Installation Manual 7

ENGLISH

Installation of Indoor, Outdoor Unit

Installation of Indoor, Outdoor Unit

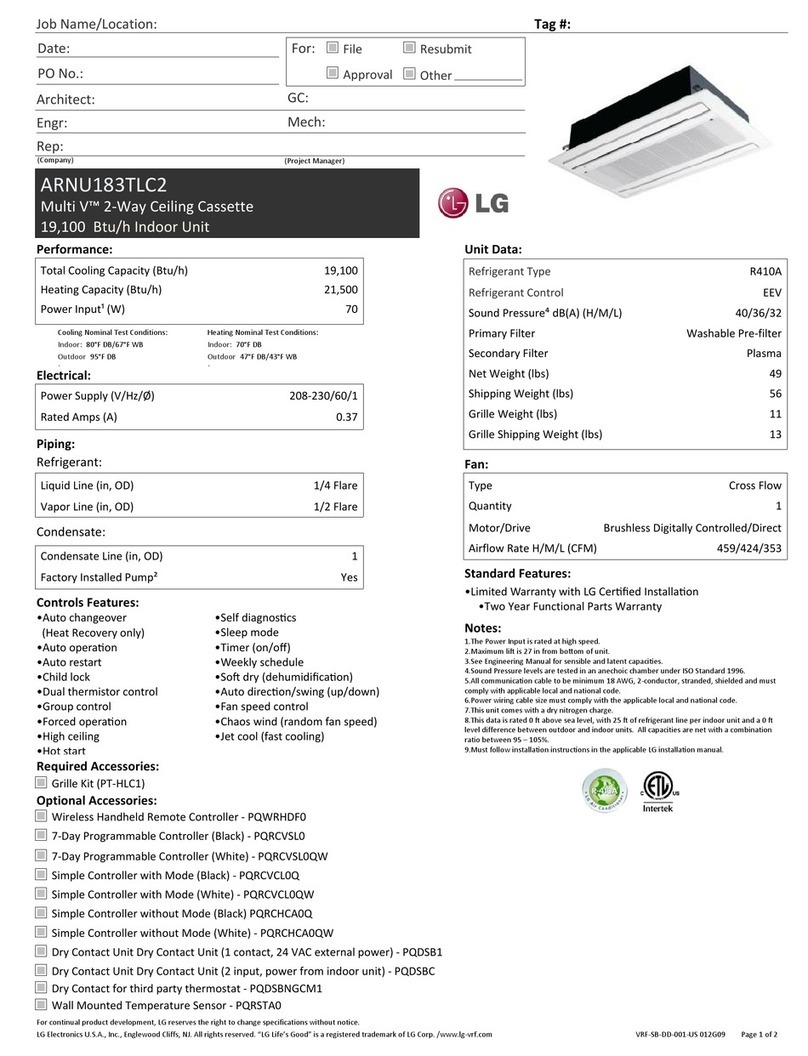

