7

INDEX

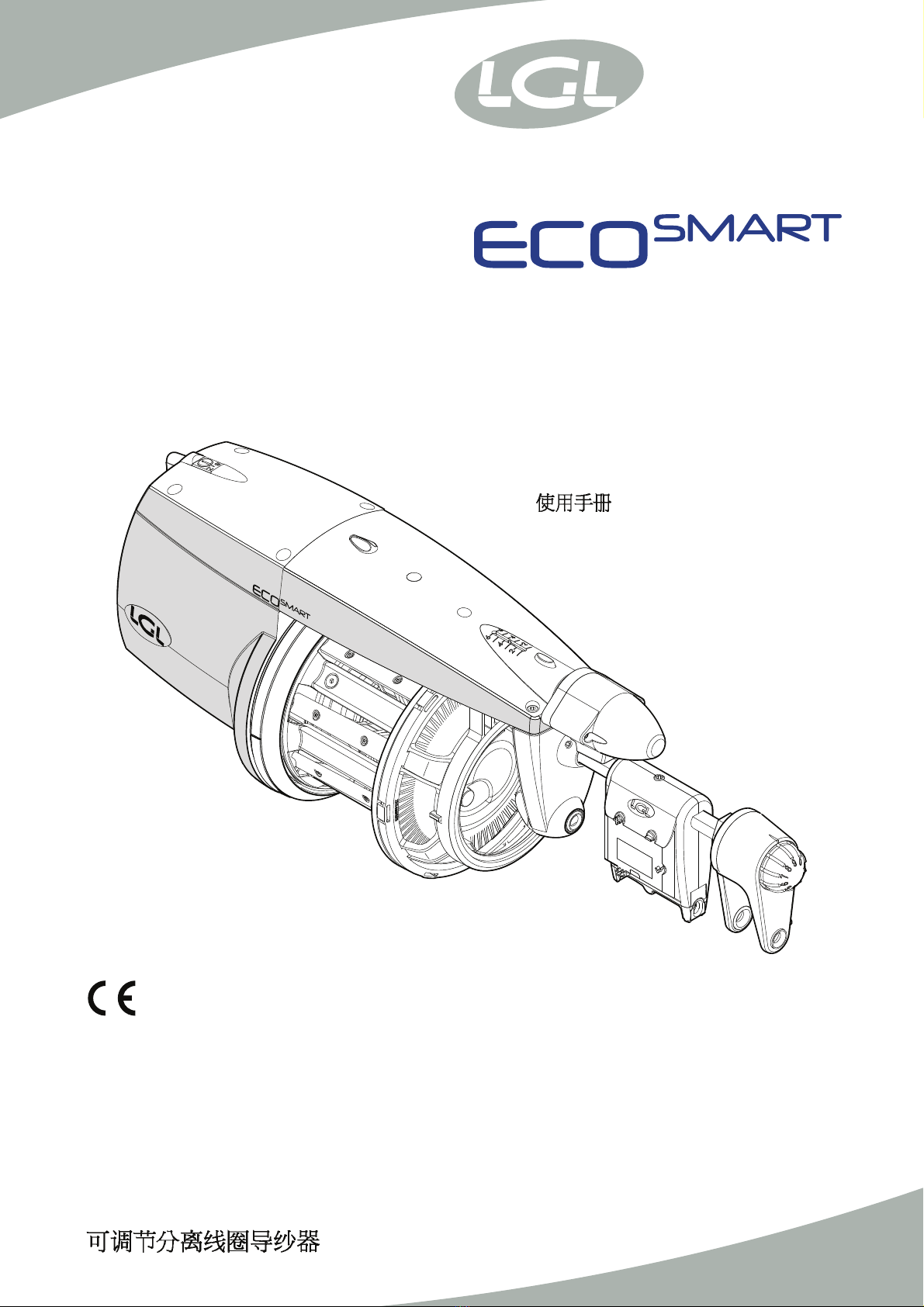

1 GENERAL FEATURES

1.1 Main parts - controls and adjustment points 9

1.2 Overall dimensions 10

1.3 Intended use - main features and specifications 11

1.4 Handling and storage 12

1.5 Input feeler 12

1.6 Optical output sensor 13

1.7 Yarn spool body winding reserve control feeler 13

2 INSTALLATION AND START-UP

2.1 Installation of the power control box 14

2.2 Can-Bus feature 16

2.3 Installation and start-up of the weft accumulator 16

3 THREADING AND ADJUSTMENTS

3.1 Threading of the weft accumulator with weft taker 17

3.2 Pneumatic threading 18

3.3 Speed adjustment 20

3.4 Tension adjustment 20

3.5 Setting the direction of rotation and adjusting the separation of the coils 21

3.6 Weft feeler height adjustment procedure 23

3.7 Three-feeler version 23

4 SPECIAL PROGRAMS

4.1 Special programs (fitted as standard on all yarn feeders) 25

5 MAINTENANCE AND COMPONENT REPLACEMENTS

5.1.1 Disassembly of the spool body 26

5.1.2 Removing single parts of spool body 28

5.2 Replacement of the electronic control board 30

5.3 Calibration of motor and optical sensors 31

6 MOUNTING THE TENSIONERS

6.1 Mounting the twm tension modulator 33

6.2 Mounting the bristle brush 34

6.3 Mounting the metal brush 35

7 APPLICATION FIELD FOR TENSIONERS

7.1 Application field for input tensioners 36

7.2 Application field for the “TWM” tension modulator 37

7.3 Application field for bristle brush tensioners 38

7.4 Application field for metal brush tensioners 39

7.5 Yarn count systems conversion table 40