NOTE: Use check boxes when Steps are completed.

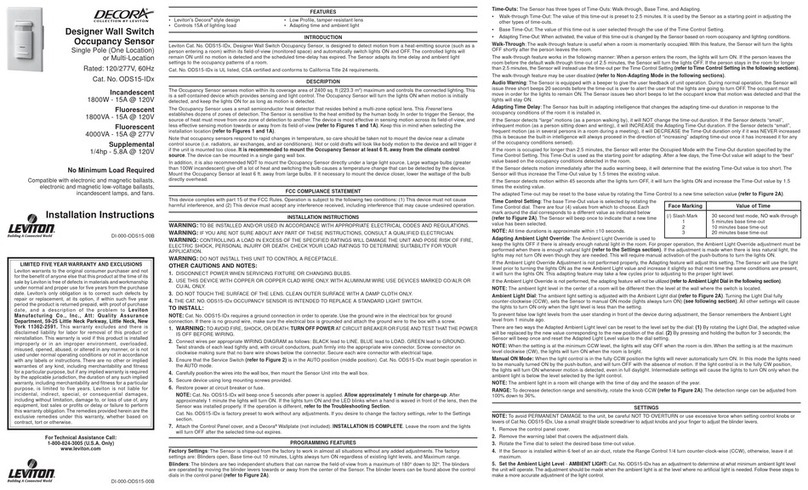

Infrared Ceiling Mounted Occupancy Sensor

California Title 20 Compliant

Cat. Nos. ODC

Ø

4-IDW, ODC15-IDW

No Minimum Load Required

Compatible with electronic and magnetic ballasts, electronic and magnetic low-voltage transformers, incandescent lamps, and fans

INSTALLATION INSTRUCTIONS

TOOLS NEEDED TO INSTALL YOUR SENSOR

DESCRIPTION

Slotted/Phillips Screwdriver Small Slotted Screwdriver Cutters Wire stripper

PARTS INCLUDED LIST

INSTALLING YOUR OCCUPANCY SENSOR

Sensor (1) 4" x 4" Mounting Plate (1) #6-32 x 1-1/2" Screw (2)

Mid-Range Lens (1) Emergency Label (1) Angled Light Pipe (1)

360˚ Perforated Mask (1) Low Voltage Connector (1) Half Mask (1)

Tubing Barrier (1)

The Occupancy Sensor is a LINE-voltage infrared sensor to automatically control lighting.

The sensor turns the lights ON and keeps them ON whenever occupancy is detected

and will turn them OFF after the "delayed-off time" has expired. The sensor continually

analyzes and adjusts to changing conditions. The sensor uses the latest microprocessor-

based technology which permits it to continually adjust and optimize its performance.

Infrared motion detection gives higher false triggering immunity that yields a sensor with

excellent performance.

