Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes LGE Internal Use Only

- 4 -

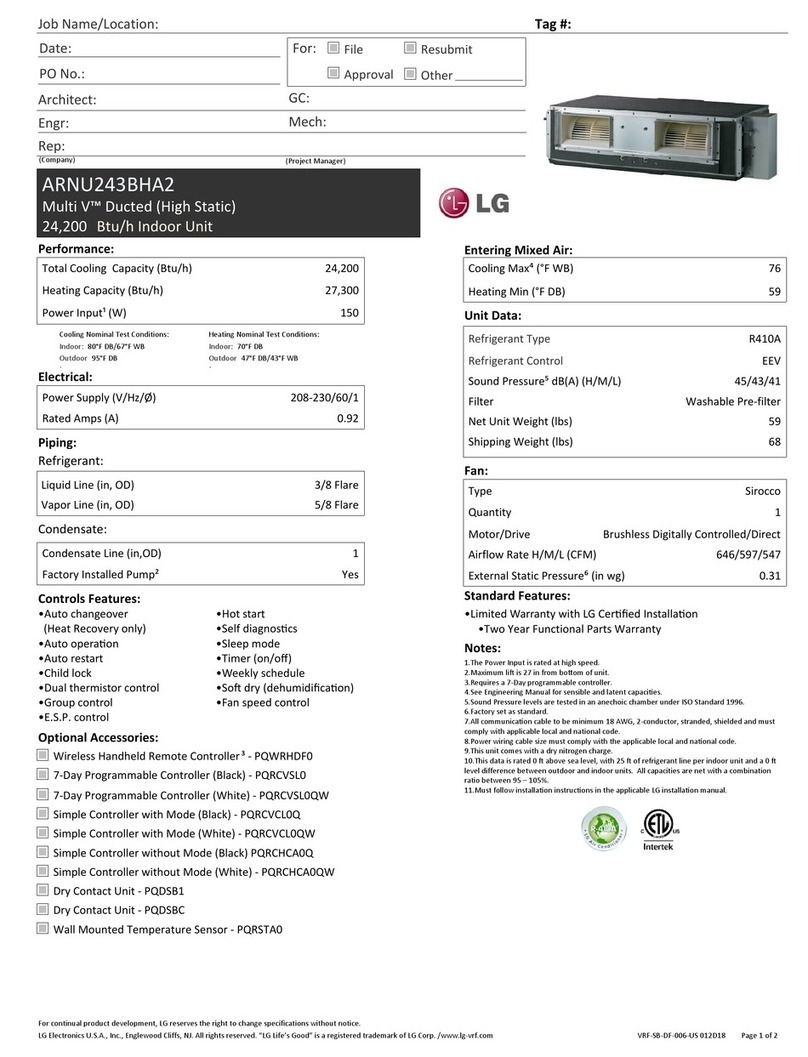

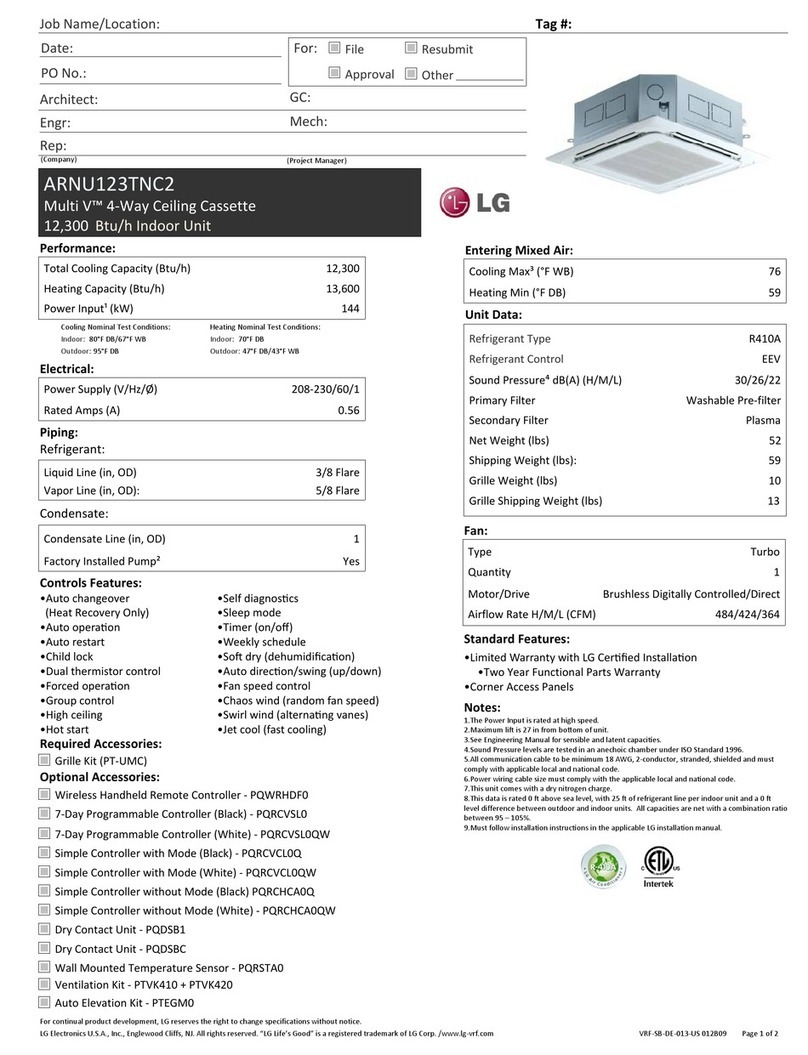

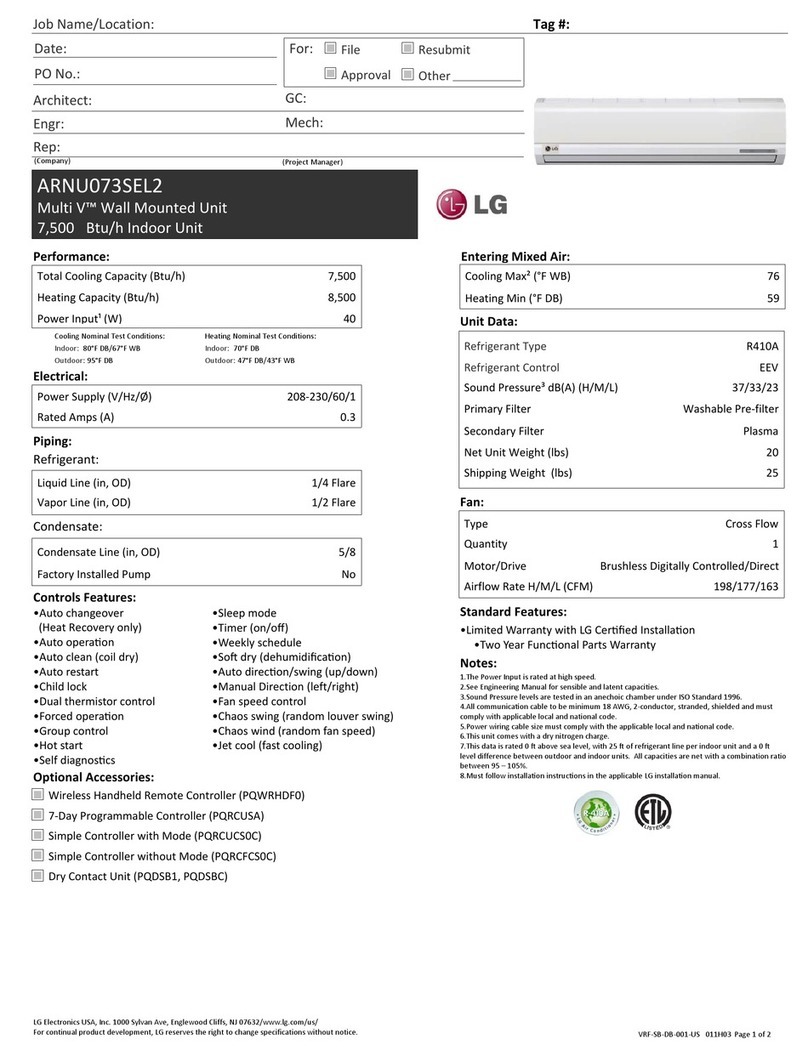

