High Bay/Low Bay Passive Infrared Dimming Occupancy Sensor with Daylight Sensing and Offset Adaptor

Cat. Nos. HB011-PDX, HB011-PD2, HB011-BDX, HB011-BD2, HB0LA-PDX

Ratings: HB011-PDX, HB011-BDX, HB0LA-PDX: 120-230-277V, 50/60Hz

HB011-PD2, HB011-BD2: 347V, 60Hz

Load Ratings (one hot leg, same phase only):

800 W tungsten load @ 120 VAC - 1200 W tungsten load @ 277 VAC

8 A Electronic Ballast @ 120 VAC, 5 A Electronic Ballast @ 277 VAC, 1500 VA @ 347 VAC (Ballast only), Motor Load: 1/4 HP

Dimming Loads:

0-10VDC dimmable ballasts or LED drivers only, Sinks 20 mA maximum (~ 40 LED drivers/ballasts @ 0.5 per)

Minimum Load: 0.1mA

WARNINGS

• TO AVOID FIRE, SHOCK, OR DEATH: TURN OFF POWER at circuit breaker or fuse and test that the power is off before wiring.

• TO AVOID FIRE, SHOCK, DEATH, OR DAMAGE TO PROPERTY, DO NOT control a load in excess of the specified ratings. Check your load

ratings to determine the unit’s suitability for your application.

• Disconnect power when servicing luminaire or changing bulbs.

CAUTIONS

• To be installed and/or used in accordance with electrical codes and regulations.

• Use this device with COPPER OR COPPER CLAD WIRE ONLY.

• Do not attempt to disassemble or repair. Clean outer surface with a damp cloth only.

• If you are not sure about any part of these instructions, consult an electrician.

FEATURES

INSTALLATION

SETTINGS AND CALIBRATION

• Fixture or electrical box mounted Passive Infrared Occupancy Sensor

• Integrated Photocell

• Adjustable Time Delay

• Auto Calibration

• Pre-stripped color coded wire leads

21" length (HB011-PDX, PD2) - 42" length (HB011-BDX, BD2, HB0LA)

• Optional aisle mask

• 0-10V Dimming

• Partial OFF modes

• Adjustable PIR sensitivity

• Ladderless daylighting configuration

• Visual LED indications for easy troubleshooting

• 360° field-of-view for 20 ft. to 40 ft. High Bay mounting heights

• 360° field-of-view for 8 ft. to 20 ft. Low Bay mounting heights

• H.I.S. (High Inrush Stability) Technology

- Zero Crossing

- Robust Mechanical Latching Relays

• LED indicator light blinks when sensor detects motion, visible from long distance

• False Detection Filtering

• Rapid response to vehicles

• Offset Adapters (sold separately) positions sensor at optimum field-of-view

DESCRIPTION

Leviton’s High Bay Occupancy Sensors, Cat. No. HB011, are specifically designed

for high mounted areas such as warehouses, manufacturing and other high ceiling

applications. The HB011 installs directly to an industrial luminaire or an electrical junction

box. It is a self-contained sensor and relay that detects motion using the passive infrared

(PIR) to sense sources (such as a person entering a room) within its field-of-view

(monitored space) and automatically switches lights ON. The controlled lights will remain

ON until no motion is detected and the scheduled time-delay has expired. The daylight

sensor is sensitive to ambient light and has a threshold level that can be user-adjusted.

The HB011 is supplied with two interchangeable lens rings that allows the user to select

between a 360 degree High Bay or Low Bay pattern and an aisle pattern with the included

aisle mask.