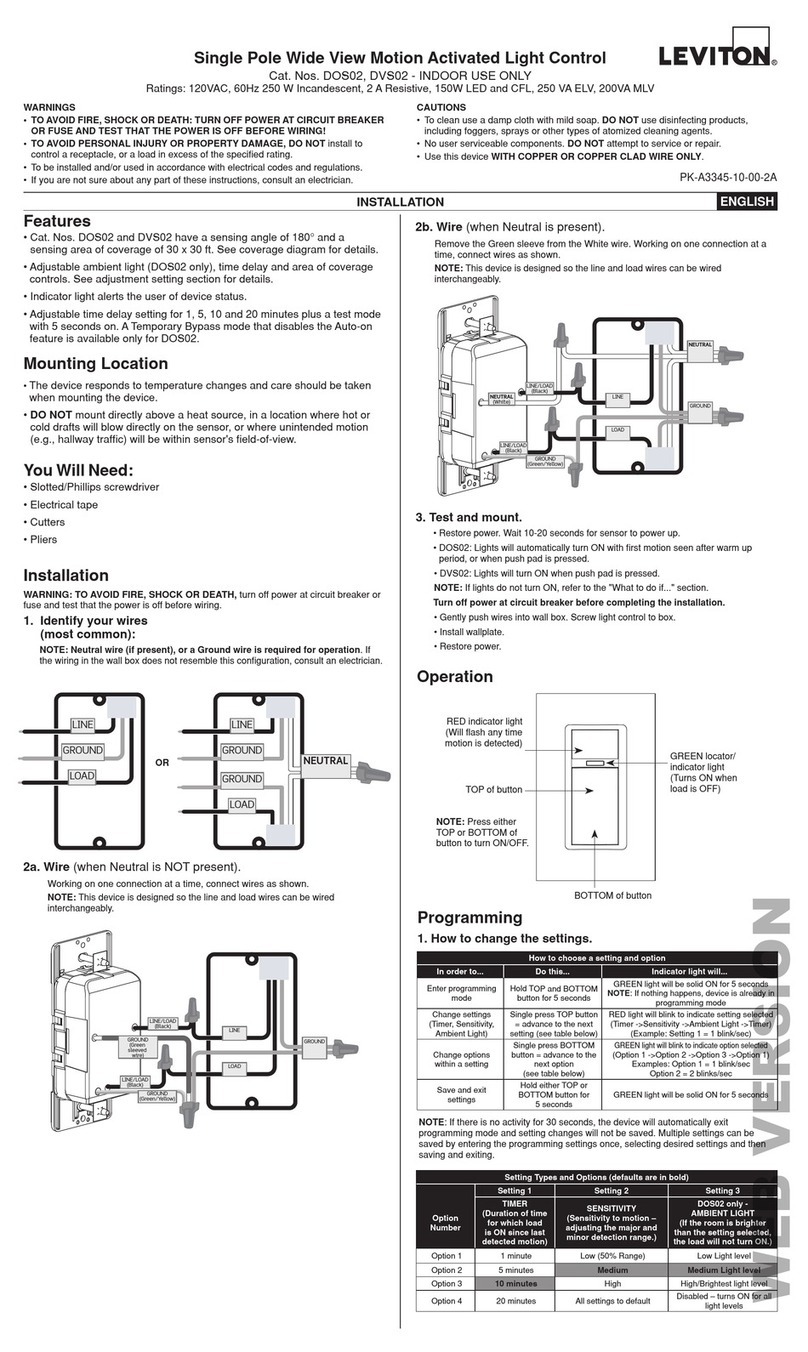

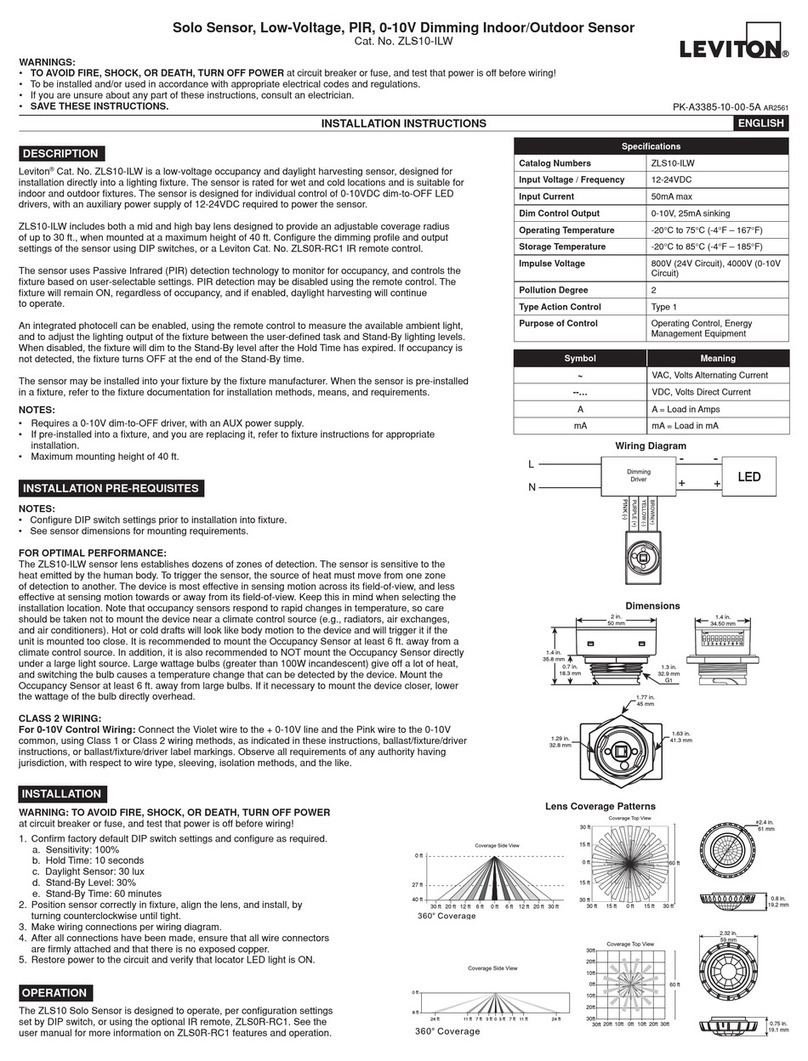

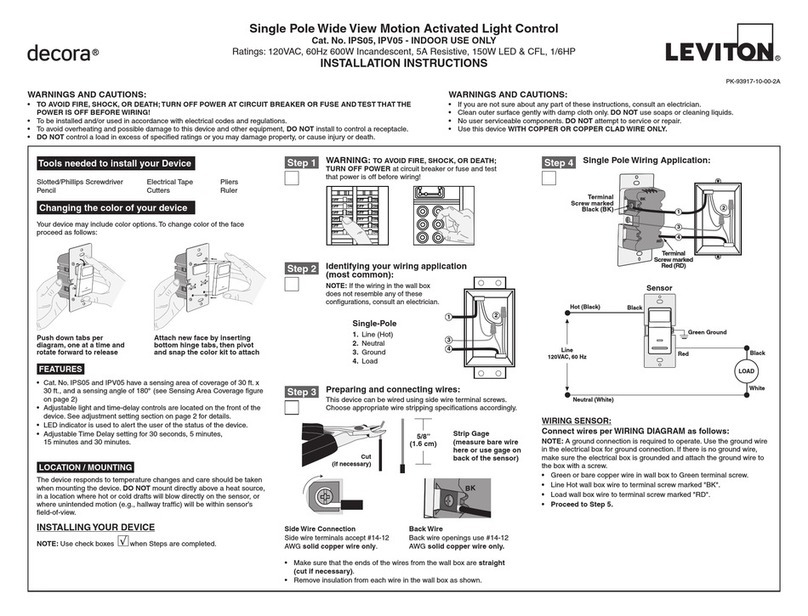

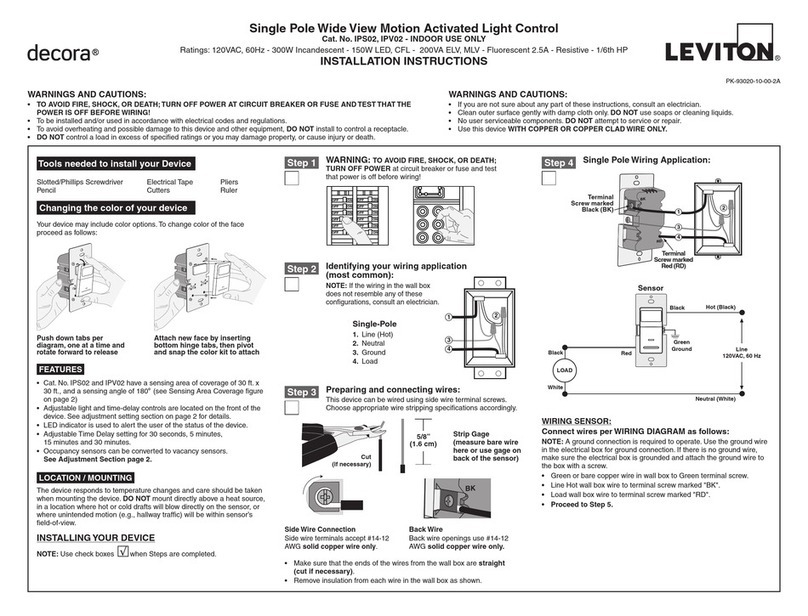

Wiring Sensor

Connect wires per WIRING DIAGRAM as follows:

1. Insert wires into proper terminals. Use a screwdriver to turn terminal screws

clockwise and secure wires.

a) Line wire to Line terminal.

b) Neutral wire to Neutral terminal.

c) Load wire to Load terminal.

d)

Manual Switch and Emergency Interface to their respective marked terminals.

NOTE: When wiring Manual Switch and Emergency Interface Class 2, use

the provided tubing for insulation inside the junction box.