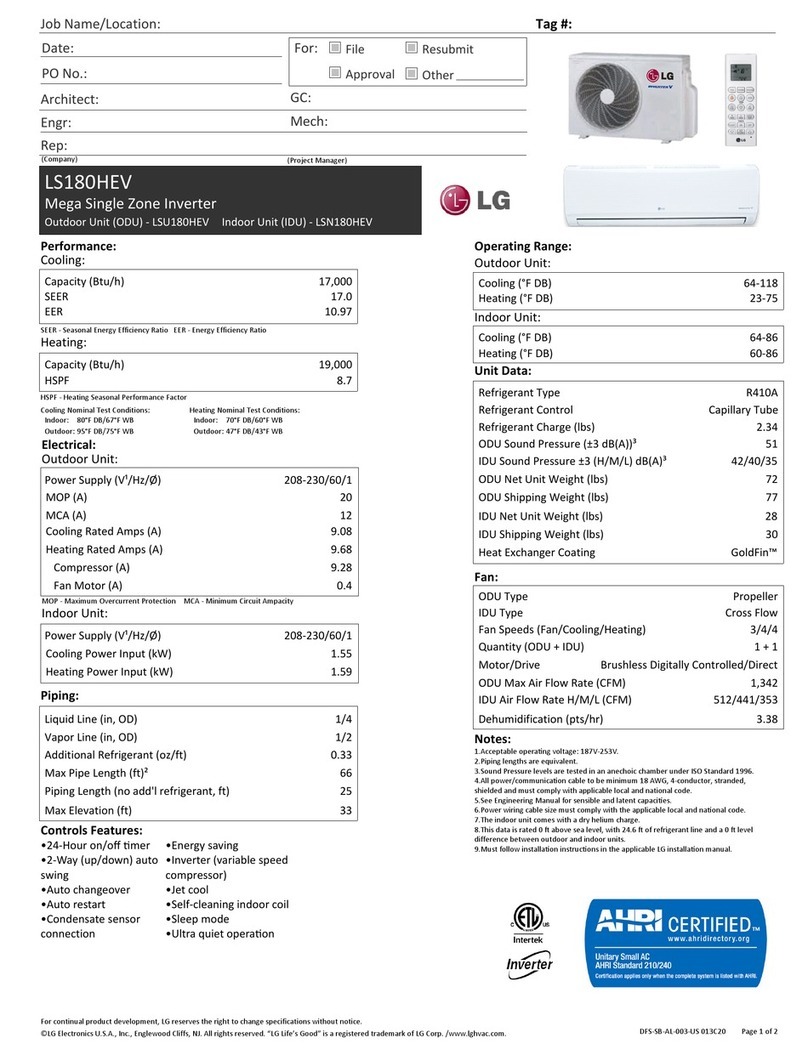

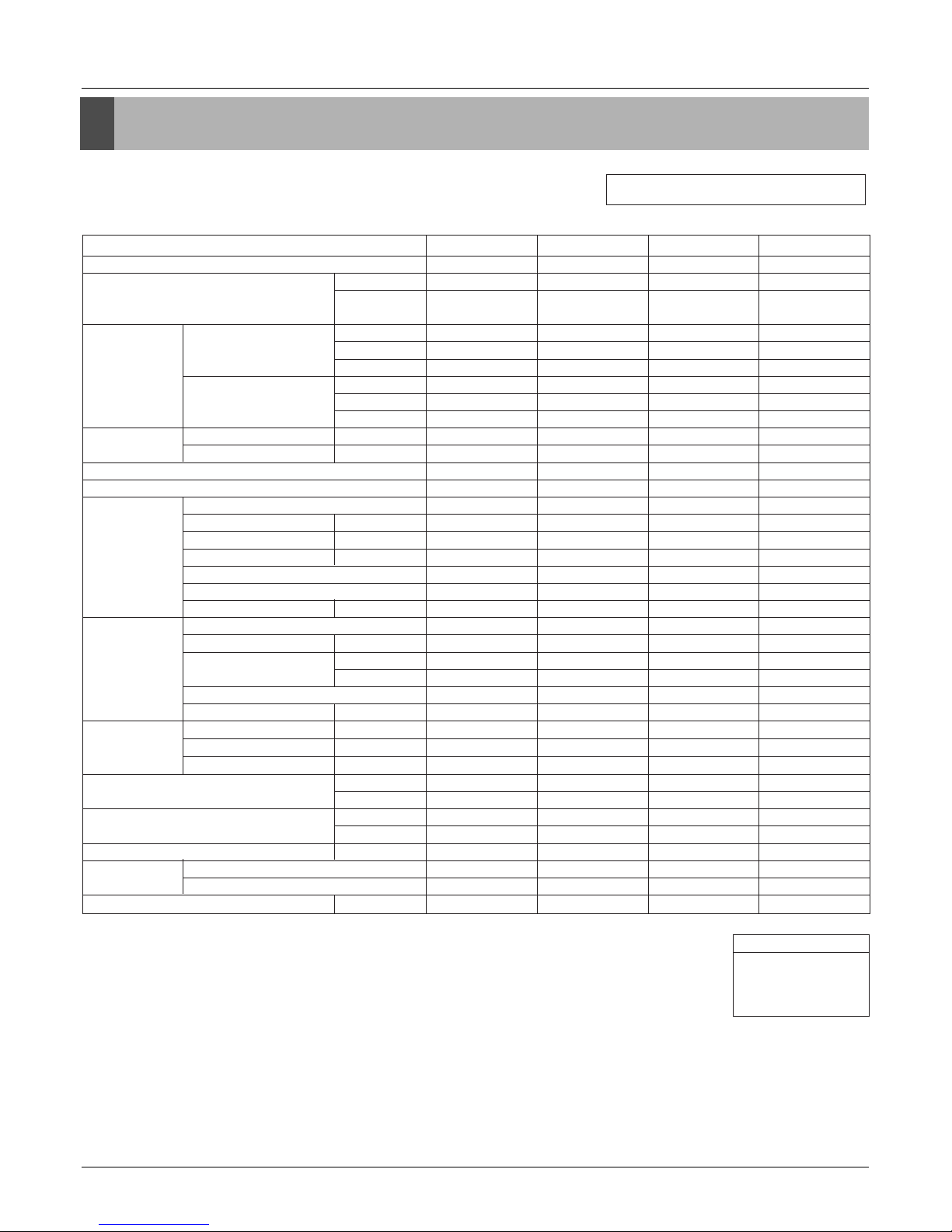

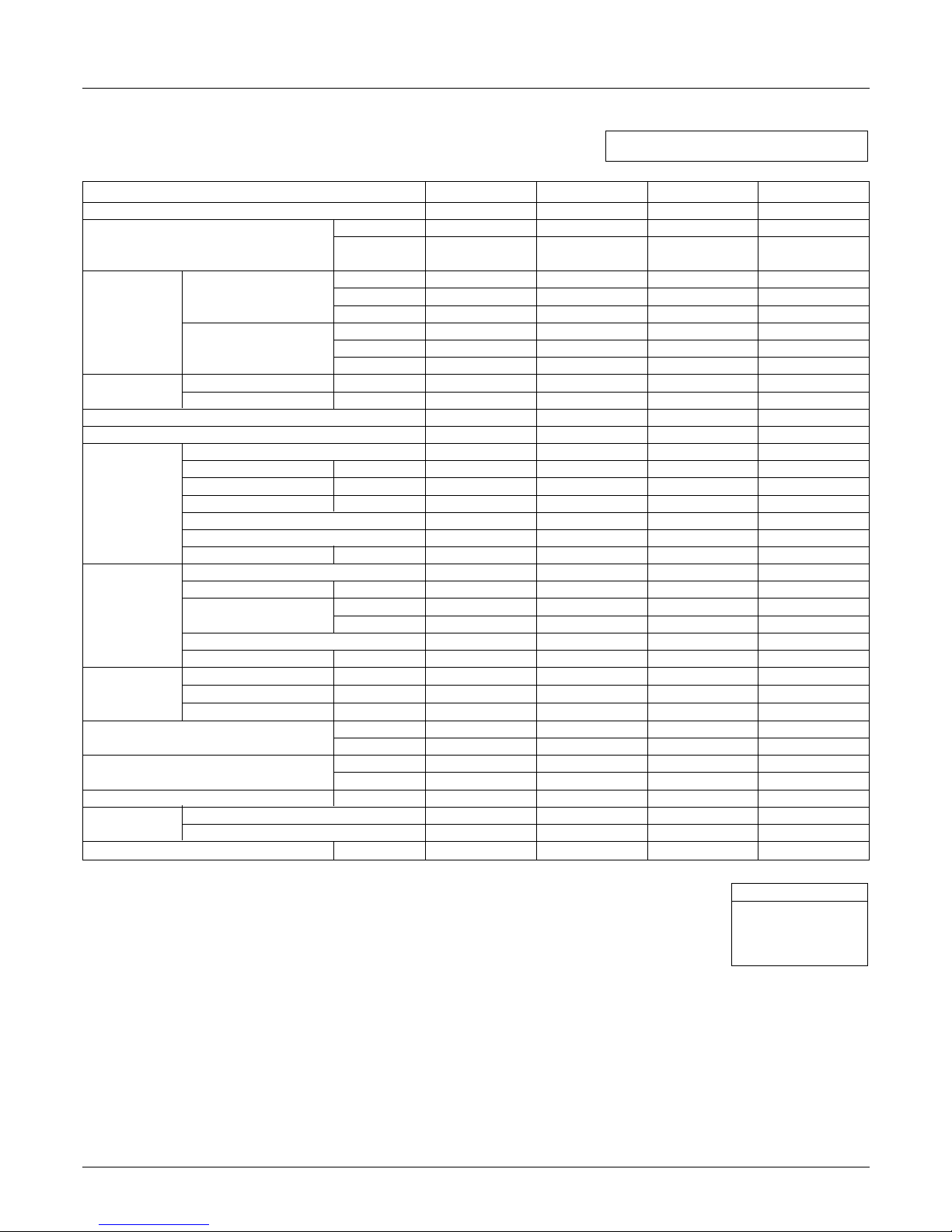

Specification

HP(Equivalent horsepower)

Ton

Model Name Combination Unit

Independent Unit

Capacity Cooling kW

kcal/h

Btu/h

Heating kW

kcal/h

Btu/h

Input Cooling kW

Heating kW

Casing Color

Heat Exchanger

Compressor Type

Piston Displacement cm3/rev

Number of Revolution R.P.M

Motor Output x Number

W

Starting Method

Oil Type

Oil Charge cc

Fan Type

Motor Output x Number W

Air Flow Rate(High) CMM

cfm

Drive

Discharge Side / Top

Pipe Connctions Liquid(flare) mm(inch)