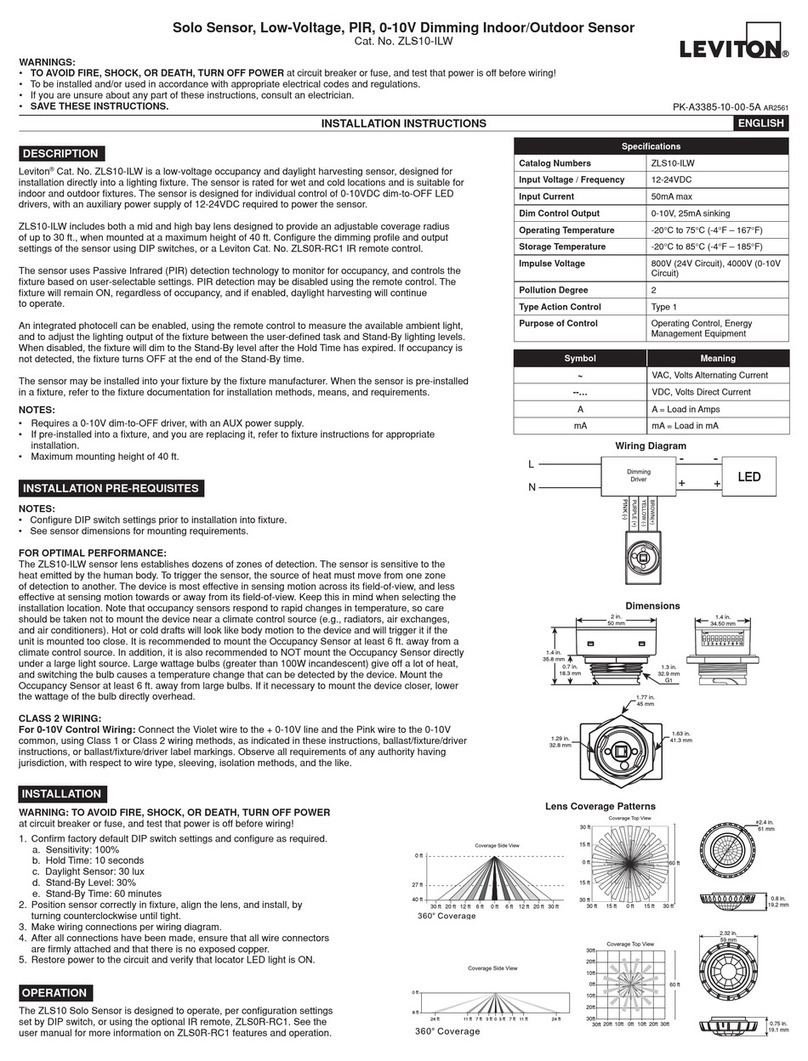

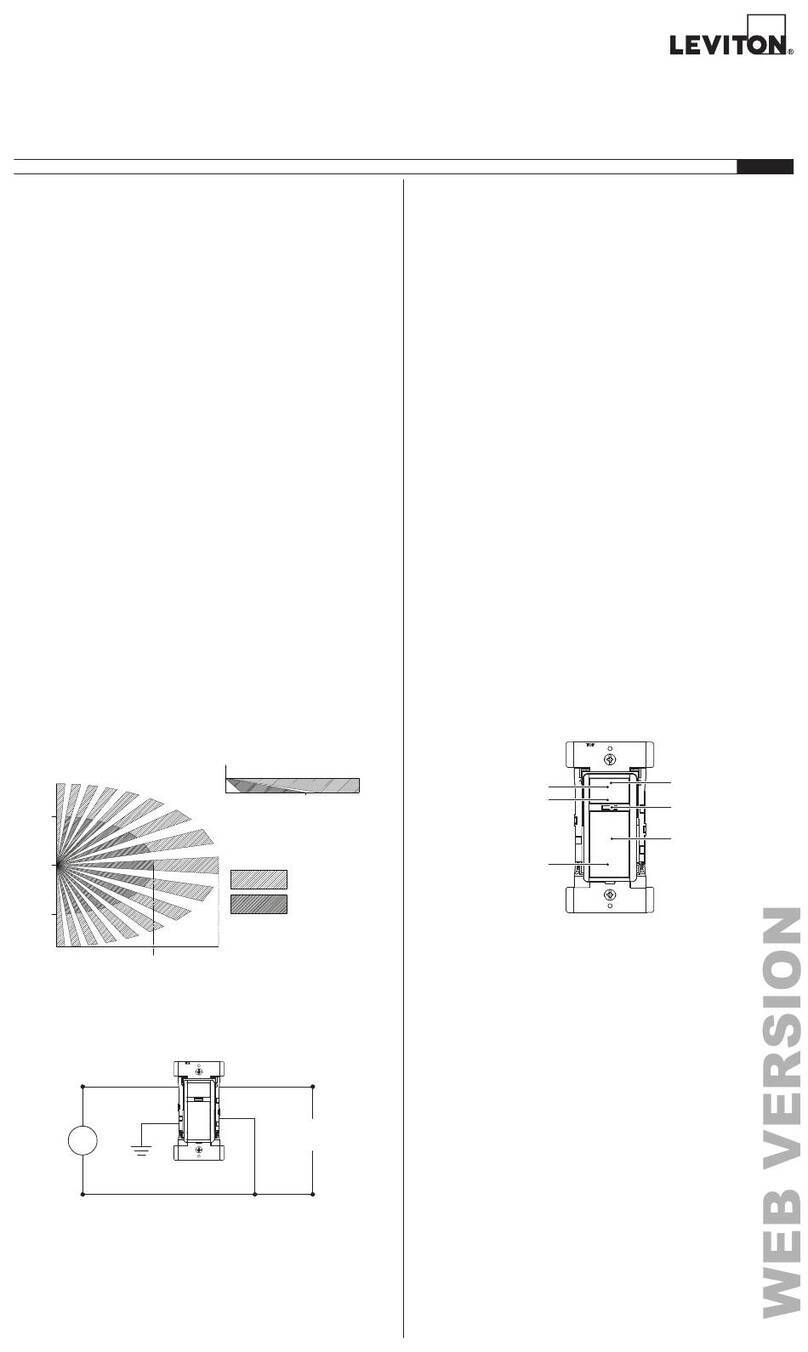

The Sensor’s High Bay lens and aisle lens is designed for 20 ft. to 40 ft. mounting heights

for a symmetrical pattern which will provide coverage of 50’ to 60’ diameter (refer to

Figure 4 and 5). The Low Bay lens is designed for 8 ft. to 20 ft. mounting heights for a

symmetrical pattern which will provide coverage of 30’ to 50’ diameter (refer to Figure 6).

The Sensor is sensitive to the heat emitted by the human body.

In order to initially trigger the Sensor, the source of heat must move from one zone

of detection to another.

Note that occupancy sensors respond to rapid changes in temperature, so care should be

taken not to mount the device near a climate control source (i.e. radiators, air exchanges,

and air conditioners). Hot or cold drafts will look like body motion to the device and will

trigger it if the unit is mounted too close.

Mount the Occupancy Sensor 6 ft. away from the heating or cooling ventilation

source.

NOTE: The HB011 is supplied with two lens trim rings. The 360 degree High Bay

lens (white color trim ring) and the 360 degree Low Bay lens (blue color trim ring)

in the carton. An aisle mask is included for aisle coverage if desired. Change the lens for

use in aisle or Low Bay applications. See below for changing lens trim ring. The HB011

Photocell Auto Calibration

- To enable photocell or start Auto Calibration, turn the PHOTO SETPOINT knob

from OFF position to any DDL setpoint (this can be done when power is removed).

The LED will be solid GREEN and Lights will be forced ON for 24 hours indicating

the device has entered Auto Calibration Mode.