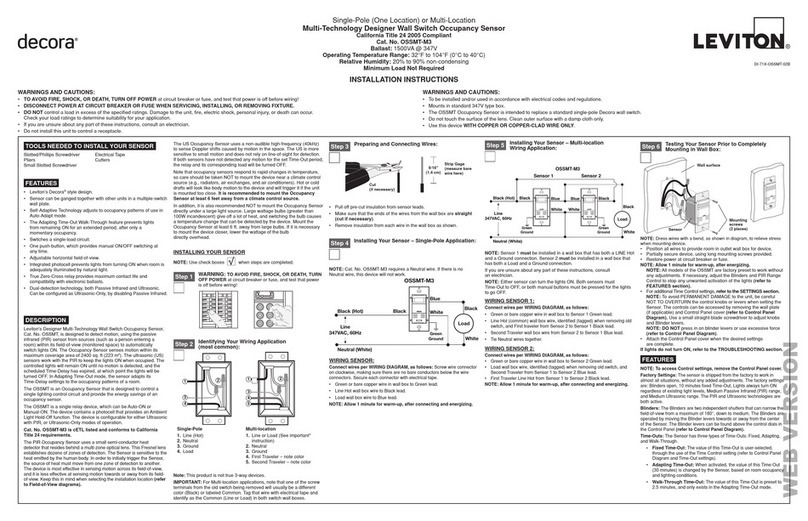

Mount Sensor in Electrical Box

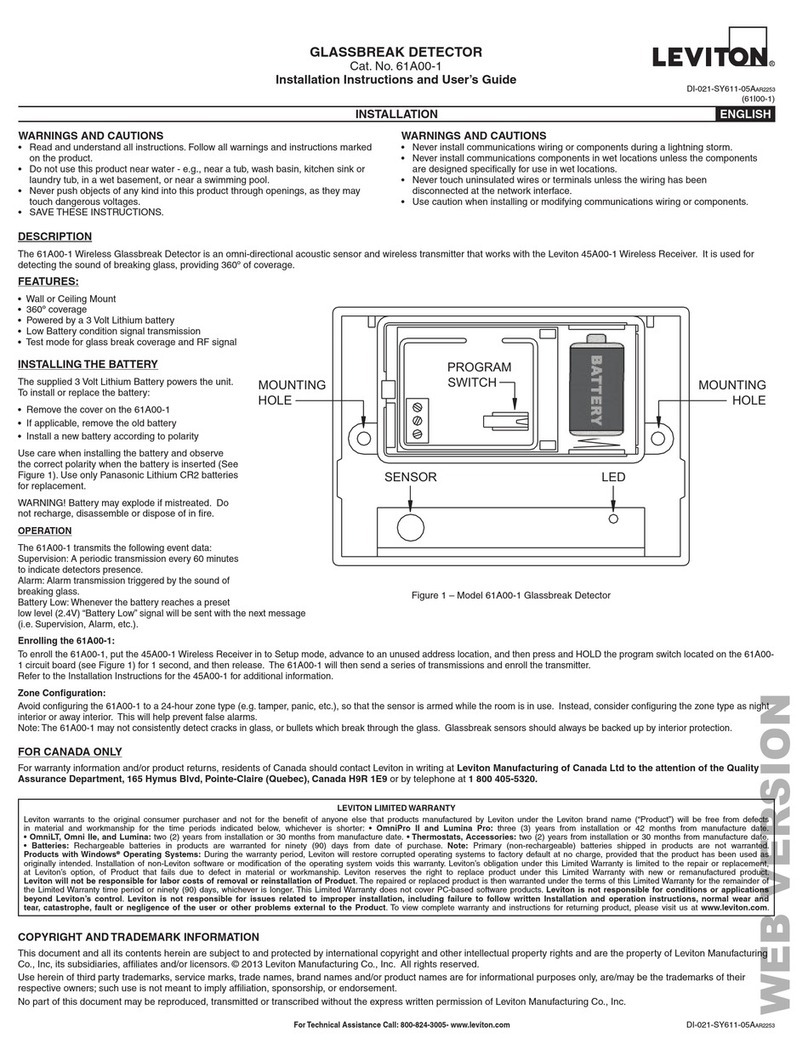

To mount inside 4" octagon 2.125" deep ceiling electrical box, refer to Figure 1.

•Dress line voltage wires to provide enough clearance in electrical box when

device is installed.

• Partiallythreadtwo#8-32screws(notincluded)intothemountingholesofthe

electrical box.

• Pulloutthetwocoastersthatalignwiththetwoscrews.

• Alignsensorsothatittsbetweenthemountingholesoftheelectricalboxand

insert over mounting screws.

• Pushinthetwocoastersthatalignwiththetwoscrews.

• Tightenmountingscrewsrmly.

MOUNT SENSOR IN ELECTRICAL BOX WITH MUD RING

To mount inside 4" square 1.5" deep ceiling electrical box with mud ring, refer to Figure 2 below.

• Ensure that conduit/cable entry clamp is located in corner of electrical box.

•Dress line voltage wires to provide enough clearance in electrical box when device is installed.

• Installatwo-gangmudring(notincluded)onelectricalbox.

• Partiallythreadthetwo#6-32screwsprovidedintothemountingholesoftheelectricalbox.

• Pulloutthetwocoastersthatalignwiththetwoscrews.

• Alignsensorsothatittsbetweenthemountingholesoftheelectricalboxandinsertover

mounting screws.

• Pushinthetwocoastersthatalignwiththetwoscrews.

• Tightenmountingscrewsrmly.

PK-93306-10-00-2A-X2

Figure 1

•

Make sure that the ends of the wires from the electrical box are straight (cut if necessary).

• Removeinsulationfromeachwireinelectricalboxasshown.

• WireperSpecications:

Line, Neutral, Load Wires (Copper)

Wire range:#12-18AWG,3.3-0.75mmsquare-Torque rating: 20 lb-in, 23 kgf-cm.

Control Wires (Manual Switch and Emergency Interface)

Wire range: #16-26 AWG, 4.0 - 0.12 mm square - Torque rating:2.5lb-in,2.88kgf-cm.

Preparing and connecting wires:

Cut

(if necessary)

3/4"

(1.9 cm)

Strip Gage

(measure bare

wire here)

Step 3

ONOFF

ONOFF

ONOFF

ONOFF

ONOFF

ONOFF

ONOFFONOFF

ONOFF

ONOFF

ONOFF

ONOFF

Step 1 WARNING: TO AVOID FIRE, SHOCK, OR

DEATH; TURN OFF POWER at circuit breaker

or fuse and TEST that power is off before wiring!

WARNINGS AND CAUTIONS:

• TO AVOID FIRE, SHOCK, OR DEATH; TURN OFF POWER AT CIRCUIT BREAKER OR FUSE AND

TEST THAT POWER IS OFF BEFORE WIRING!

• Tobeinstalledand/orusedinaccordancewithappropriateelectricalcodesandregulations.

• Ifyouareunsureaboutanypartoftheseinstructions,consultanelectrician.

• Sensorsmustbemountedonavibrationfreesurface.

• Donotterminateusingdatatypewire,suchasCat5/5E.

• Donotmountsensorscloserthan10feettoeachother.

• Allsensorsmustbemountedatleast6feetawayfromairvents,airhandlers,andreectivesurfaces

(windows/mirrors).

• Donottouchthesurfaceofthelens.Cleanoutersurfacewithadampclothonly.

WARNINGS AND CAUTIONS:

For Occupancy Sensors installed to control Emergency Lighting Equipment:

If this equipment is being used for Emergency Lighting and Power Equipment, please adhere to the following information. This equipment

is rated for only 25C if used on Emergency Lighting Equipment. Apply the "Emergency Circuits" label (provided) to the front cover.