Suction Gas mm(inch)

Discharge Gas mm(inch)

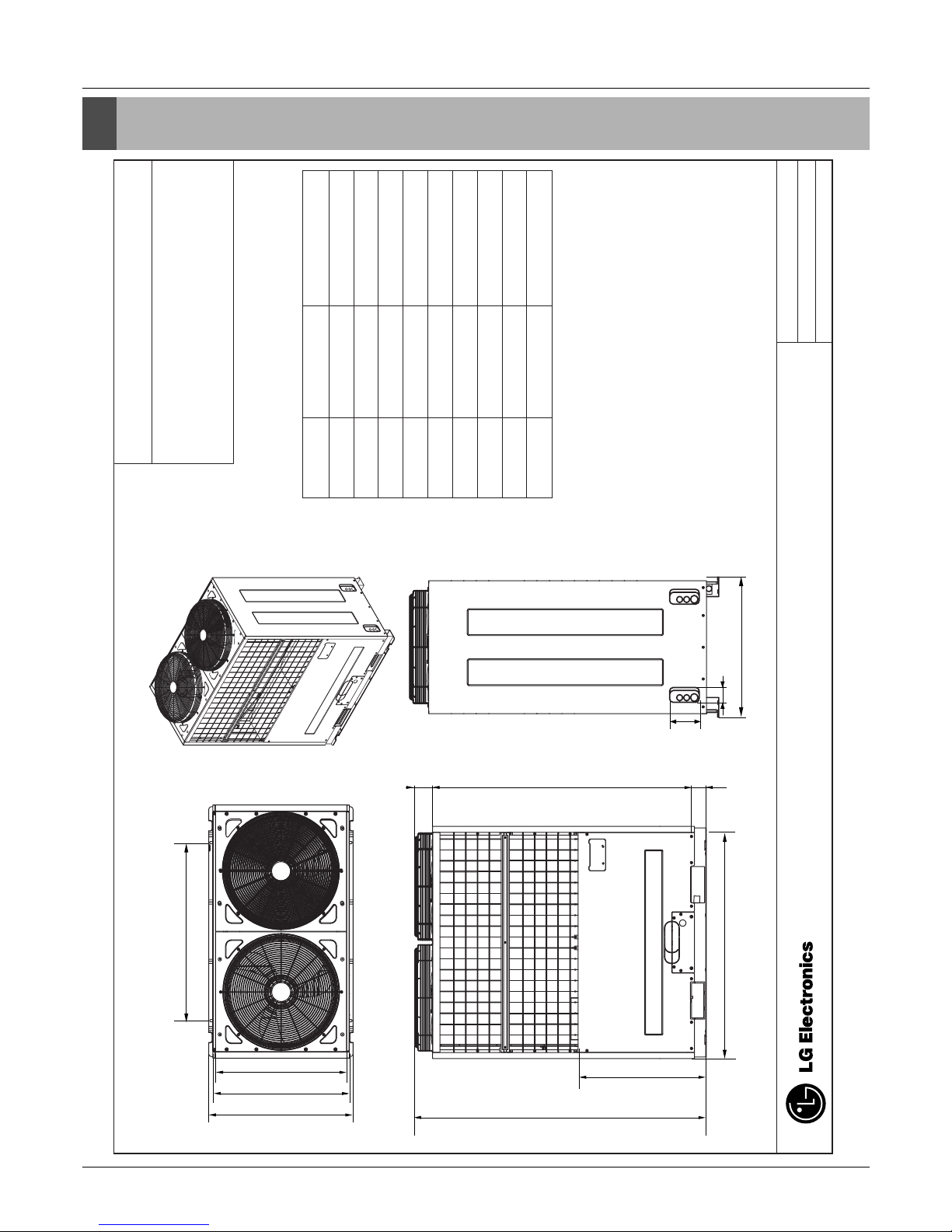

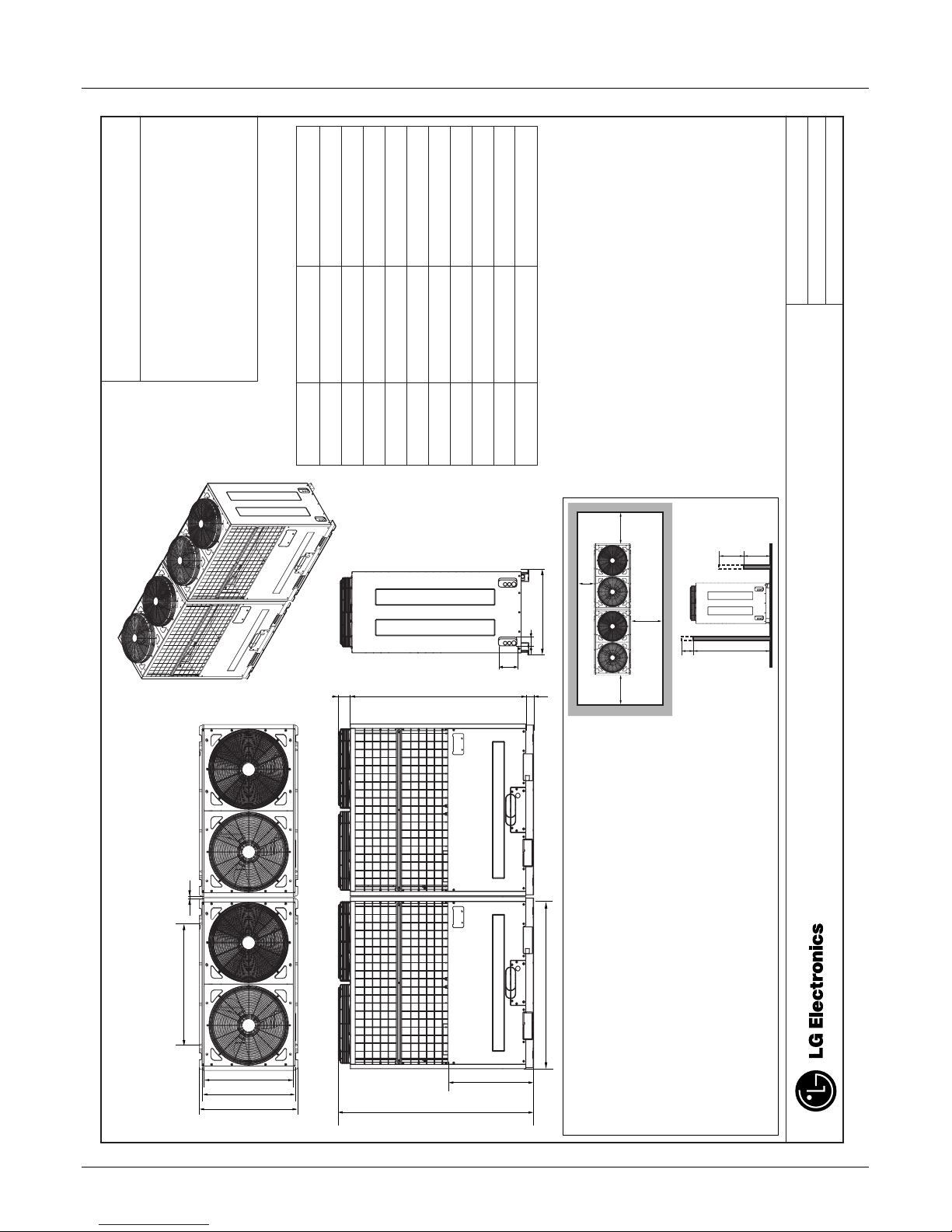

Dimensions (WxHxD) mm

inch

Net Weight kg

lbs

Communication Cable mm2

Refigerant Refigerant name

Control

Power Supply Ø, V, Hz

18 20 22 24

14.5 16.0 17.5 19.0

ARUB173BT2 ARUB192BT2 ARUB211BT2 ARUB230BT2

ARUB096BT2 ARUB096BT2 ARUB115BT2 ARUB115BT2

ARUB076BT2 ARUB096BT2 ARUB096BT2 ARUB115BT2

50.4 56.0 61.6 67.2

43,300 48,200 53,000 57,800

172,000 191,100 210,200 229,300

56.7 63.0 69.3 75.6

48,800 54,200 59,600 65,000

193,500 225,000 236,500 258,000

14.00 15.60 18.60 21.60

15.80 17.60 19.90 22.20

Warm Gray Warm Gray Warm Gray Warm Gray

Gold fin Gold fin Gold fin Gold fin

DC Scroll DC Scroll DC Scroll DC Scroll

(38.3 + 59.8)x2 (38.3 + 59.8)x2 (38.3 + 59.8)x2 (38.3 + 59.8)x2

(3,600+3,500)x2 (3,600+3,500)x2 (3,600+3,500)x2 (3,600+3,500)x2

(4,130 + 5,280)x2 (4,130 + 5,280)x2 (4,130 + 5,280)x2 (4,130 + 5,280)x2

Direct On Line Direct On Line Direct On Line Direct On Line

FVC68D(PVE) FVC68D(PVE) FVC68D(PVE) FVC68D(PVE)

5,600x2 5,600x2 5,600x2 5,600x2

Propeller fan Propeller fan Propeller fan Propeller fan

350 x 4 350 x 4 350 x 4 350 x 4

380 380 380 380

13,400 13,400 13,400 13,400

DC INVERTER DC INVERTER DC INVERTER DC INVERTER

TOP TOP TOP TOP

15.88(5/8) 15.88(5/8) 15.88(5/8) 15.88(5/8)