HB011 WIRE TABLE

Color Description

Black Line

White Neutral

Red Load 1

Violet 0-10V + Dim Out

Pink 0-10V - Common

FACTORY SETTINGS

Configuration Value

Time Delay 10 minutes

PIR Sensitivity 75% of maximum

Photocell Setpoint OFF

Mode DOFF T2 = 0

Installed Lens White - High Bay

SENSITIVITY

MAX MIN

30

MIN

20

10

30

SEC

5

MIN

DMIN

T2 = ∞DOFF

T2 = 0

DMIN

T2 = 0

DMIN

T2 = 60

DOFF

T2 = 60

2.0X

1.5X

1.0X

OFF

0.5X

TIME DELAY PHOTO SETPOINT MODE

INTERIOR LIGHT LEVEL

ENERGY

SAVINGS

TIME OF DAY

12AM6AM12PM6PM12AM

TARGET

LIGHT LEVEL

ELECTRIC

LIGHTING

DAYLIGHT ENERGY

SAVINGS

LED INDICATORS

RED Blink PIR Detection

Solid Device Failure

GREEN Blink 24 hr Auto Calibration

BLUE Blink 1x/30s PC Hold OFF Mode

Blink Dial Setting Change

YELLOW Solid 15s Power Time

Blink Photocell Test Mode

PK-A3145-10-00-2D

NOTE: Allow approximately 30 seconds for charge-up. If the lights turn ON and the LED

blinks when a hand is waved in front of the lens, then the Sensor was installed properly. If

the operation is different, refer to the TROUBLESHOOTING SECTION.

The Sensor is factory preset to work without any adjustments. If you desire to change the

factory settings, refer to the SETTINGS AND CALIBRATION section.