IMPORTANT SAFEGUARDS

When using electrical equipment, basic safety precautions should always be followed, including the following:

a) READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

b) DO NOT use outdoors.

c) DO NOT mount near gas or electric heaters.

d) Equipment should be mounted in locations and at heights where it will not readily be subjected to tampering by unauthorized personnel.

e) The use of accessory equipment not recommended by manufacturer may cause an unsafe condition.

f) DO NOT use this equipment for other than the intended use.

SAVE THESE INSTRUCTIONS

Allservicingshallbeperformedbyqualiedservicepersonnel.IfanyEmergencyCircuitsarefedorcontrolledfromthispanel,itmustbe

located electrically where fed from a UPS, generator, or other guaranteed source of power during emergencies and power outage situations.

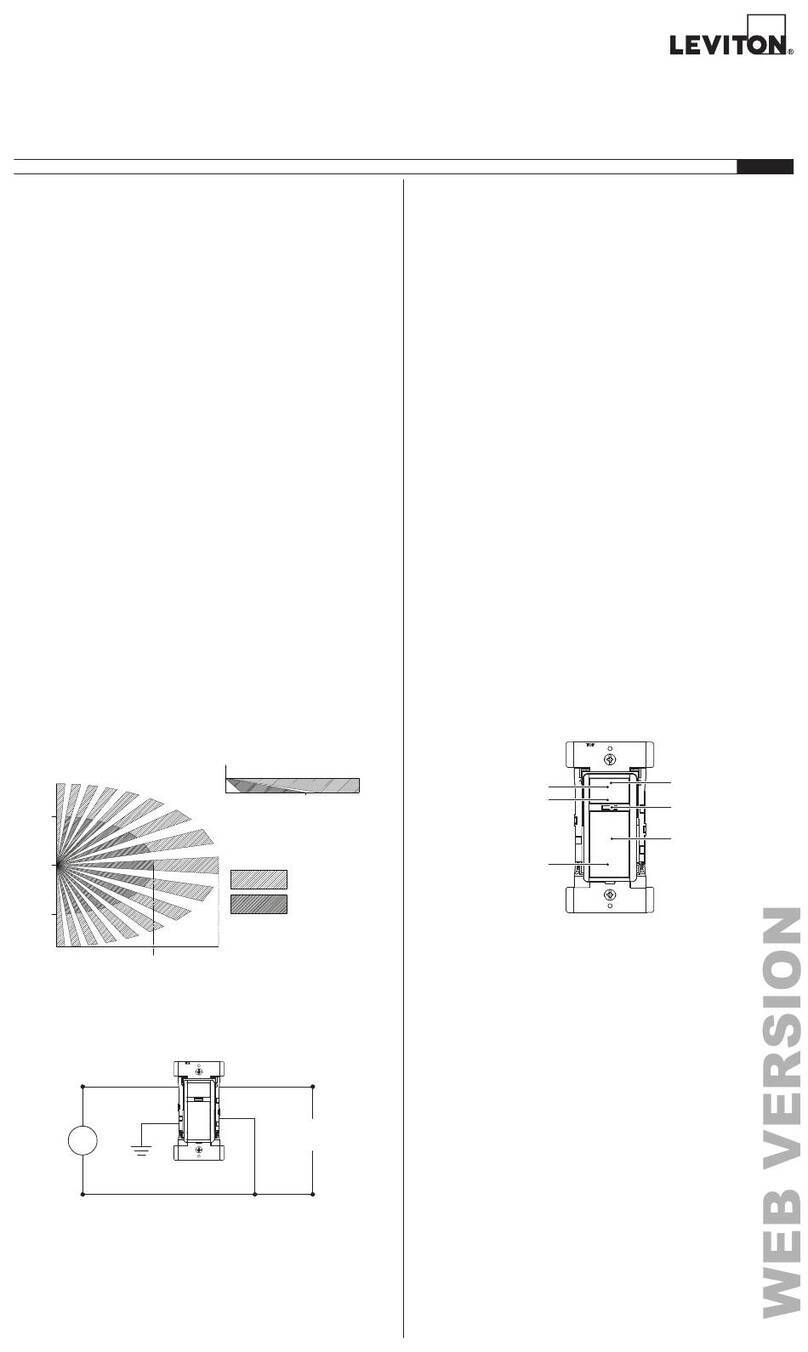

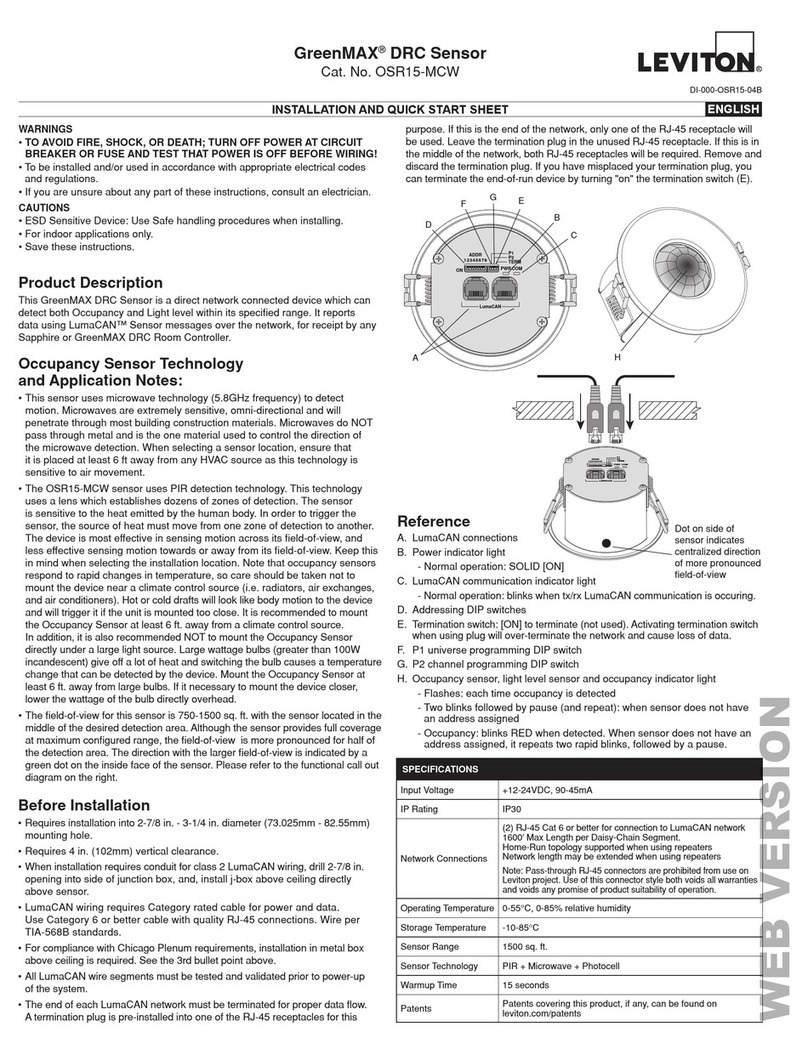

Mount in center of

room/area,8-12ftheight

Mount in center of

room/area,8-12ftheight

Suggested Mounting Location

450 sq. ft.

1500 sq. ft.

Coverage

ODC04-IDW

ODC15-IDW

Cat. No.

High

Density

Extended

Range

Description

120-277,50/60Hz

120-277,50/60Hz

Voltage Range

60-30ma

60-30ma

Current Consumption

CATALOG ITEMS

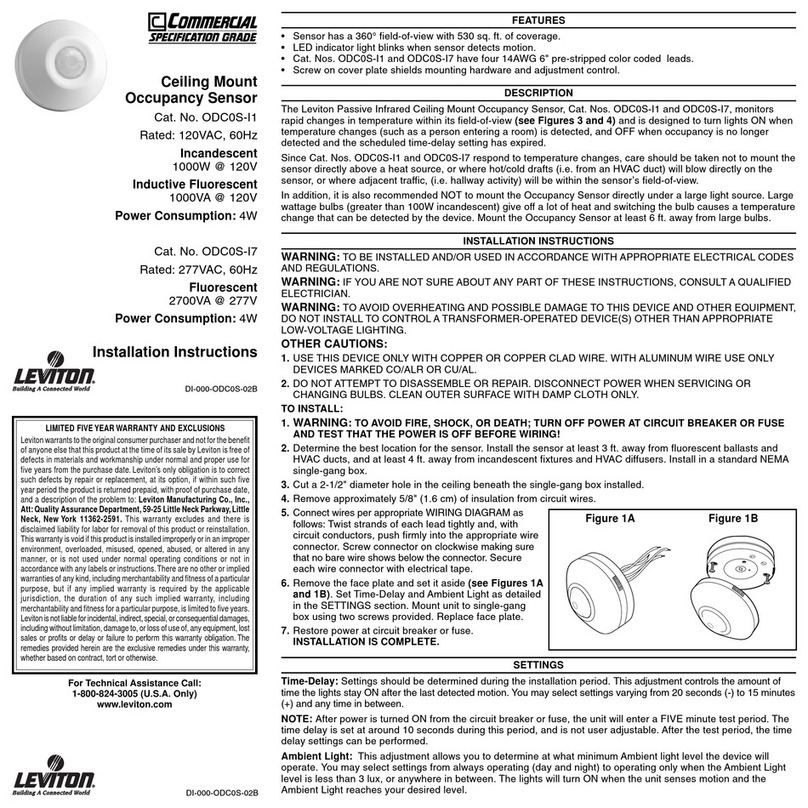

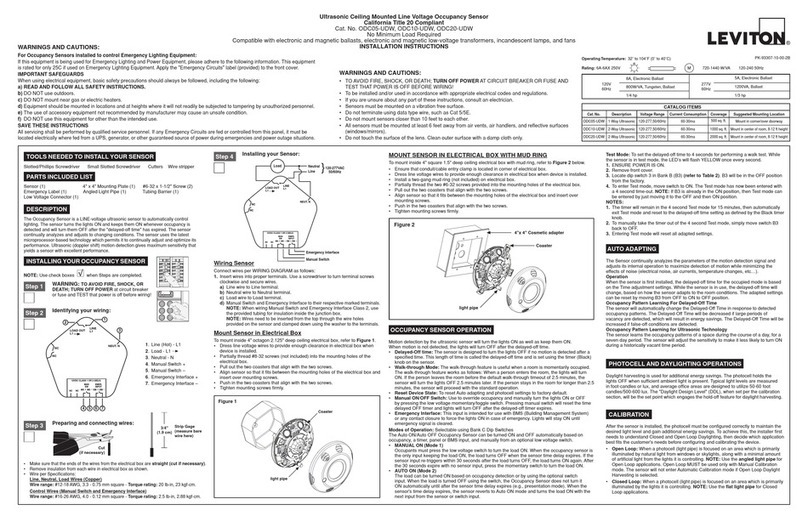

Identifying your wiring:

