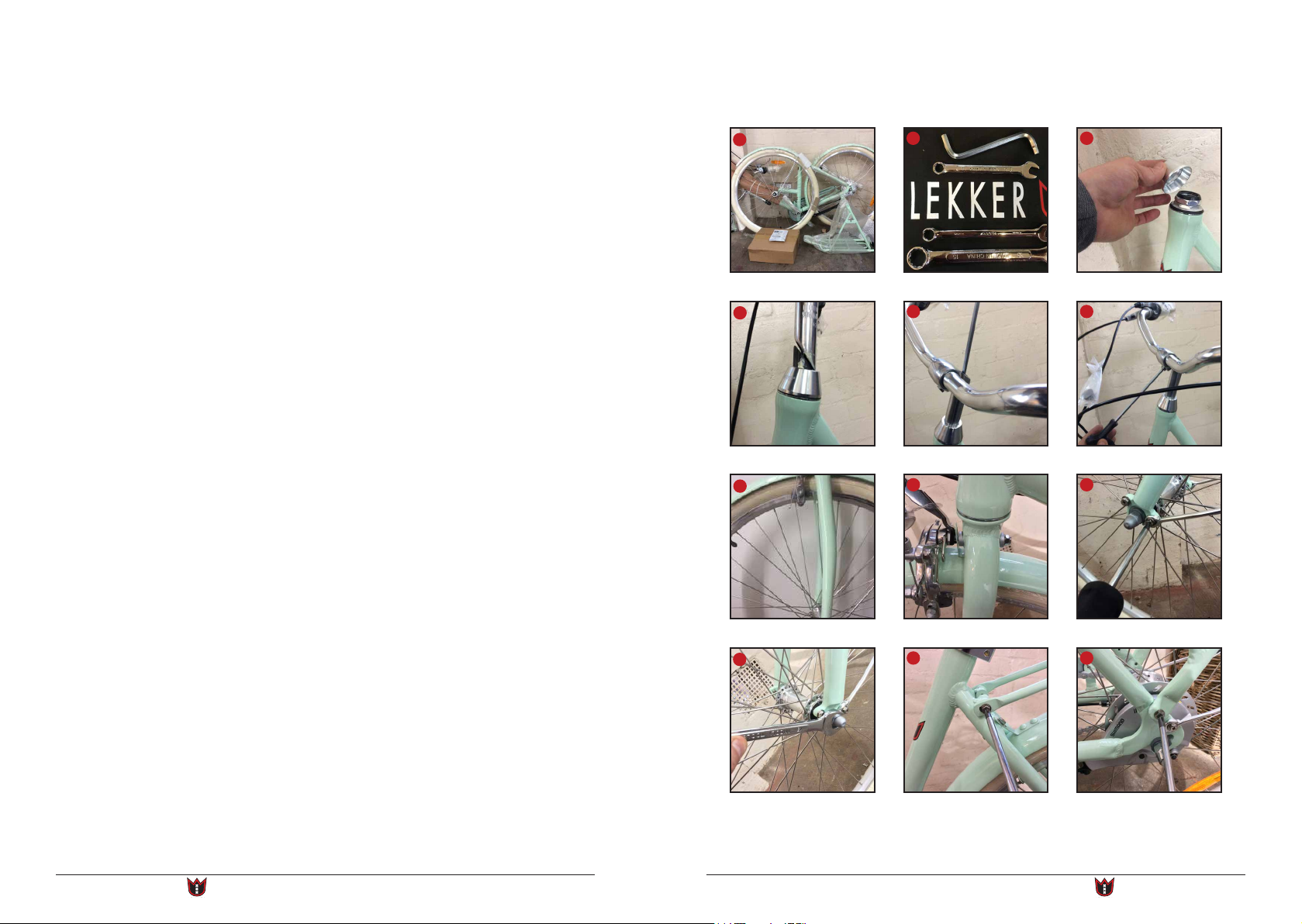

Nuts, bolts, screws & other fasteners: Because manufacturers use a wide variety of fas-

tener sizes and shapes made in a variety of materials, often differing by model and

component, the correct tightening force or torque cannot be generalized. To make sure

that the many fasteners on your bicycle are correctly tightened. Correctly tightening

a fastener requires a calibrated torque wrench. A professional bicycle mechanic with

a torque wrench should torque the fasteners on your bicycle. If you choose to work

on your own bicycle, you must use a torque wrench and the correct tightening torque

specifications from the bicycle or component manufacturer or from your dealer. If you

need to make an adjustment at home or in the field, we urge you to exercise care, and

to have the fasteners you worked on checked by your dealer as soon as possible.