INSTALLATION INSTRUCTIONS ENGLISH

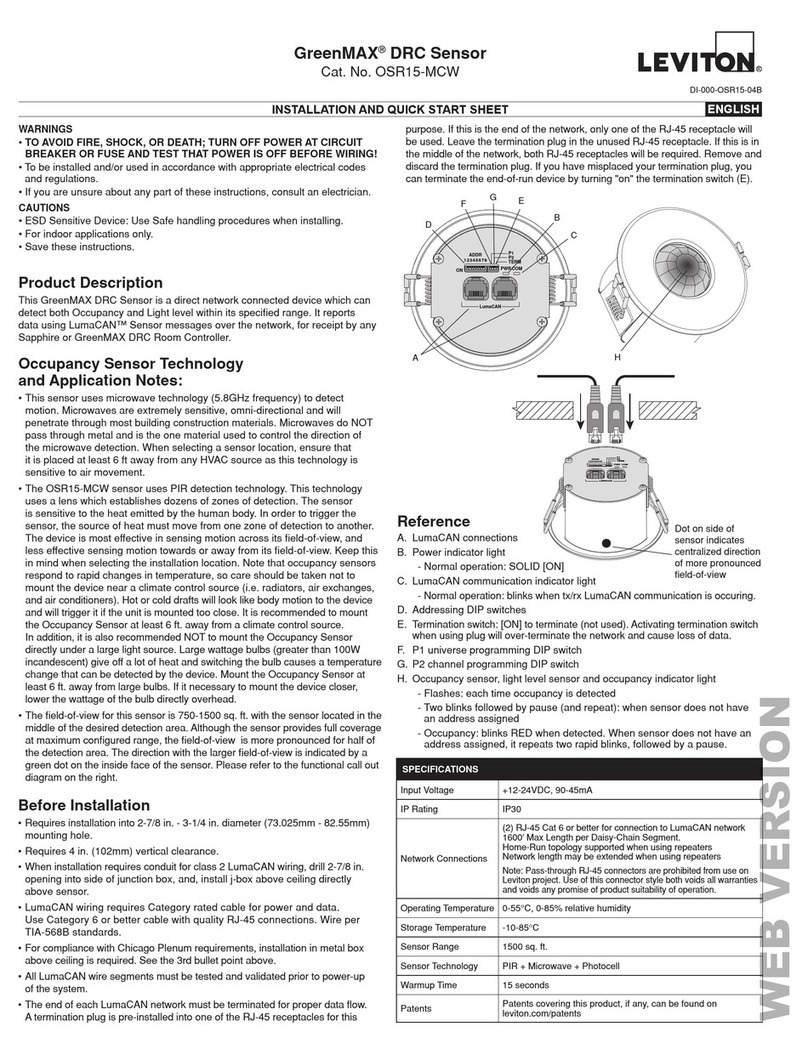

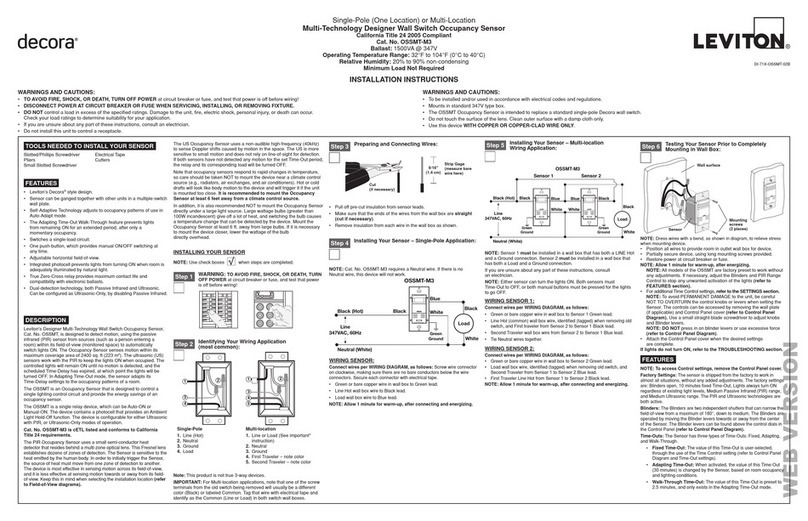

Hot (Black)

Neutral (White) Neutral (White)

Red (Load)

White

Sensor

Black

Ballast/

Driver

Pink

Violet

Line

120-230-277VAC

50/60 Hz

or

347VAC

60 Hz

(-)

(+)