28.58(1 1/8) 28.58(1 1/8) 34.9(1 3/8) 34.9(1 3/8)

22.2(7/8) 22.2(7/8) 28.58(1 1/8) 28.58(1 1/8)

(1,280x1,607x730)x2 (1,280x1,607x730)x2 (1,280x1,607x730)x2 (1,280x1,607x730)x2

(50-3/8 x 63-5/16 x 28-11/16)x2 (50-3/8 x 63-5/16 x 28-11/16)x2 (50-3/8 x 63-5/16 x 28-11/16)x2 (50-3/8 x 63-5/16 x 28-11/16)x2

285+285 285+285 285+285 285+285

628+628 628+628 628+628 628+628

CVV-SB 1.25x2C CVV-SB 1.25x2C CVV-SB 1.25x2C CVV-SB 1.25x2C

R410A R410A R410A R410A

EEV EEV EEV EEV

3, 208/230, 60 3, 208/230, 60 3, 208/230, 60 3, 208/230, 60

Notes:

1. Capacities are based on the following conditions:

Cooling * Indoor temp. 27°C[80.6°F]DB/ 19°C[66.2°F]WB

* Outdoor temp. 35°C[95°F]DB/ 24°C[75.2°F]WB

* Interconnecting Piping Length 7.5m(25ft)

* Level Difference of Zero

Heating * Indoor temp. 20°C[68°F]DB/ 15°C[59°F]WB

* Outdoor temp. 7°C[44.6°F]DB/ 6°C[42.8°F]WB

* Interconnecting Piping Length 7.5m(25ft)