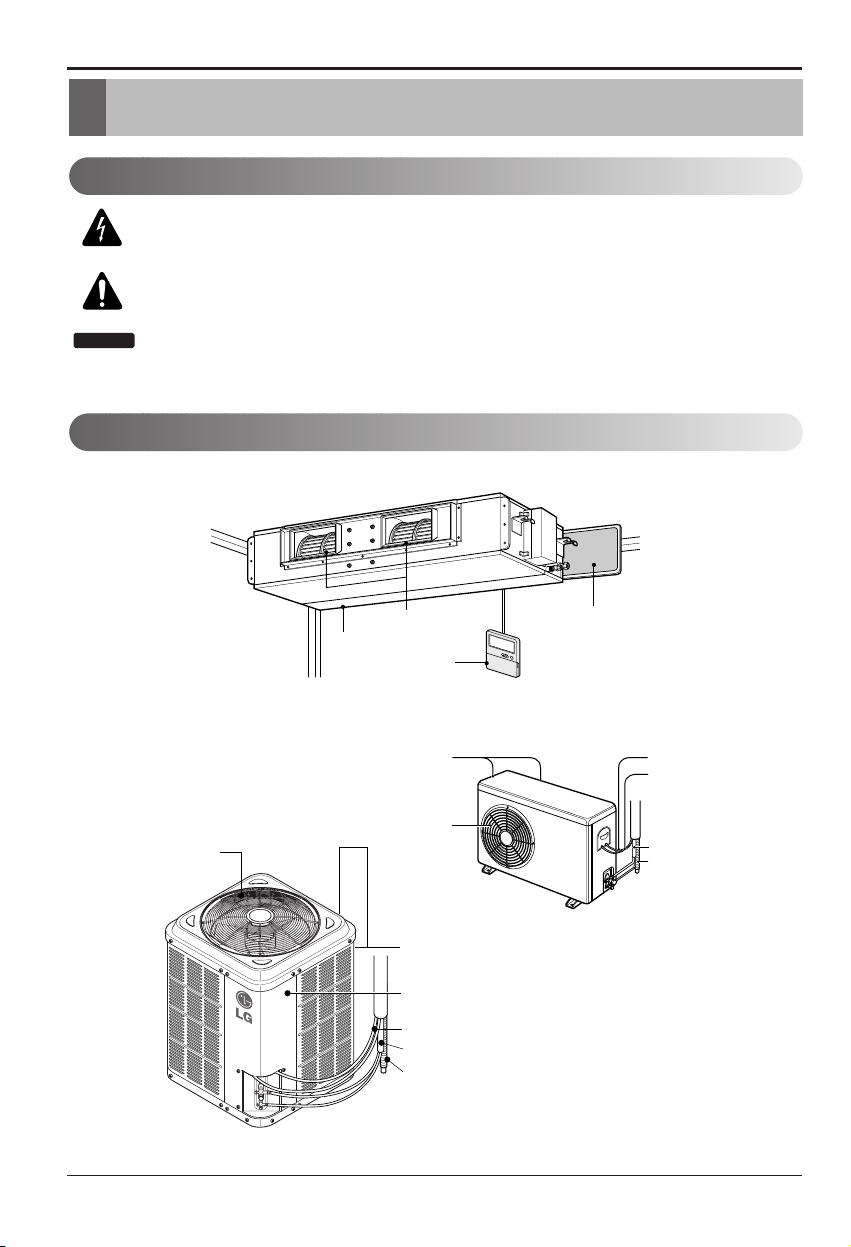

Indoor unit

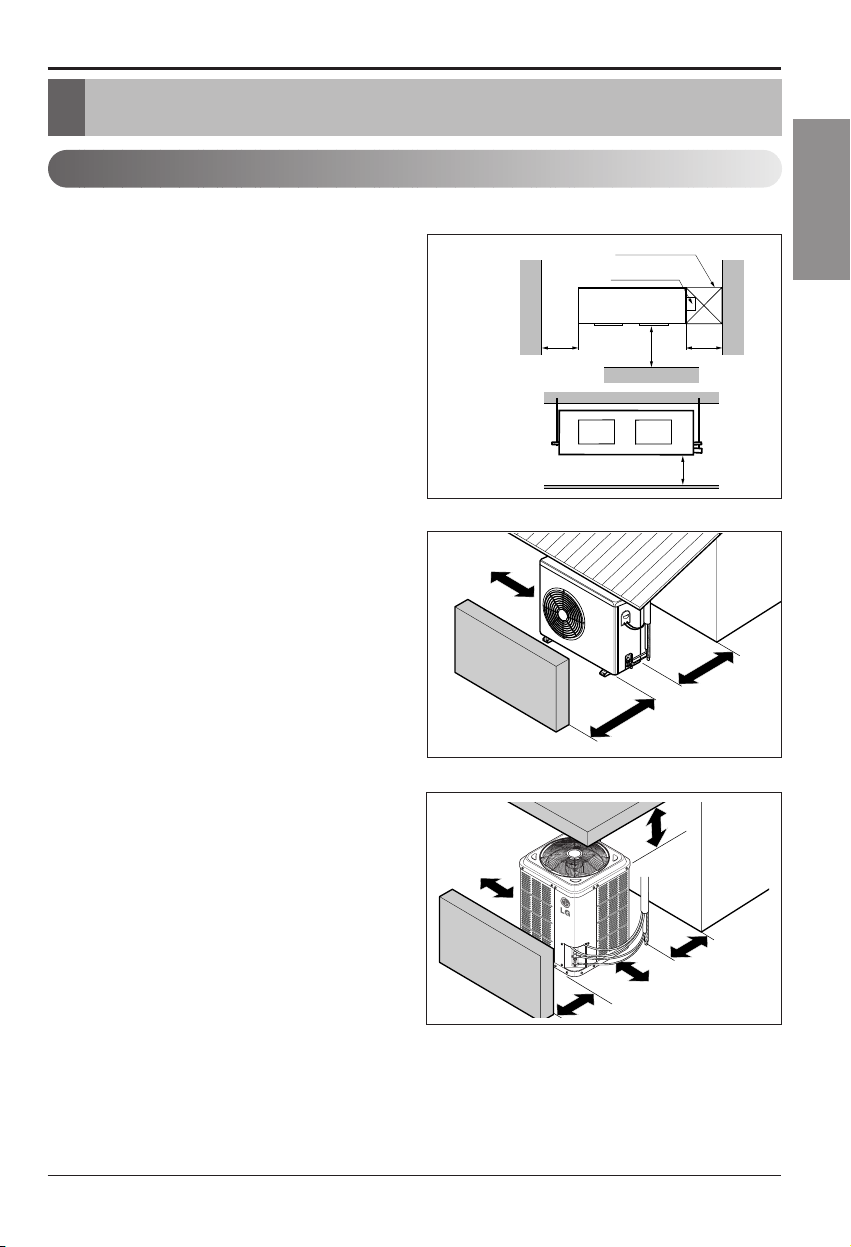

Install the air conditioner in the location that

satisfies the following conditions.