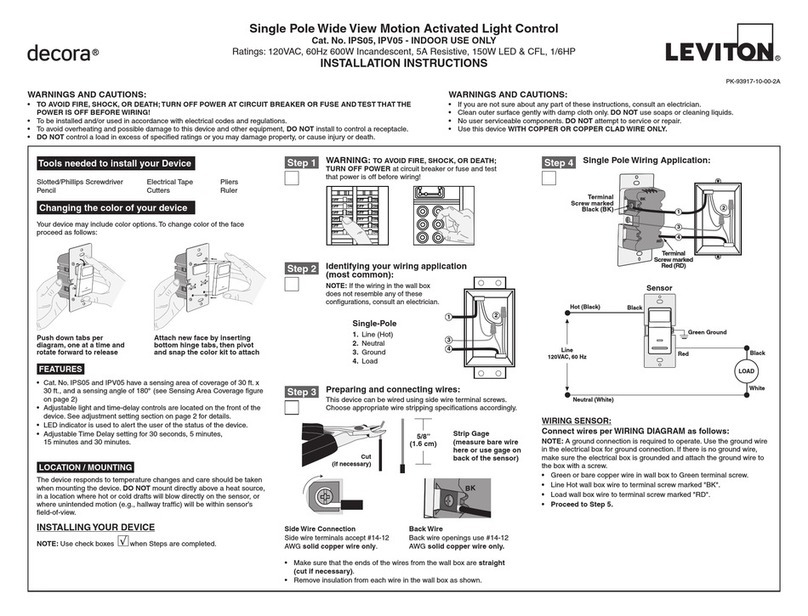

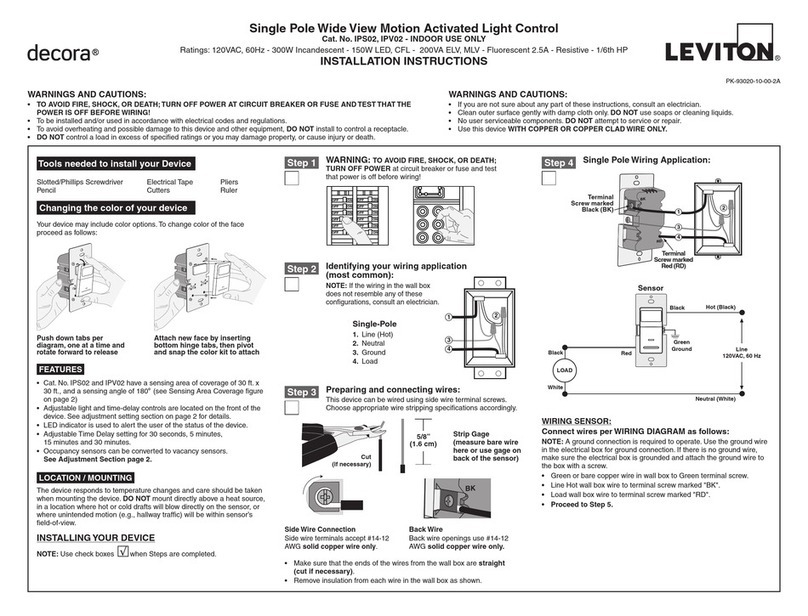

Sensor mounts in a 1/2” knock out hole on the end of a luminaire or an electrical box.

The Sensor’s field-of-view may be partially obstructed by the luminaire housing (refer to

Figure 1A). At higher mounting heights, the outer beams are not used. As long as the

bottom of the sensor is mounted within 1” from the bottom of the luminaire, the field-of-

view will not be affected (refer to Figure 1B).