* Level Difference of Zero

2. Capacities are net capacities

3. Due to our policy of innovation some specifications may be changed without prior notification

4. EEV : Electronic Expansion Valve

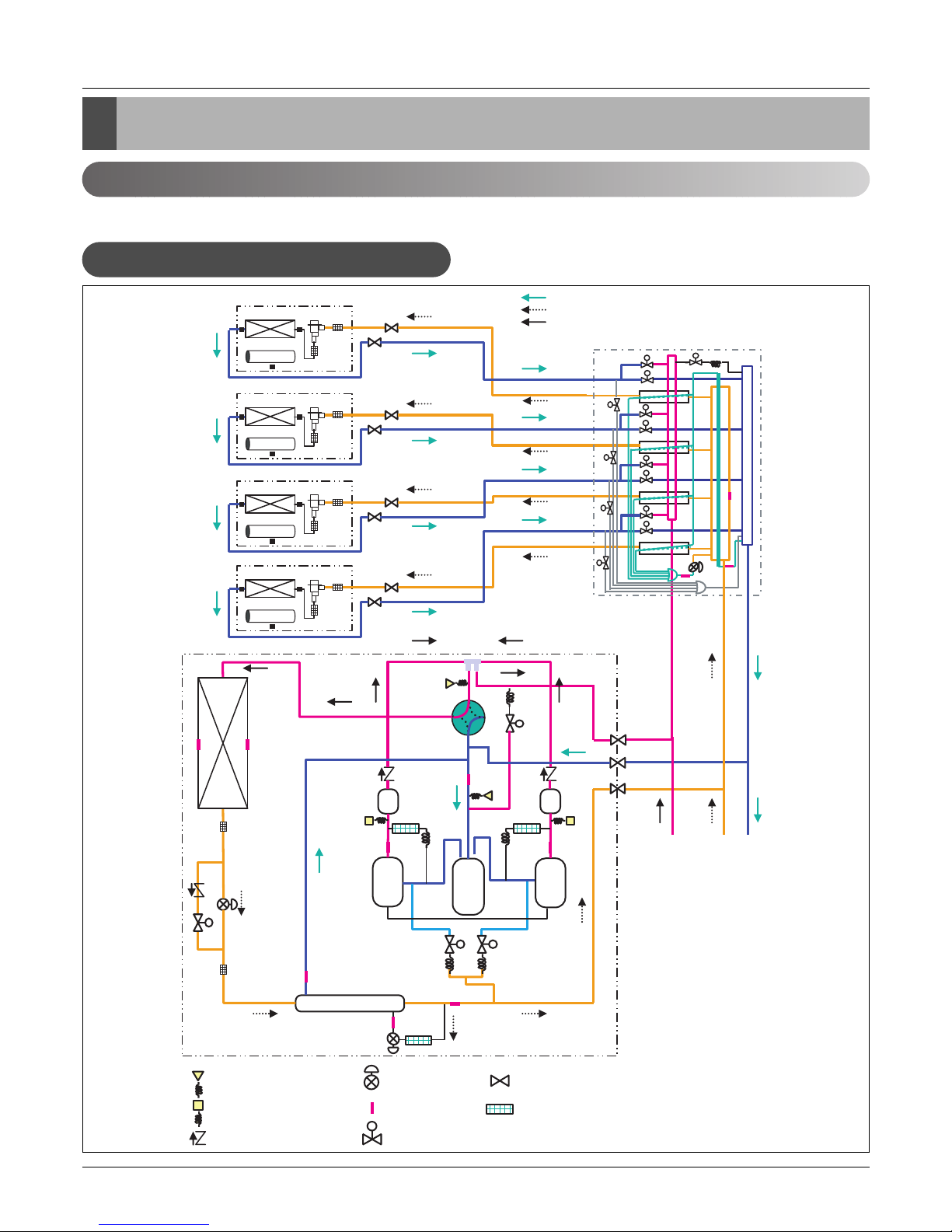

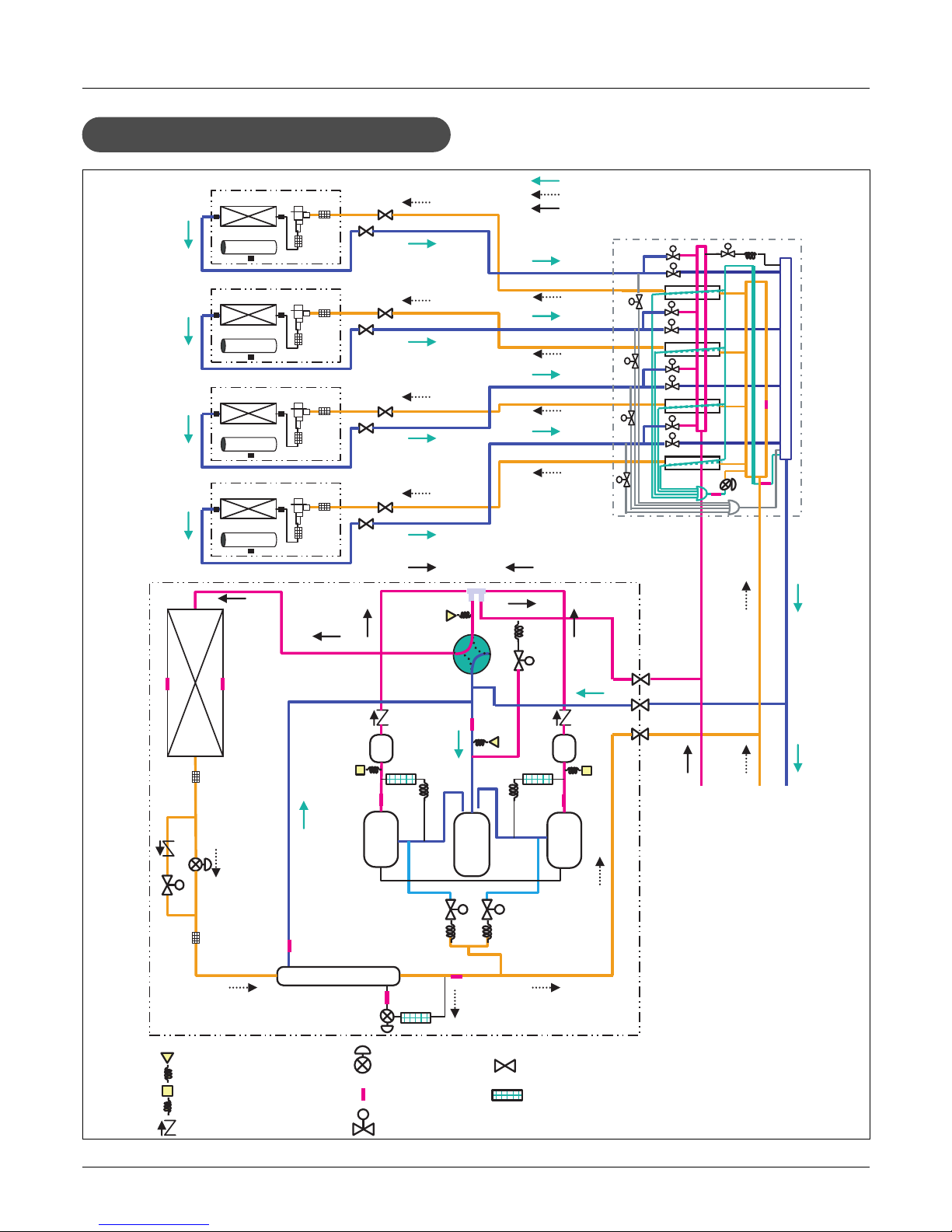

Heat Recovery(208/230V, 60Hz)

Conversion Formula

kcal/h= kW x 860

Btu/h = kW x 3412

cfm = m3/min x 35.3

l/s = CMM x 1000/60