Step 2

4 5 6 7

3

1

2

LOAD OUT

L1

LINE

L1

NEUT. N

NC

NC

12VDC CLASS 1 OR 2 (SELV)

MAN

SW

NC NC MS +–+–

MS EM EM

EMER.

INPUT

Installing your Sensor:

Step 4

12VDC CLASS 1 OR 2 (SELV)

MAN

SW

NC NC MS +–+–

MS EM EM

EMER.

INPUT

Emergency Interface

Neutral 120-277VAC

50/60Hz

}

Line

Manual Switch

Load

LOAD OUT

L1

LINE

L1

NEUT. N

NC

NC

PHOTOCELL AND DAYLIGHTING OPERATIONS

Daylight harvesting is used for additional energy savings. The photocell holds the

lightsOFFwhensufcientambientlightispresent.Typicallightlevelsaremeasured

infoot-candlesorlux,andaverageofceareasaredesignedtoutilize50-60foot

candles/500-600 lux. The "Daylight Design Level" (DDL), when set per the calibration

section, will be the set point which engages the hold-off feature for daylight harvesting.

120V

60Hz

277V

60Hz

800W/VA,Tungsten,Ballast

8A,ElectronicBallast

1/4 hp

1200VA, Ballast

5A, Electronic Ballast

1/3 hp

Rating: 6A-6AX 250V

Operating Temperature: 32˚ to 104˚F (0˚ to 40˚C)

720-1440W/VA 120-240 50HzM

CALIBRATION

Afterthesensorisinstalled,thephotocellmustbeconguredcorrectlytomaintainthe

desiredlightlevelandgainadditionalenergysavings.Toachievethis,theinstallerrst

needs to understand Closed and Open Loop Daylighting, then decide which application

besttsthecustomer'sneedsbeforeconguringandcalibratingthedevice.

• Open Loop: When a photocell (light pipe) is focused on an area which is primarily

illuminated by natural light from windows or skylights, along with a minimal amount

ofarticiallightfromthelightsitiscontrolling.NOTE: Use the angled light pipe for

Open Loop applications. Open Loop MUST be used only with Manual Calibration

mode. The sensor will not enter Automatic Calibration mode if Open Loop Daylight

Harvesting is selected.

• Closed Loop: When a photocell (light pipe) is focused on an area which is primarily

illuminated by the lights it is controlling. NOTE: Use the flat light pipe for Closed

Loop applications.

Figure 2

1. Line (Hot) - L1

2. Load - L1

3. Neutral - N

4. Manual Switch +

5. Manual Switch –

6. Emergency Interface +

7. Emergency Interface –

OCCUPANCY SENSOR OPERATION

Motion detection by the infrared sensor will turn the lights ON as well as keep them ON.

When motion is not detected, the lights will turn OFF after the delayed-off time.

• Delayed-Off time: The sensor is designed to turn the lights OFF if no motion is detected after a

speciedtime.Thislengthoftimeiscalledthedelayed-offtimeandissetusingthetimer(Black)

knob on the sensor.

• Walk-through Mode: The walk-through feature is useful when a room is momentarily occupied.

The walk-through feature works as follows: When a person enters the room, the lights will turn

ON. If the person leaves the room before the default walk-through timeout of 2.5 minutes, the

sensor will turn the lights OFF 2.5 minutes later. If the person stays in the room for longer than 2.5

minutes, the sensor will proceed with the standard operation.

• Reset Device State: To reset Auto adapting and photocell settings to factory default.

• Manual ON/OFF Switch: Use to override occupancy and manually turn the lights ON or OFF

by pressing the low voltage momentary/toggle switch. Pressing manual switch will reset the time

delayed OFF timer and lights will turn OFF after the delayed-off timer expires.

• Emergency Interface: This input is intended for use with BMS (Building Management System)

or any contact closure to force the lights ON in case of emergency. Lights will stay ON until

emergency signal is cleared.

Modes of Operation: Selectable using Bank C Dip Switches

The Auto ON/Auto OFF Occupancy Sensor can be turned ON and OFF automatically based on

occupancy, a timer, panel or BMS input, and manually from an optional low voltage switch.

• MANUAL ON (Mode 1)

Occupants must press the low voltage switch to turn the load ON. When the occupancy sensor is

the only input keeping the load ON, the load turns OFF when the sensor time delay expires. If the

sensor input re-triggers within 30 seconds after the load turns OFF, the load turns ON again. After

the 30 seconds expire with no sensor input, press the momentary switch to turn the load ON.