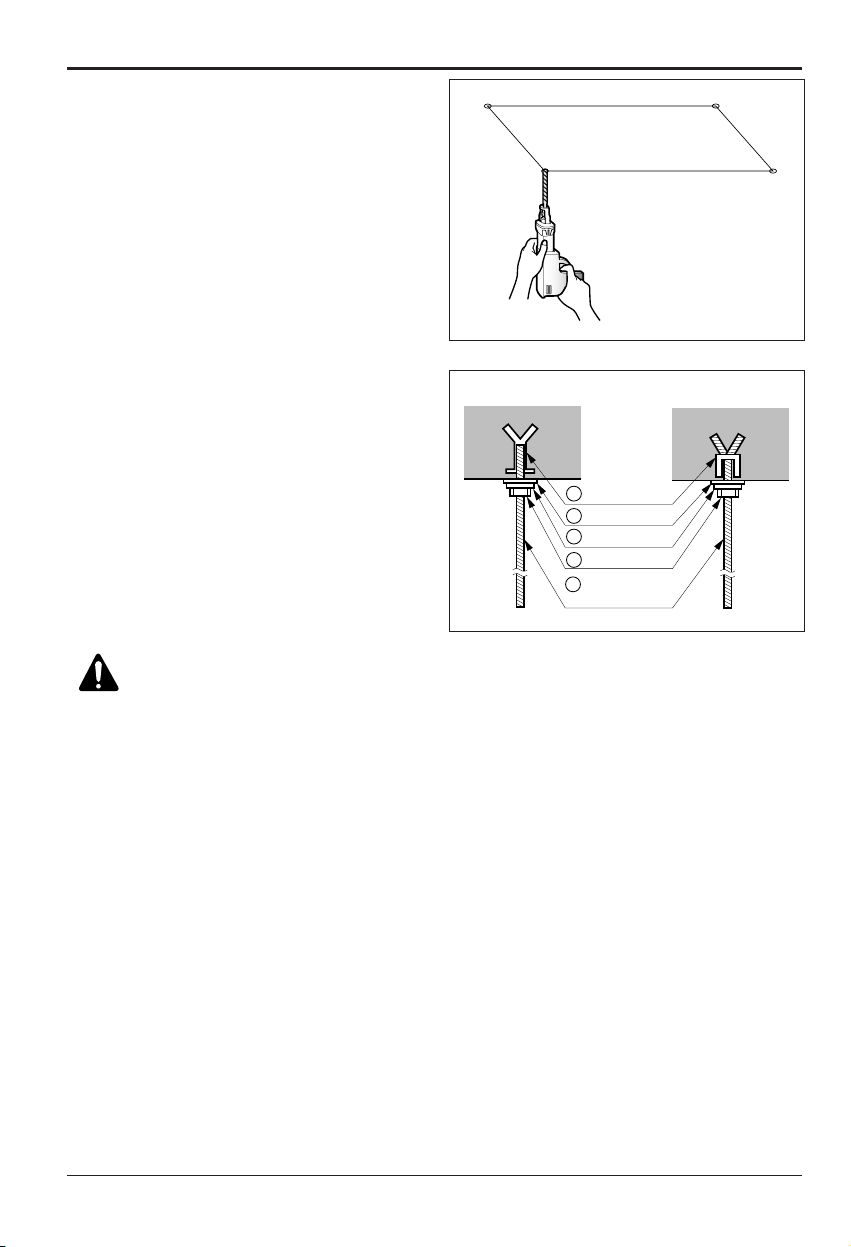

•The place shall easily bear a load exceeding

four times the indoor unit’s weight.

•The place shall be able to inspect the unit as

the figure.

•The place where the unit shall be leveled.

•The place shall allow easy water

drainage.(Suitable dimension “H”is necessary

to get a slope to drain as figure.)

•The place shall easily connect with the

outdoor unit.

•The place where the unit is not affected by an

electrical noise.

•The place where air circulation in the room will

be good .

•There should not be any heat source or steam

near the unit

Outdoor unit

•If an awning is built over the unit to prevent

direct sunlight or rain exposure, be careful that

heat radiation from the condenser is not

restricted.

•There should not be any animals or plants

which could be affected by hot air discharged.

•Ensure the spaces indicated by arrows from

the wall, ceiling, fence or other obstacles.

Selection of the best location