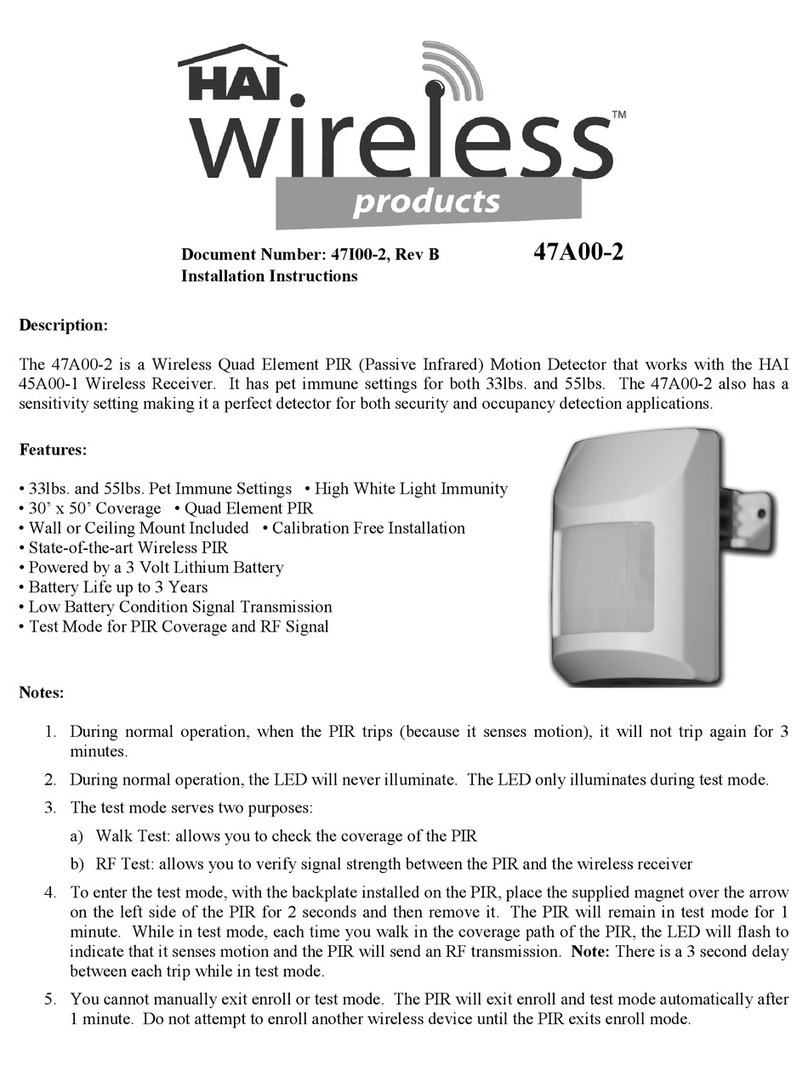

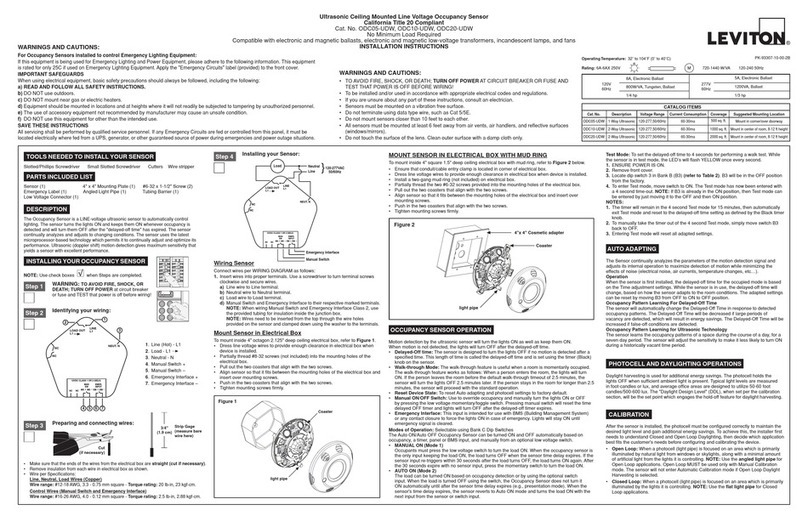

ADAPTER NOTE: For deep bodied luminaires or to clear other obstructions use Leviton’s

OSFOA-00W Adapter. The Adapter is designed to provide multiple mounting positions

to accommodate different mounting heights for optimum sensor positioning. A keyed,

threaded snap-in nipple that holds the Adapter in place while tightening the provided

lock-nut. The OSFLO is a single height position adapter with a quick install snap in fitting

without a lock nut (refer to Figures 2A and 2B).

NOTE: Catalog number HB0LA-PDX is an assembly of the OSFLO Adaptor and an

HB011-PDX.

1. To change lens, turn trim ring so that the two indented dots line up and pull out by the

finger tabs (refer to Figure 7A).

2. Remove the inner lock-nut from the threaded nipple and insert the wires and the

threaded nipple into a half inch hole of the luminaire body or the electrical box.

NOTE: Mounting nipple has a “snap” feature for quick installation into round or

“double-D” holes, as well as a “keying” mechanism to prevent rotation after installation

in “double-D” holes.

3. Slide the lock-nut over the wires and thread clockwise onto the threaded nipple to

secure the sensor firmly in place making sure the lens is orientated towards the area to

be monitored (field-of-view) (refer to Figure 3).

4. Connect wires per Wiring Diagram as follows: RED leads to LOAD; WHITE leads to

NEUTRAL; BLACK leads to LINE (Hot). Connect 0-10V dimming wires (Pink & Violet).

Twist strands of each lead tightly and, with circuit conductors, push firmly into the

appropriate wire connector. Screw connector on clockwise making sure that no bare

wire shows below the connector.

5. Restore power at circuit breaker or fuse.

- When Auto Calibration is complete, the LED will resume normal operation.

The device is now daylighting.

- To reset to factory default, power ON the device and turn the PHOTO SETPOINT

knob to OFF position for 5 seconds.

NOTE:

- A significant change in light source like relamping requires re-calibration by

resetting to factory default.

- If the calibration process does not successfully complete due to power outage,

it will restart at the next power-up if the knob is not in the OFF position.

- To disable photocell or cancel Auto Calibration turn the PHOTO SETPOINT knob

to OFF position.

- The DDL can be adjusted by turning the PHOTO SETPOINT knob.

Figure 1A

Sensor mounted too high

Outer beams are obstructed

Field-of-view is limited

INCORRECT

Figure 1B

Sensor mounted within 1" of bottom

No obstruction

Optimum field-of-view

CORRECT

NOTE: Depending on date of manufacture, the pink 0-10V wire may be gray

NOTE: Depending on date of manufacture, the pink 0-10V wire may be gray