• AUTO ON (Mode 2)

The load can be turned ON based on occupancy detection or by using the optional switch

input. When the load is turned OFF using the switch, the Occupancy Sensor does not turn it

ON automatically until after the sensor time delay expires (e.g., presentation mode). When the

sensor'stimedelayexpires,thesensorrevertstoAutoONmodeandturnstheloadONwiththe

next input from the sensor or switch input.

AUTO ADAPTING

The Sensor continually analyzes the parameters of the motion detection signal and

adjusts its internal operation to maximize detection of motion while minimizing the

effects of noise (electrical noise, air currents, temperature changes, etc…).

Operation

Whenthesensorisrstinstalled,thedelayed-offtimefortheoccupiedmodeisbased

on the Time adjustment settings. While the sensor is in use, the delayed-off time will

change, based on how the sensor adapts to the room conditions. The adapted settings

can be reset by moving B3 from OFF to ON to OFF position.

Occupancy Pattern Learning For Delayed-Off Time

The sensor will automatically change the Delayed-Off Time in response to detected

occupancy patterns. The Delayed-Off Time will be decreased if large periods of

vacancy are detected, which will result in energy savings. The Delayed-Off Time will be

increased if false-off conditions are detected.

Occupancy Pattern Learning for Infrared Technology

The sensor learns the occupancy patterns of a space during the course of a day, for a

seven day period. The sensor will adjust the sensitivity to make it less likely to turn ON

during a historically vacant time period.

Test Mode: To set the delayed-off time to 4 seconds for performing a walk test. While

thesensorisintestmode,theLEDwillashYELLOWonceeverysecond.

1. ENSURE POWER IS ON.

2. Remove front cover.

3. Locate dip switch 3 in Bank B (B3) (refer to Table 2). B3 will be in the OFF position

from the factory.

4. To enter Test mode, move switch to ON. The Test mode has now been entered with

a 4 second time-out. NOTE: If B3 is already in the ON position, then Test mode can

be entered by just moving it to the OFF and then ON position.

NOTES:

1. The timer will remain in the 4 second Test mode for 15 minutes, then automatically

exitTestmodeandresettothedelayed-offtimesettingasdenedbytheBlacktimer

knob.

2. To manually take the timer out of the 4 second Test mode, simply move switch B3

back to OFF.

3. Entering Test mode will reset all adapted settings.

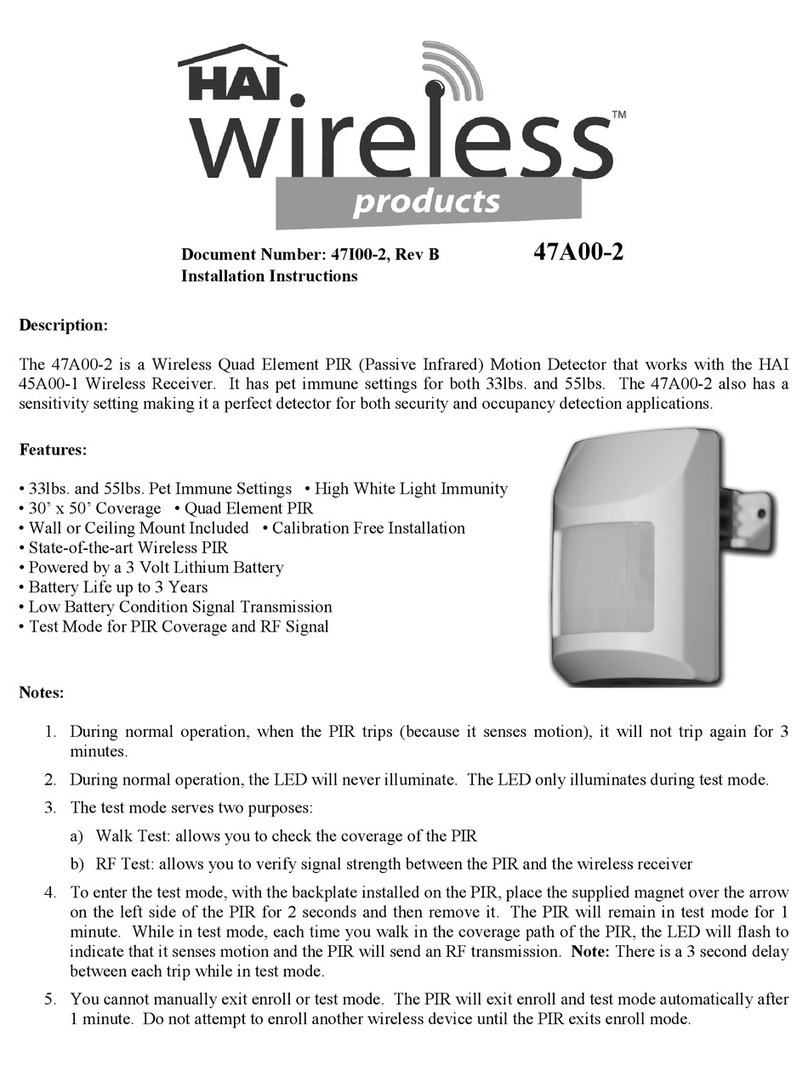

Flat light pipe

Coaster

Angled light pipe

4"x 4" Cosmetic adapter

Coaster