WARNING

Correct tightening force on fasteners –nuts, bolts, screws– on your bicycle is important.

Too little force, and the fastener may not hold securely. Too much force, and the fas-

tener can strip threads, stretch, deform or break. Either way, incorrect tightening force

can result in component failure, which can cause you to lose control and fall. Make sure

nothing is loose. Lift the front wheel off the ground by two or three inches, then let it

bounce on the ground. Anything sound, feel or look loose? Do a visual and tactile in-

spection of the whole bike. Any loose parts or accessories? If so, secure them. If you’re

not sure, ask someone with experience to check.

TYRES & WHEELS

Make sure tyres are correctly inflated. Check by putting one hand on the saddle, one

on the intersection of the handlebars and stem, then bouncing your weight on the bike

while looking at tire deflection. Compare what you see with how it looks when you know

the tires are correctly inflated; and adjust if necessary. Tires in good shape? Spin each

wheel slowly and look for cuts in the tread and sidewall. Replace damaged tires before

riding the bike. Wheels true? Spin each wheel and check for brake clearance and side-

to-side wobble. If a wheel wobbles side to side even slightly, or rubs against or hits the

brake pads, take the bike to a qualified bike shop to have the wheel trued.

SEAT POST & HANDLEBAR ALIGNMENT

Check that the seat post is properly adjusted and that the seat post clamp is fastened to

the proper torque. Make sure the saddle and handlebar stem are parallel to the bike’s

center line and clamped tight enough so that you can’t twist them out of alignment.

CAUTION

Wheels must be true for rim brakes to work effectively. Wheel trueing is a skill which

requires special tools and experience. Do not attempt to true a wheel unless you have

the knowledge, experience and tools needed to do the job correctly. Wheel rims clean

and undamaged? Make sure the rims are clean and undamaged at the tire bead and, if

you have rim brakes, along the braking surface. Check to make sure that any rim wear

indicator marking is not visible at any point on the wheel rim.

WARNING

Bicycle wheel rims are subject to wear. Ask your dealer about wheel rim wear. Some

wheel rims have a rim wear indicator which becomes visible as the rim’s braking surface

wears. A visible rim wear indicator on the side of the wheel rim is an indication that the

wheel rim has reached its maximum usable life. Riding a wheel that is at the end of its

usable life can result in wheel failure, which can cause you to lose control and fall.

BRAKES

Check the brakes for proper operation. Squeeze the brake levers. Are the brake

quick-releases closed? All control cables seated and securely engaged? If you have rim

brakes, do the brake pads contact the wheel rim squarely and make full contact with

the rim? Do the brakes begin to engage within an inch of brake lever movement? Can

you apply full braking force at the levers without having them touch the handlebar? If

not, your brakes need adjustment. Do not ride the bike until the brakes are properly

adjusted by a professional bicycle mechanic.

HANDLEBAR ENDS

Make sure the handlebar grips are secure and in good condition. If not, have your deal-

er replace them. Make sure the handlebar ends and extensions are plugged. If not, have

your dealer plug them before you ride. If the handlebars have bar end extensions, make

sure they are clamped tight enough so you can’t twist them.

WARNING:

Loose or damaged handlebar grips or extensions can cause you to lose control and

fall. Unplugged handlebars or extensions can cut you and cause serious injury in an

otherwise minor accident.

This manual is not intended as a comprehensive use, service, repair or maintenance

manual. Please see a certified bicycle mechanic and dealer for all service, repairs or

maintenance. Your dealer may also be able to refer you to classes, clinics or books on

bicycle use, service, repair or maintenance.